Method for extracting ammonium thiocyanate from ammonia-process desulfurization waste liquid by oxidation process

An ammonia desulfurization and ammonium thiocyanate technology, applied in thiocyanic acid, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of expensive equipment maintenance, destruction of ammonium thiocyanate resources, and low added value. and other problems, to achieve the effect of simple and convenient component separation and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

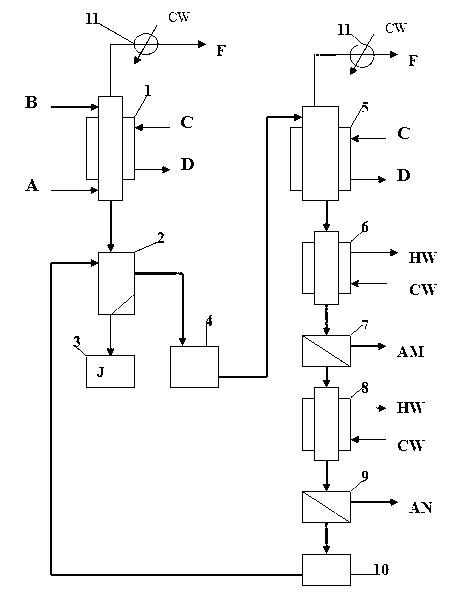

[0029] Process flow of the inventive method as figure 1 As shown, the main equipment of the process device includes an oxidizer 1 , an evaporative concentrator 5 , a first cooling crystallizer 6 , a second cooling crystallizer 8 , a first crystallizer 7 and a second crystallizer 9 . The specific implementation process of the inventive method is as follows:

[0030] The ammonia-based desulfurization waste liquid B sent from the desulfurization device is pumped into the oxidizer 1, and the amount of heating steam C is adjusted so that the temperature of the waste liquid in the container is within the range of 50-100 °C, and air or oxygen A is blown in at the same time , so that the waste liquid oxidation reaction. The amount of air or oxygen A blown in is 30 to 150 times the volume of the waste liquid, and the reaction time is controlled within the range of 60 to 120 minutes. The reaction oxidation solution is put into the precipitation separator 2 for static decantation and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com