BiPO4-WO3 composite photocatalyst and preparation method thereof

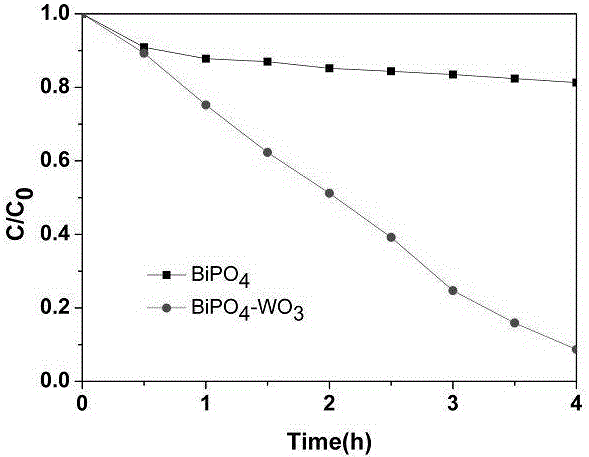

A bipo4-wo3, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low utilization rate of light, hindering application, reducing photocatalytic efficiency, etc. Achieve the effect of improving photocatalytic performance, improving separation efficiency, improving solar energy utilization and photon quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 0.005 mol of sodium tungstate and 0.005 mol of sodium chloride into deionized water and make up to 100mL to form a mixed solution of sodium tungstate and sodium chloride. After stirring for 30 minutes, adjust the pH value of the mixed solution with hydrochloric acid 0.5, continue to stir for 30 minutes, then transfer to the hydrothermal reaction kettle, then put the hydrothermal reaction kettle into the microwave digestion instrument and react with microwave at 180 ° C for 10 minutes, after the reaction is completed, it is cooled, washed and dried to obtain WO 3 powder;

[0018] (2) Prepare 100 mL of an aqueous solution of bismuth nitrate with a molar concentration of 0.1 mol / L, and add 0.01 mol of sodium dihydrogen phosphate and 0.01 mol of WO obtained in step (1) to the aqueous solution of bismuth nitrate under stirring conditions 3 powder;

[0019] (3) Stir the mixed solution obtained in step (1) for 1 hour at room temperature, then transfer it to a hydrothe...

Embodiment 2

[0021] (1) Add 0.01mol of sodium tungstate and 0.01mol of sodium chloride into deionized water and make up to 100mL to form a mixed solution of sodium tungstate and sodium chloride. After stirring for 30 minutes, adjust the pH of the mixed solution with hydrochloric acid 0.8, continue to stir for 30 minutes, then transfer to a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a microwave digestion apparatus and react with microwave at 180°C for 20 minutes, after the reaction is completed, it is cooled, washed and dried to obtain WO 3 powder;

[0022] (2) Prepare 100 mL of bismuth nitrate aqueous solution with a molar concentration of 0.2 mol / L, add 0.02 mol of sodium dihydrogen phosphate and 0.1 mol of WO obtained in step (1) to the bismuth nitrate aqueous solution under stirring conditions 3 powder;

[0023] (3) Stir the mixed solution obtained in step (2) for 1 hour at room temperature, then transfer it to a hydrothermal reaction kettle, then put ...

Embodiment 3

[0026] (1) Add 0.02mol of sodium tungstate and 0.02mol of sodium chloride to deionized water and make up to 100mL to form a mixed solution of sodium tungstate and sodium chloride. After stirring for 30 minutes, adjust the pH value of the mixed solution with hydrochloric acid 1.0, continue to stir for 30 minutes, then transfer to a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into a microwave digestion apparatus and react with microwave at 180°C for 30 minutes, after the reaction is completed, it is cooled, washed and dried to obtain WO 3 powder;

[0027] (2) Prepare 100 mL of bismuth nitrate aqueous solution with a molar concentration of 0.5 mol / L, add 0.05 mol of sodium dihydrogen phosphate and 0.5 mol of WO obtained in step (1) to the bismuth nitrate aqueous solution under stirring conditions 3 powder;

[0028] (3) Stir the mixed solution obtained in step (2) for 1 hour at room temperature, then transfer it to a hydrothermal reaction kettle, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com