Method for preparing ammonium perrhenate

A technology of ammonium perrhenate and perrhenic acid, applied in chemical instruments and methods, rhenium compounds, inorganic chemistry, etc., can solve the problems of molybdenum-rhenium separation difficulties, waste of resources, environmental pollution, etc., and achieve good economic value and environmental benefits , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

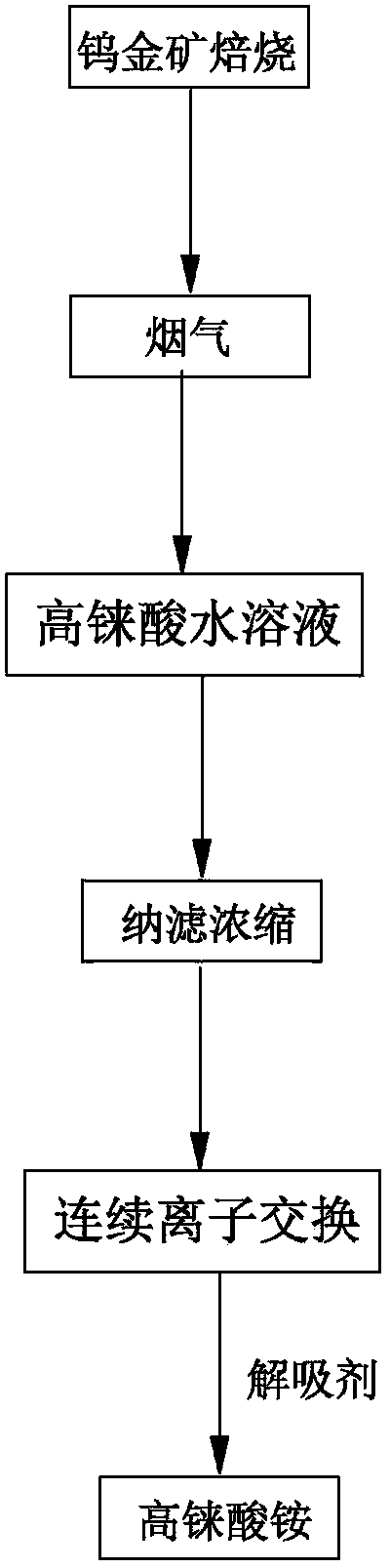

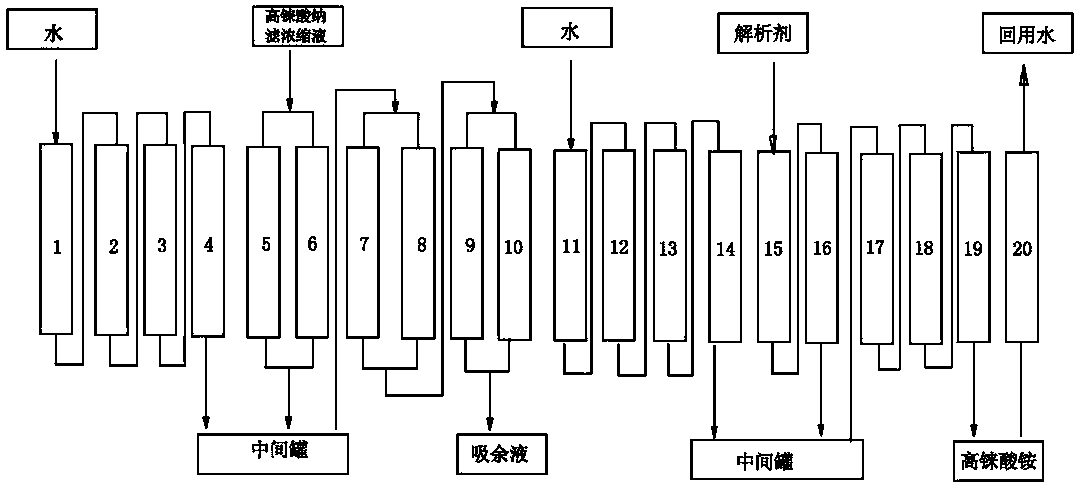

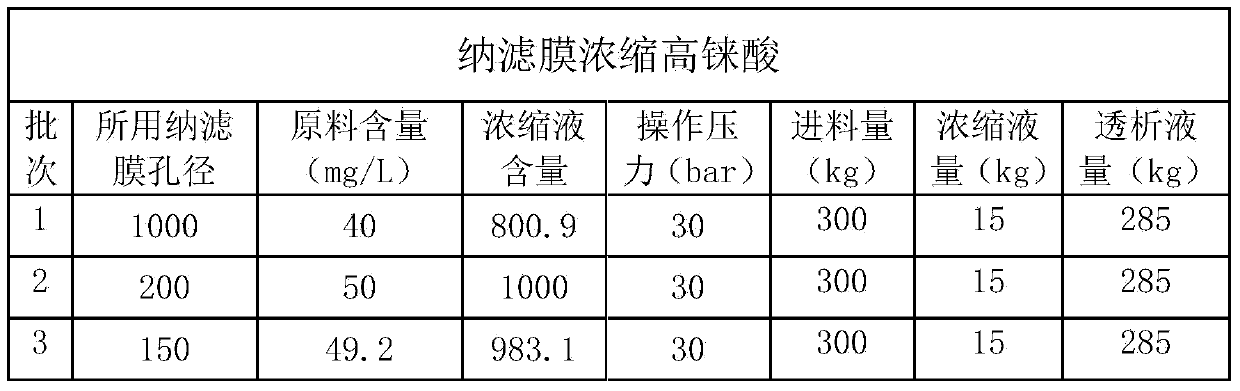

[0025] The method for preparing ammonium perrhenate described in the present invention is as figure 1 As shown, the tungsten-gold ore is roasted to produce flue gas. After the flue gas is dedusted, it is washed. The water produced by the washing contains H2SO4, H2SO3, SO2, H2MoO4, and H2ReO4. The content of H2ReO4 is 40-50mg / L. The washing water enters the nanofiltration membrane to concentrate, and the nanofiltration concentration results are as follows:

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com