Thiocyanate spectrophotometry method for detecting iron content of high-temperature alloy

A technology of superalloy and thiocyanate, applied in the field of chemical analysis, can solve the problems of poor stability and unsolved cobalt interference, and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the thiocyanate spectrophotometric method for iron content in superalloys according to the present invention will be described in detail with reference to exemplary embodiments.

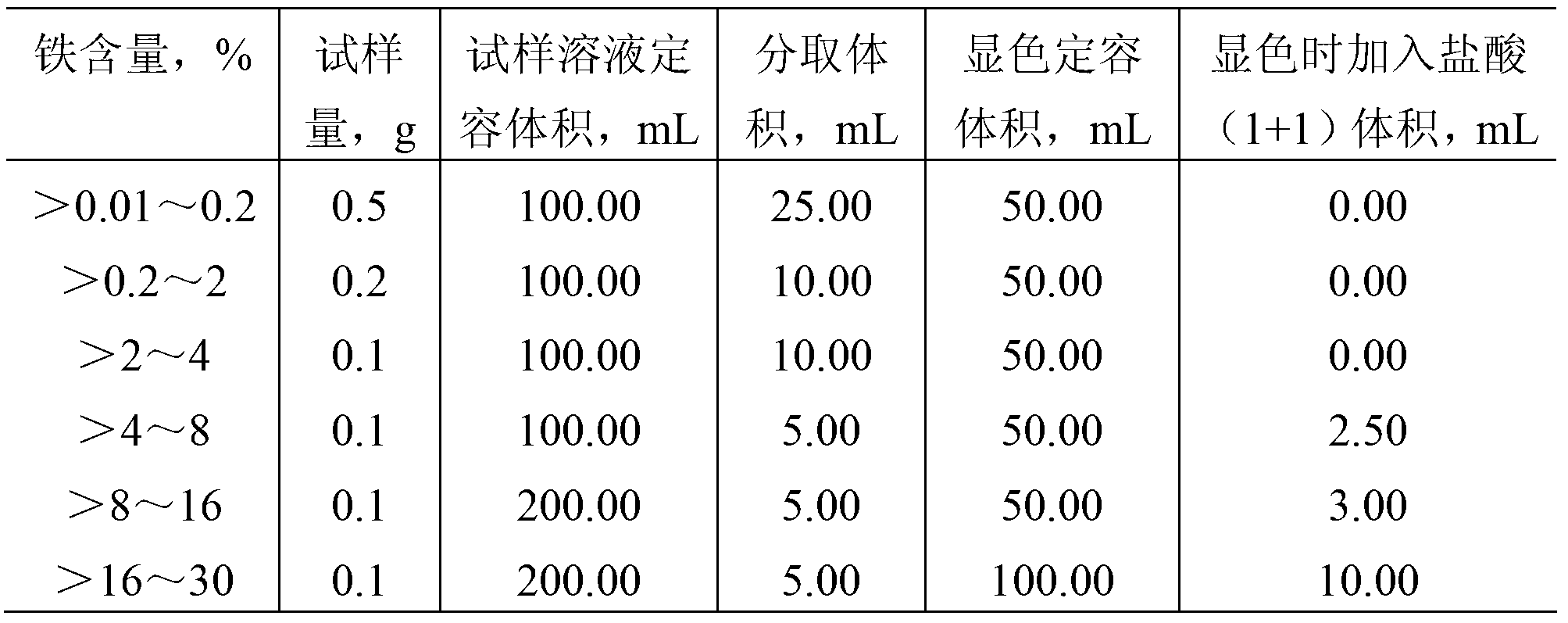

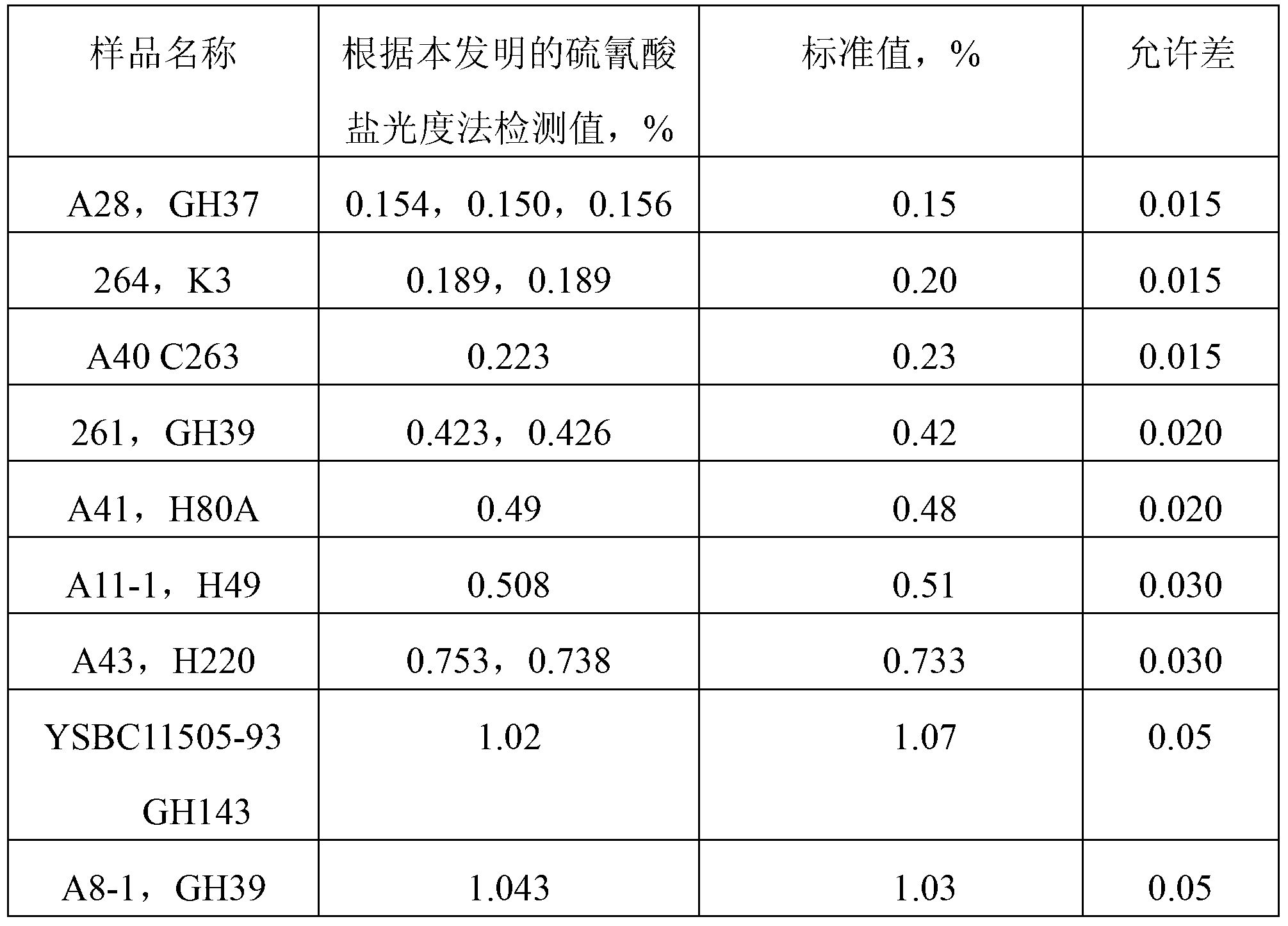

[0013] In view of the advantages of fast color development and non-interference of nickel when the thiocyanate photometry detects the iron content in the superalloy, the present invention solves the interference problem of cobalt, copper and vanadium in the detection of the superalloy by the thiocyanate photometry through research , so that the thiocyanate spectrophotometry can directly and accurately detect the iron content in high-temperature alloys containing cobalt, copper, and vanadium. The main technical idea is: after the sample is dissolved in acid, use perchloric acid to fume to oxidize chromium, add hydrochloric acid dropwise to evaporate most of the chromium, or directly decompose the sample with mixed acid of nitric acid and hydrochloric acid; adjust the solution to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com