Nitrogen and sulfur two-component doped nano titanium dioxide with long-wave absorbing function and its preparing method

A nano-titanium dioxide, doped technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low absorption threshold and absorption limited to the ultraviolet region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

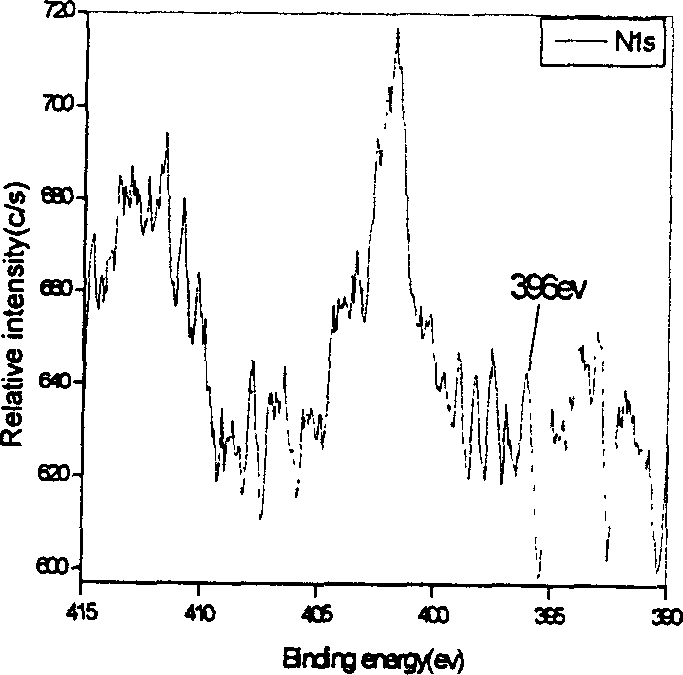

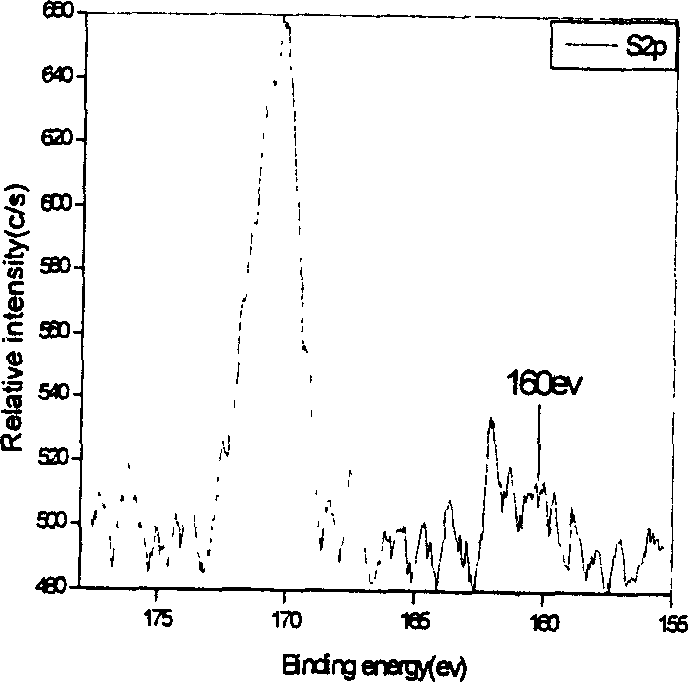

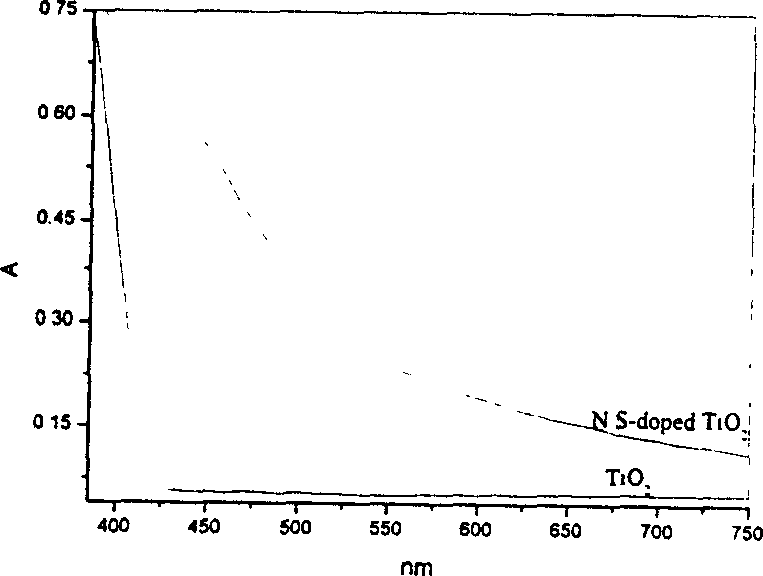

[0021] Embodiment 1, 5.6g urea and 7.2g thiourea are dissolved in the mixed solution of 25ml ethanol and 10ml hydrochloric acid, the ethanol solution (volume ratio is 1: 5), after the dropwise addition, continue to stir for 5 hours, then evaporate the prepared sample to dryness at a temperature of 100°C, take out the solid, grind it, and roast it in the air at a temperature of 450°C, the final solid is non-metallic Elemental nitrogen and sulfur co-doped nano titanium dioxide. Wherein the content of nitrogen is 0.65%, and the content of sulfur is 1.12%. refer to Picture 1-1 , Figure 1-2 and figure 2 : In the XPS spectrum of the obtained nano-titanium dioxide, the characteristic peak of the 2p electron binding energy of sulfur in the Ti-S bond is 160eV; the characteristic peak of the 1S electron binding energy of nitrogen in the Ti-N bond is 396eV; the ultraviolet / visible absorption spectrum It shows that the range of absorption edge of the nano-titanium dioxide reaches 55...

Embodiment 2

[0022] Embodiment 2, 5.0g ammonium chloride and 7.2g thiourea are dissolved in the mixed solution of 25ml ethanol and 10ml hydrochloric acid, the ethanolic solution of butyl titanate is added dropwise in this solution under the condition of constant stirring (volume ratio is 1:5), after the dropwise addition, continue to stir for 5 hours, then evaporate the prepared sample to dryness at a temperature of 100°C, take out the solid, grind it, and roast it in air at a temperature of 450°C, the final solid is Non-metal element nitrogen and sulfur co-doped nano titanium dioxide. Wherein the content of nitrogen is 1.16%, and the content of sulfur is 0.83%.

Embodiment 3

[0023] Embodiment 3, 5.6g urea and 7.1g ammonium thiocyanate are dissolved in the mixed solution of 25ml ethanol and 10ml hydrochloric acid, the ethanolic solution of butyl titanate is added dropwise in this solution under the condition of constant stirring (volume ratio is 1:5), after the dropwise addition, continue to stir for 5 hours, then evaporate the prepared sample to dryness at a temperature of 100°C, take out the solid, grind it, and roast it in air at a temperature of 450°C, the final solid is Non-metal element nitrogen and sulfur co-doped nano titanium dioxide. Wherein the content of nitrogen is 1.62%, and the content of sulfur is 0.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com