Less-layer rhenium disulfide nanosheet/hollow carbon spheres for sodium-ion battery negative electrode material and preparation method thereof

A sodium ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of poor conductivity, low theoretical specific capacity, volume expansion effect, etc., and achieve high conductivity and buffering Volume effect, the effect of preventing sheet peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

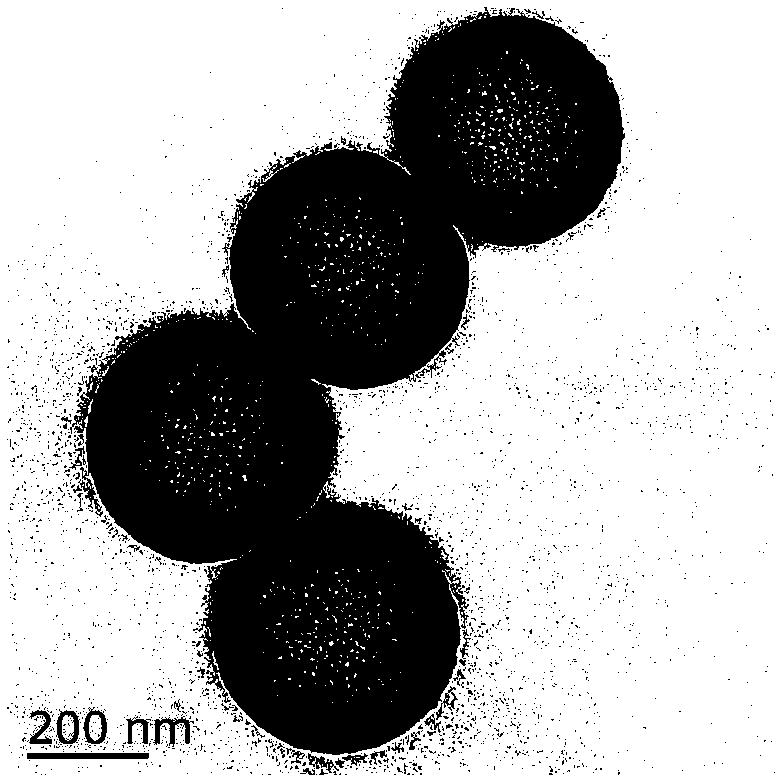

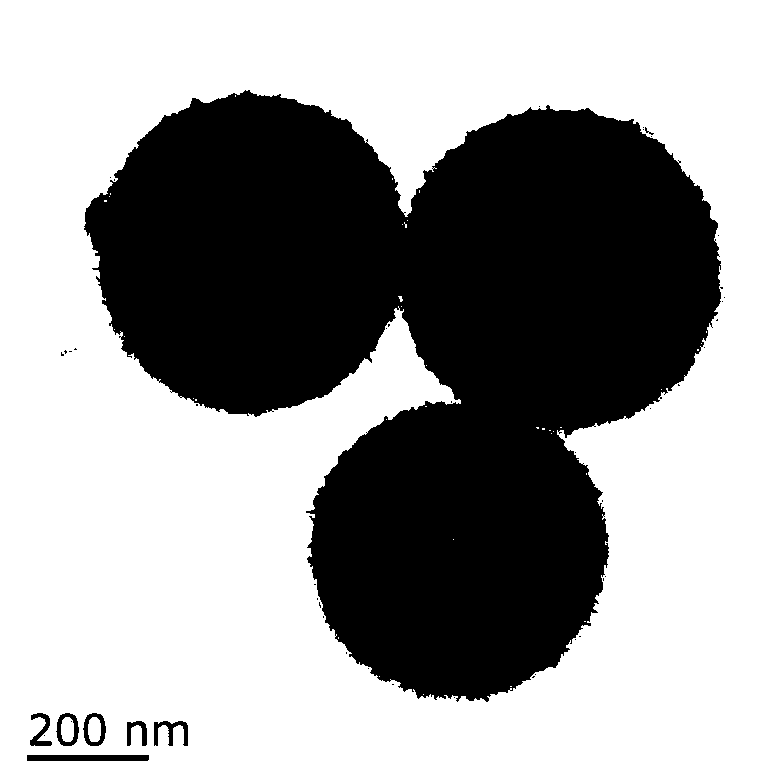

[0022] 1. Preparation of hollow porous carbon nanospheres:

[0023] Add 50 mL of absolute ethanol, 5 mL of deionized water, and 1 mL of ammonia water into the beaker in turn and perform magnetic stirring. At the same time, add 0.4 mL of tetraethyl orthosilicate to the above mixture, stir the mixture for a period of time, and weigh Add 0.2 g of resorcinol and 0.2 g of formaldehyde to the above mixed solution in sequence, and stir magnetically for 24 h at a water bath temperature of 30 °C. After the reaction was completed, it was centrifuged and washed to obtain a solid phase and then dried. Under the protection of argon, the dried product was calcined at 600°C for 5 hours at a heating rate of 2°C / min, and then the calcined product was placed in a water bath at 60°C. Etching with 2 M sodium hydroxide solution for 12 h. Finally, the etched product is centrifuged and washed, and the obtained solid phase is dried to obtain hollow porous carbon nanospheres. The obtained porous hol...

Embodiment 1

[0027] Dissolve 0.3 g of ammonium perrhenate and 0.3 g of thioacetamide solid in 70 mL of deionized water, ultrasonically, and at the same time add 0.15 g of hydrazine hydrate to mix evenly, and add 0.18 g of hollow porous carbon nanospheres to ultrasonically disperse in the above solution, Hydrothermal reaction at 80 °C for 1 h, after the reaction was completed, centrifuged and washed to obtain a solid phase and then dried, the dried product was calcined at 400 °C for 2 h under the protection of hydrogen / argon at a heating rate of 2 °C / min, and obtained Few-layer rhenium disulfide nanosheets / hollow carbon sphere nanocomposites (ReS 2 / C).

Embodiment 2

[0029] Preparation of few-layer rhenium disulfide nanosheets / hollow carbon sphere nanocomposites (ReS 2 / C)

[0030] Dissolve 0.3 g of ammonium perrhenate and 0.45 g of thioacetamide solid in 70 mL of deionized water, ultrasonically, and at the same time add 0.24 g of hydrazine hydrate to mix evenly, and add 0.24 g of hollow porous carbon nanospheres to ultrasonically disperse in the above solution, Hydrothermal reaction at 120 °C for 3 h, after the reaction was completed, centrifuged and washed to obtain a solid phase and then dried, the dried product was calcined at 600 °C for 4 h under the protection of hydrogen / argon at a heating rate of 2 °C / min, and obtained Few-layer rhenium disulfide nanosheets / hollow carbon sphere nanocomposites (ReS 2 / C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com