Method of separating multi-ammonium compound salt

A separation method and technology of compound salt, which are applied in the preparation of ammonium salt, ammonium sulfate, thiosulfate/dithionite/polythionite, etc., can solve the problem of not described in detail and the purity is not very ideal. and other problems to achieve the effect of ensuring the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

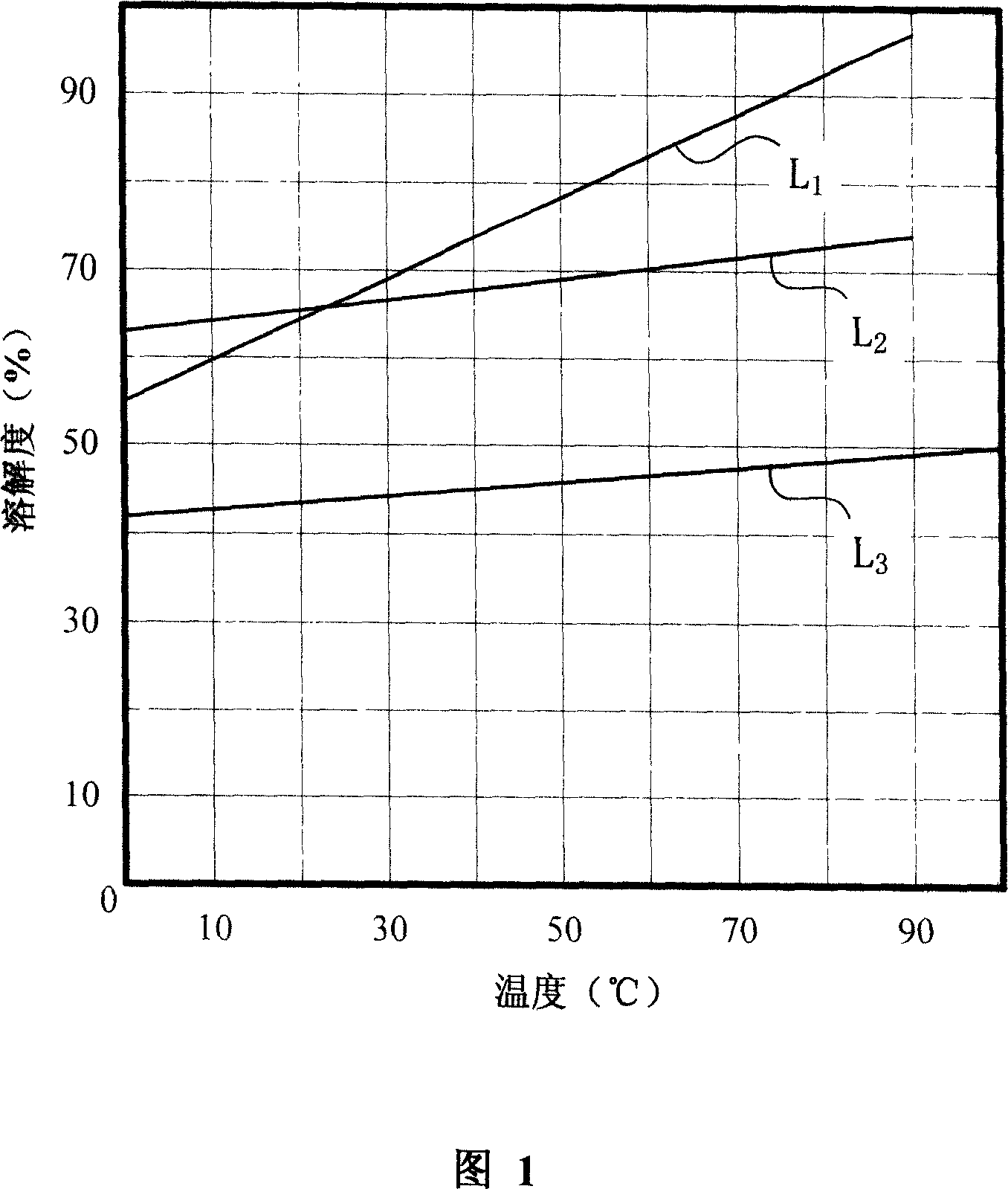

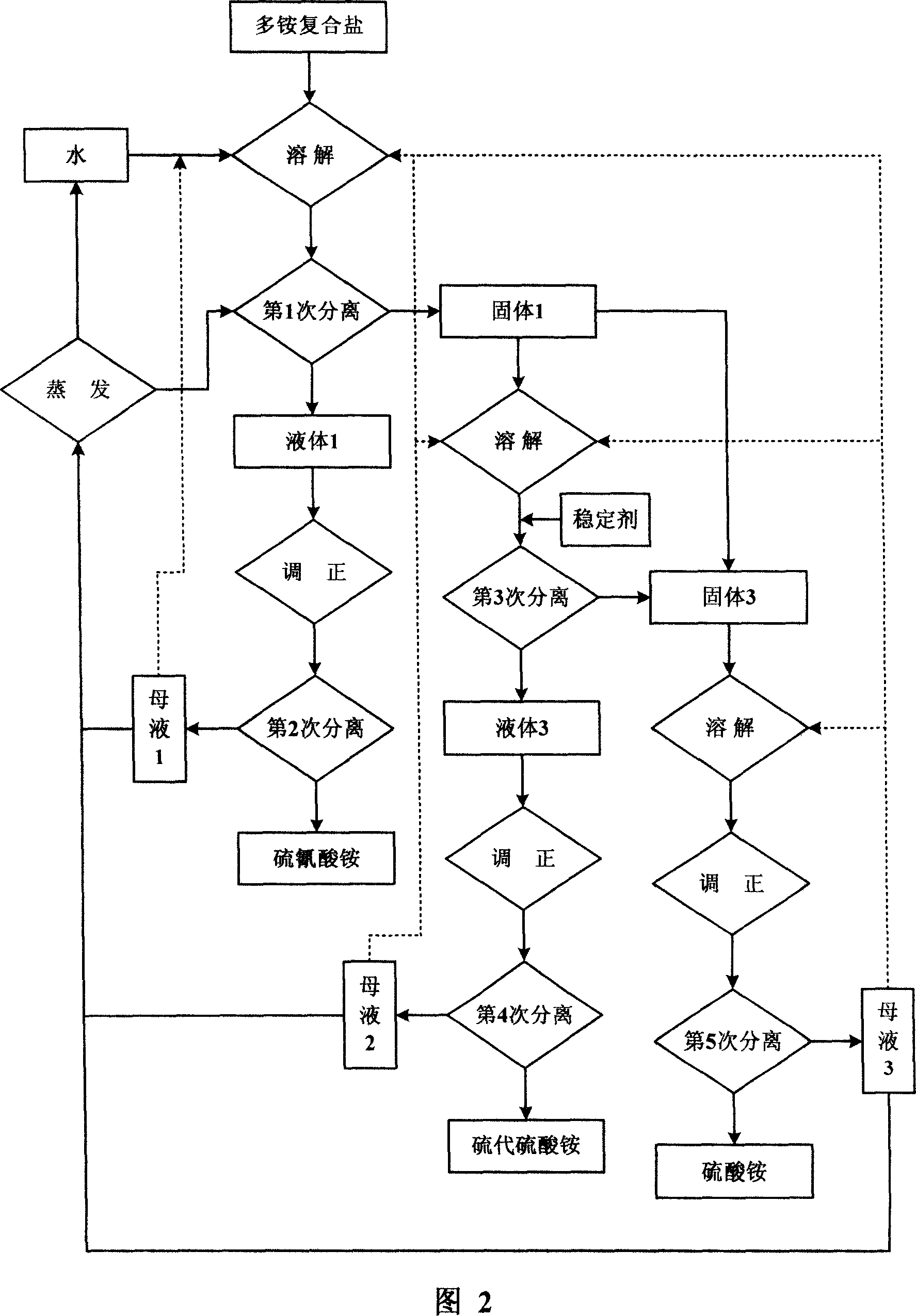

[0037] Polyammonium compound salt 1135g, which contains: NH 4 CNS, 37.62%; (NH 4 ) 2 S 2 o 3 , 46.66%; (NH 4 ) 2 SO 4 , 6.73%; H 2 O, 8.99%. Add 85g of water, dissolve at 70°C-80°C, and obtain 629ml of solution and 340g of solid through liquid-solid separation. The solution contains: NH 4 CNS, 51.16%, (NH 4 ) 2 S 2 o 3 , 27.22%, (NH 4 ) 2 SO 4 , 3.19%; solid contains: NH 4 CNS, 4.48%, (NH 4 ) 2 S 2 o 3 , 75.15%, (NH 4 ) 2 SO 4 , 11.59%.

[0038] The above 629ml solution was added with 135g of finished washing liquid, cooled to 25°C, and 141.6g of ammonium thiocyanate solid was obtained through liquid-solid separation, which contained: NH 4 CNS, 96.72%, (NH 4 ) 2 S 2 o 3 , 0.13%, (NH 4 ) 2 SO 4 , 0.42%, the separated mother liquor returns to dissolve the compound salt or evaporates; the above 340g solid is added with 65g of water, and an appropriate amount of ammonia is added as a stabilizer, dissolved below 95°C, and 257ml of the solution is obta...

Embodiment 2

[0040] Polyammonium compound salt 1000g, which contains: NH 4 CNS, 58.12%; (NH 4 ) 2 S 2 o 3 , 20.48%; (NH 4 ) 2 SO 4 , 12.72%; H 2 O, 8.68%. Add 660g of mother liquor, dissolve at 60°C-70°C, and obtain 1113ml of solution and 249g of solid through liquid-solid separation. The solution contains: NH 4 CNS, 53.42%, (NH 4 ) 2 S 2 o 3 , 22.33%, (NH 4 ) 2 SO 4 , 3.42%; solid contains: NH 4 CNS, 20.74%, (NH 4 ) 2 S 2 o 3 , 10.54%, (NH 4 ) 2 SO 4 , 54.40%.

[0041] The above 1113ml solution was added with 60g of finished washing liquid, cooled to 25°C, and 263.5g of ammonium thiocyanate solid was obtained through liquid-solid separation, which contained: NH 4 CNS, 97.52%, (NH 4 ) 2 S 2 o 3 , 0.07%, (NH 4 ) 2 SO 4 , 0.08%, the separated mother liquor returns to dissolve the compound salt; the above-mentioned 249g solid is added with 35ml of water, dissolved at 30°C-40°C, separated from liquid to solid at normal temperature, to obtain 111.07g of ammonium s...

Embodiment 3

[0043] Polyammonium compound salt 500g, which contains: NH 4 CNS, 47.44%; (NH 4 ) 2 S 2 o 3 , 26.81%; (NH 4 ) 2 SO 4 , 16.54%. Add 360g of mother liquor, dissolve at 60°C-80°C, and obtain 570ml of solution and 129g of solid through liquid-solid separation. The solution contains: NH 4 CNS, 47.85%, (NH 4 ) 2 S 2 o 3 , 27.04%, (NH 4 ) 2 SO 4 , 2.51%; solid contains: NH 4 CNS, 24.24%, (NH 4 ) 2 S 2 o 3 , 18.83%, (NH 4 ) 2 SO 4 , 47.46%.

[0044] The above 570ml solution was added with 84g of finished washing liquid, cooled to 30°C, and 96.7g of solid ammonium thiocyanate was obtained through liquid-solid separation, which contained: NH 4 CNS, 97.32%, (NH 4 ) 2 S 2 o 3 , 0.4%, (NH 4 ) 2 SO 4 , 0.38%, the separated mother liquor returns to dissolve the compound salt; the above-mentioned 129g solid adds 18ml of water, dissolves at 30°C-40°C, and separates the liquid and solid at normal temperature to obtain 49.5g of ammonium sulfate solid, which contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com