Method for preparing rhenium disulfide nanosheets

A technology of rhenium disulfide and nanosheets, applied in chemical instruments and methods, rhenium compounds, inorganic chemistry, etc., can solve problems such as high reaction temperature, complex control conditions, and danger, and achieve simple operation process, good repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take by weighing 0.5360 gram of ammonium perrhenate, 0.4170 gram of hydroxylamine hydrochloride and 0.6850 gram of thiourea and be dissolved in 60 milliliters of water and stir for 30 minutes, and the concentration of ammonium perrhenate, hydroxylamine hydrochloride and thiourea total substance is 0.28mol / L. Mixed solution; transfer the mixed solution to a 100 ml hydrothermal reactor liner, then put the hydrothermal reactor into an oven with a temperature of 240°C, and keep it warm for 24 hours to maintain the chemical reaction; after the reaction, Stop heating in the oven, take out the hydrothermal reaction kettle and cool it down to room temperature, then clean the product in the hydrothermal reaction kettle with water and alcohol, and dry it at 60°C to finally prepare rhenium disulfide nanosheets.

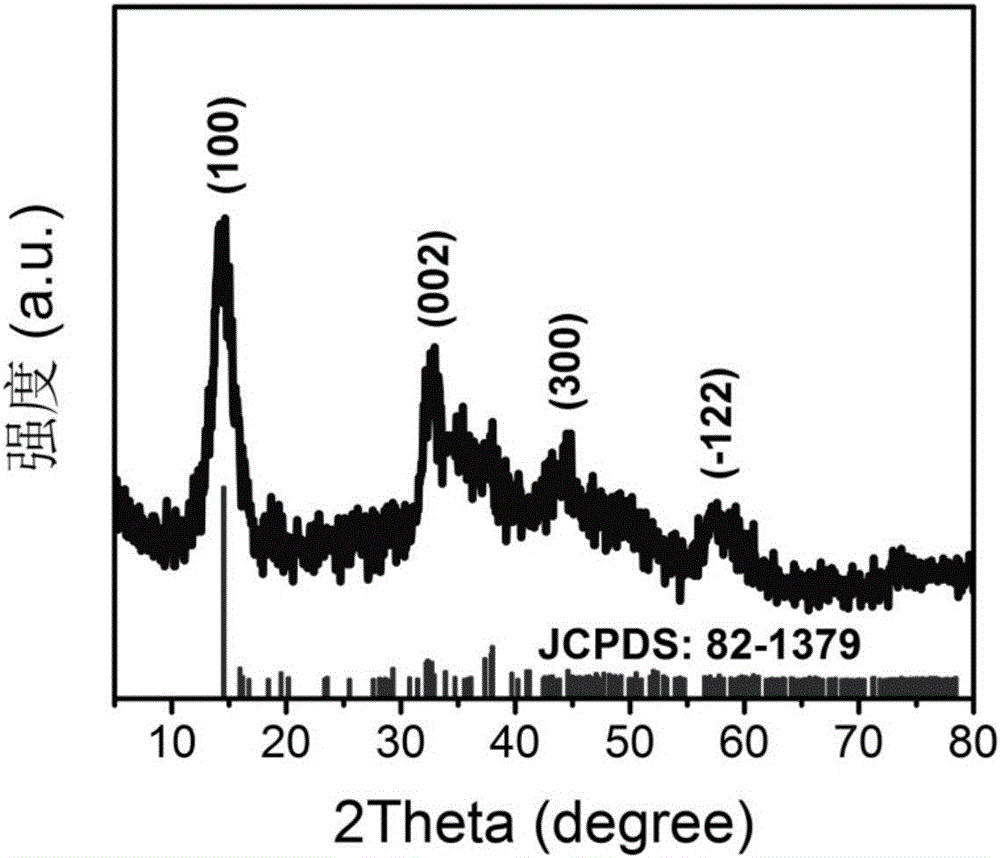

[0019] figure 1 For the X-ray diffraction pattern of the rhenium disulfide nanosheets prepared in this embodiment, from figure 1 It can be seen that the final synthesize...

Embodiment 2

[0021] Take by weighing 0.5360 gram of ammonium perrhenate, 0.1040 gram of hydroxylamine hydrochloride and 0.3045 gram of thiourea were dissolved in 60 milliliters of water and stirred for 30 minutes, and the amount concentration of ammonium perrhenate, hydroxylamine hydrochloride, and thiourea total substance was obtained as 0.13mol / L Mixed solution; transfer the mixed solution to a 100 ml hydrothermal reactor liner, then put the hydrothermal reactor into an oven with a temperature of 240°C and keep it warm for 6 hours to maintain the chemical reaction; after the reaction, Stop heating in the oven, take out the hydrothermal reaction kettle and cool it down to room temperature, then clean the product in the hydrothermal reaction kettle with water and alcohol, and dry it at 60°C to finally prepare rhenium disulfide nanosheets.

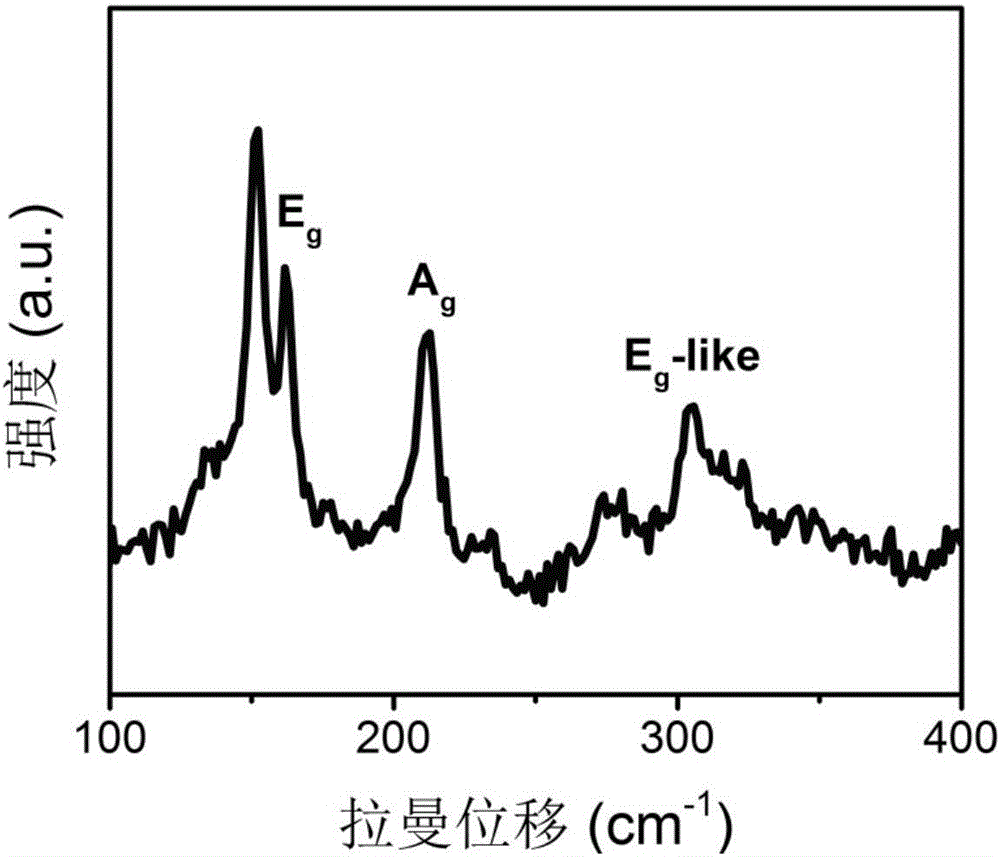

[0022] figure 2 The Raman spectrogram of the rhenium disulfide nanosheet prepared for this embodiment, from figure 2 It can be seen in the 161.7cm ...

Embodiment 3

[0024] Take by weighing 0.5360 gram of ammonium perrhenate, 0.6950 gram of hydroxylamine hydrochloride and 0.7612 gram of thiourea and be dissolved in 60 milliliters of water and stir for 30 minutes, and the concentration of ammonium perrhenate, hydroxylamine hydrochloride and thiourea total substance is 0.37mol / L. Mixed solution; transfer the mixed solution to a 100 ml hydrothermal reactor liner, then put the hydrothermal reactor into an oven with a temperature of 160°C, and keep it warm for 24 hours to maintain the chemical reaction; after the reaction, Stop heating in the oven, take out the hydrothermal reaction kettle and cool it down to room temperature, then clean the product in the hydrothermal reaction kettle with water and alcohol, and dry it at 60°C to finally prepare rhenium disulfide nanosheets.

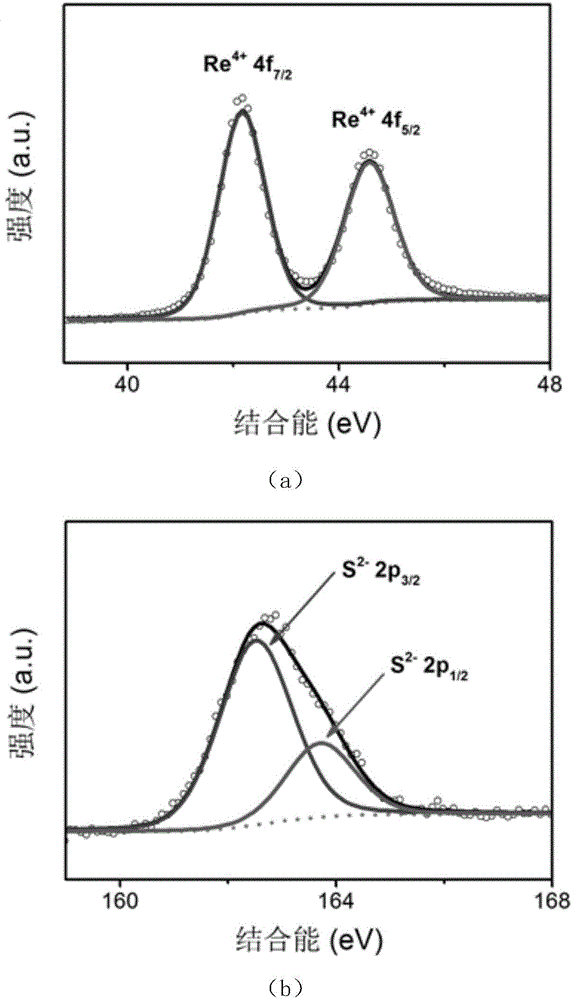

[0025] image 3 The X-ray photoelectron spectrum of rhenium disulfide prepared for the embodiment of the present invention can be seen from figure (a): the 4f valence sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com