Organic dye sensitized solar cell and preparation method thereof

A technology of solar cells and organic dyes, applied in the field of solar cells, can solve the problems of high cost and high price of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

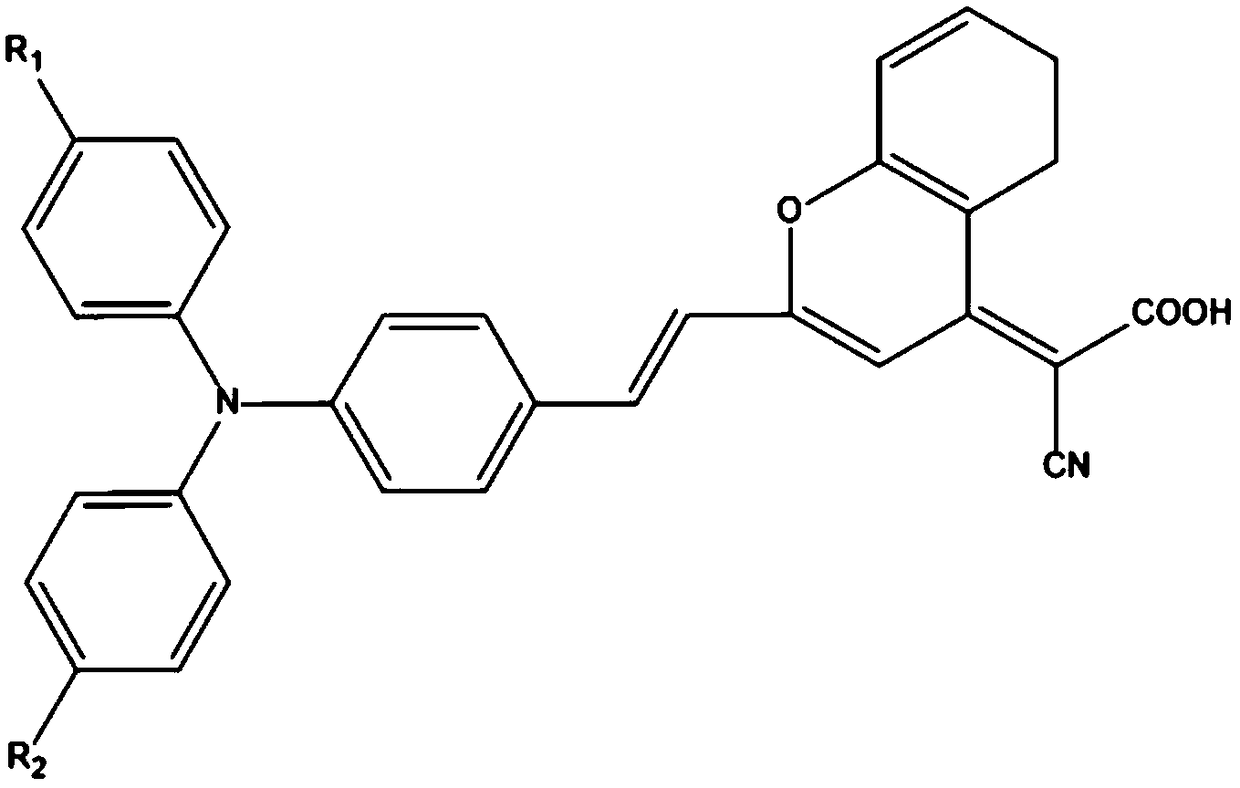

Method used

Image

Examples

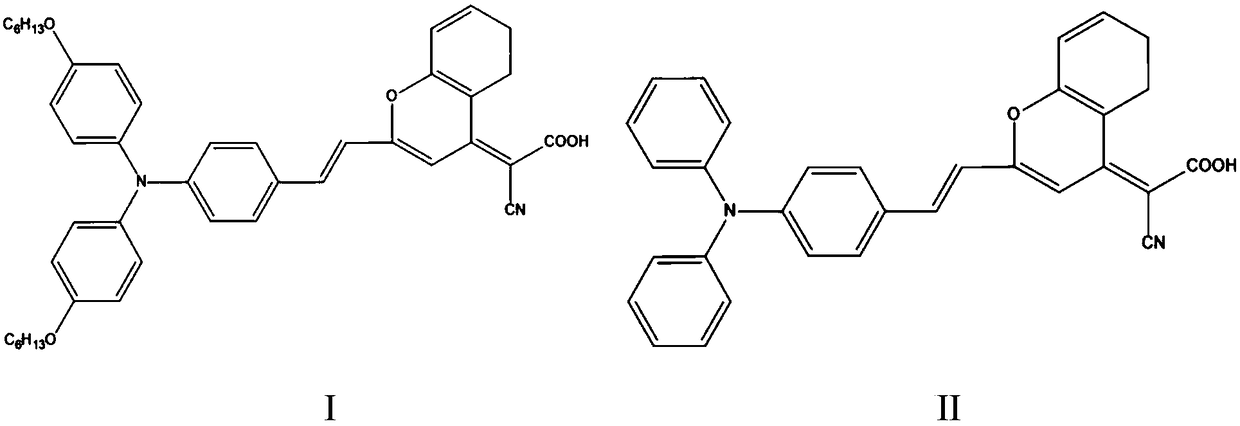

Embodiment 1

[0046] The preparation of embodiment 1 organic dye-sensitized solar cell I

[0047] Step 1. Preparation of organic dye-sensitized photoanode: screen-print 20nm titanium dioxide colloid on clean FTO glass, put it in a muffle furnace for 15, 15 and 30 minutes at 150, 350 and 500°C respectively, and cool to After 70°C, a titanium dioxide layer that is well combined with FTO is obtained, and different layer thicknesses can be obtained by multiple printings; the photoanode is immersed in a concentration of 2.5×10 -4 mol / L organic dye solution with D-π-A structure, add chenodeoxycholic acid as a co-adsorbent, soak for 24 hours, take it out, wash it with absolute ethanol, and dry it with nitrogen;

[0048] The organic dye of the D-π-A type structure is obtained by the following method:

[0049] (1) Preparation of bis-hexyloxytriphenylamine: In a 100ml single-mouth bottle, add 4.4g (80mmol) potassium hydroxide, 40ml dimethyl sulfoxide, 4.4g (20mmol) p-iodophenol and 2.8ml (20mmol) )...

Embodiment 2

[0060] Embodiment 2 Preparation of organic dye-sensitized solar cell II

[0061] Step 1. Preparation of organic dye-sensitized photoanode: screen-print 20nm titanium dioxide colloid on clean FTO glass, put it in a muffle furnace for 15, 15 and 30 minutes at 150, 350 and 500°C respectively, and cool to After 70°C, a titanium dioxide layer that is well combined with FTO is obtained, and different layer thicknesses can be obtained by multiple printings; the photoanode is immersed in a concentration of 2.5×10 -4 mol / L organic dye solution with D-π-A structure, add chenodeoxycholic acid as a co-adsorbent, soak for 24 hours, take it out, wash it with absolute ethanol, and dry it with nitrogen;

[0062] The organic dye of the D-π-A type structure is obtained by the following method:

[0063] (1) Preparation of triphenylamine monoaldehyde: under ice-bath conditions, slowly add 1ml (11.2mmol) of phosphorus oxychloride dropwise to a reaction flask filled with 15ml (194.5mmol) of N,N-di...

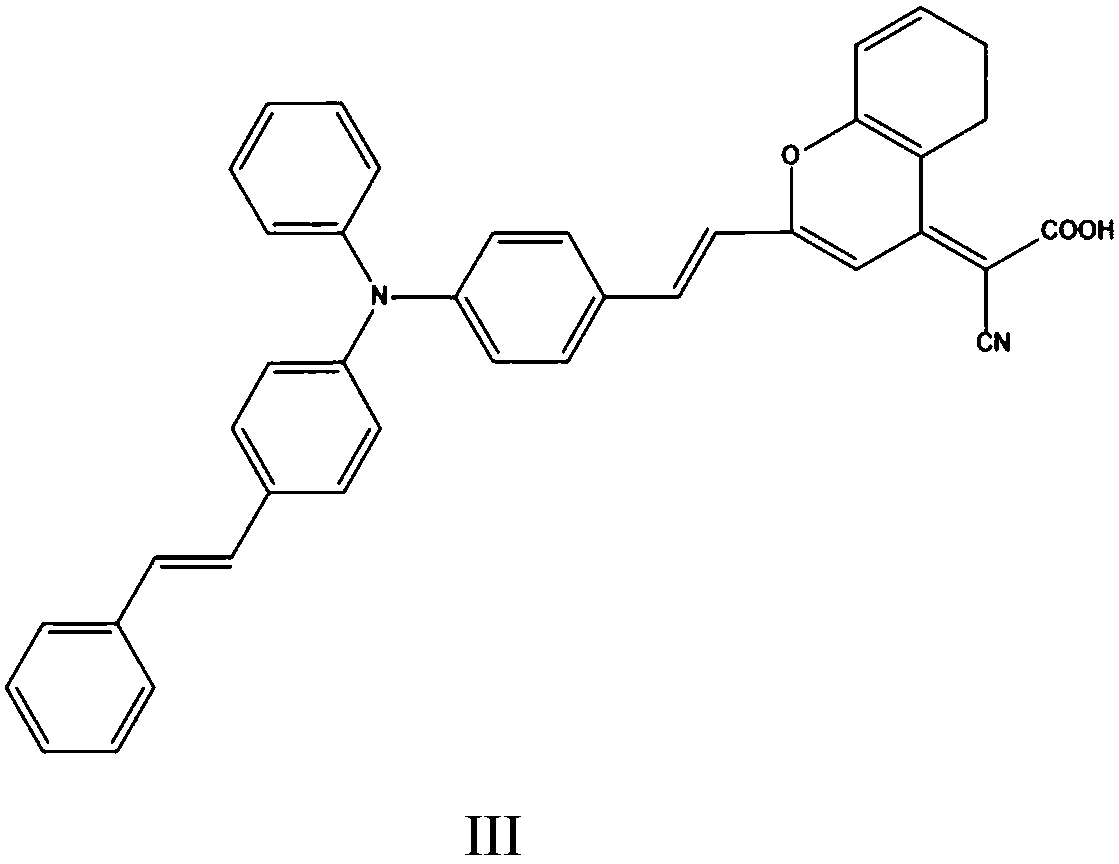

Embodiment 3

[0074] Embodiment 3 Preparation of organic dye-sensitized solar cell III

[0075] Step 1. Preparation of organic dye-sensitized photoanode: screen-print 20nm titanium dioxide colloid on clean FTO glass, put it in a muffle furnace for 15, 15 and 30 minutes at 150, 350 and 500°C respectively, and cool to After 70°C, a titanium dioxide layer that is well combined with FTO is obtained, and different layer thicknesses can be obtained by multiple printings; the photoanode is immersed in a concentration of 2.5×10 -4 mol / L organic dye solution with D-π-A structure, add chenodeoxycholic acid as a co-adsorbent, soak for 24 hours, take it out, wash it with absolute ethanol, and dry it with nitrogen;

[0076] The organic dye of the D-π-A type structure is obtained by the following method:

[0077] (1) Preparation of styrene-substituted triphenylamine monoaldehyde: Weigh 4.3g (9.9mmol) benyltriphenylphosphine bromide and add it to a 100ml three-necked flask, then add 60ml of dry THF, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com