Erbium-mono-doped C12A7 up-conversion material-doped dye-sensitized photoanode and preparation method and application thereof

A conversion material and dye sensitization technology, applied in the field of new energy materials, can solve the problems of sunlight loss and other problems, achieve the effect of improving battery efficiency, widening the response range, and improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

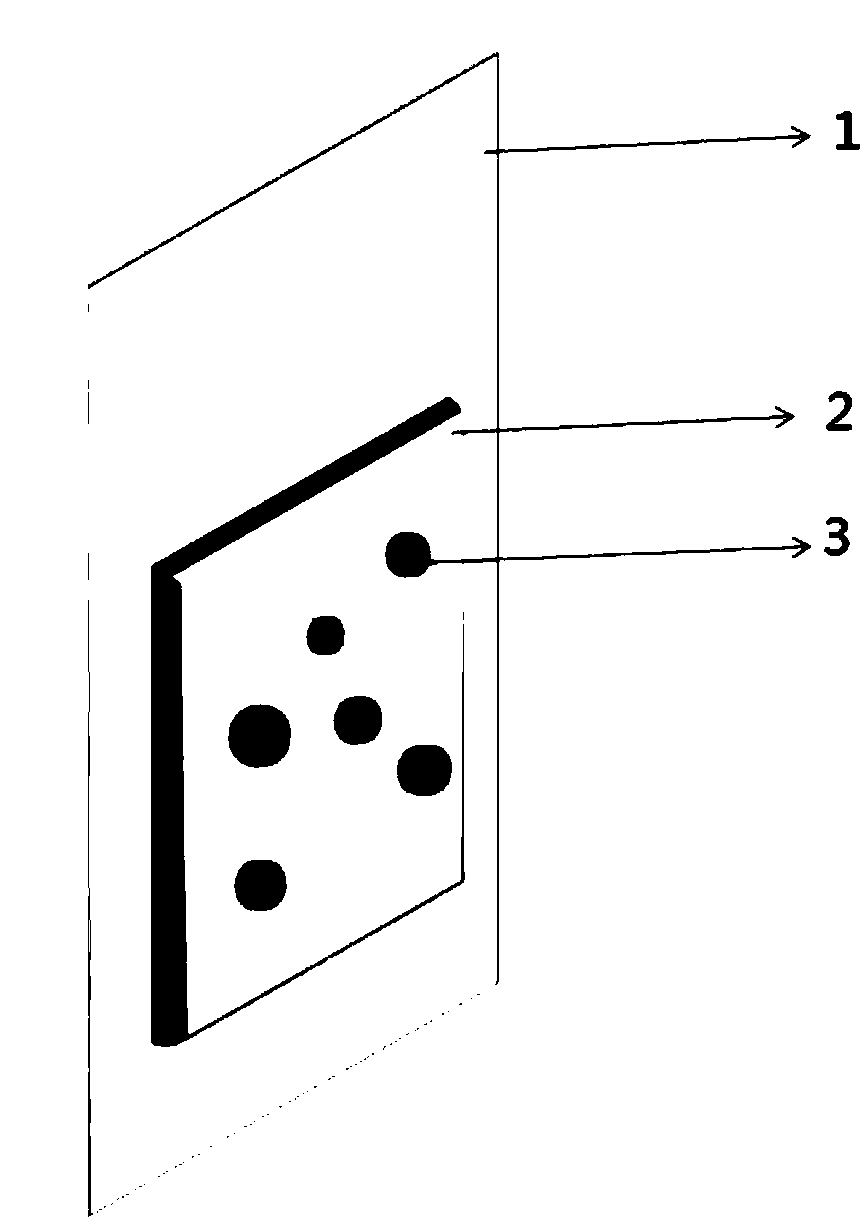

[0037] 1. Weigh 2.65g of ethyl cellulose and dissolve it in 23.67g of absolute ethanol to prepare solution A;

[0038] 2. 0.02g C12A7:Er and 1g titanium dioxide P25 were added in solution A, then 0.026gOP emulsifier, 0.294g acetylacetone and 3.73g terpineol were added to prepare solution B;

[0039] 3. Ultrasonicate solution B for 20 minutes;

[0040] 4. Place the ultrasonically treated solution B in a water bath, stir at a constant temperature of 80°C, and prepare colloid C after the absolute ethanol has evaporated;

[0041] 5. Fix the FTO conductive glass with 3M tape, and apply colloid C on the conductive glass with a glass rod;

[0042] 6. Place the conductive glass in a drying oven, dry it at 80°C for 10 minutes, then move it to a muffle furnace, and calcinate it at 450°C for 30 minutes;

[0043] 7. Soak the calcined electrode with dye for 24 hours, during which it should be protected from light;

[0044] 8. Wash the sensitized photoanode several times with absolute et...

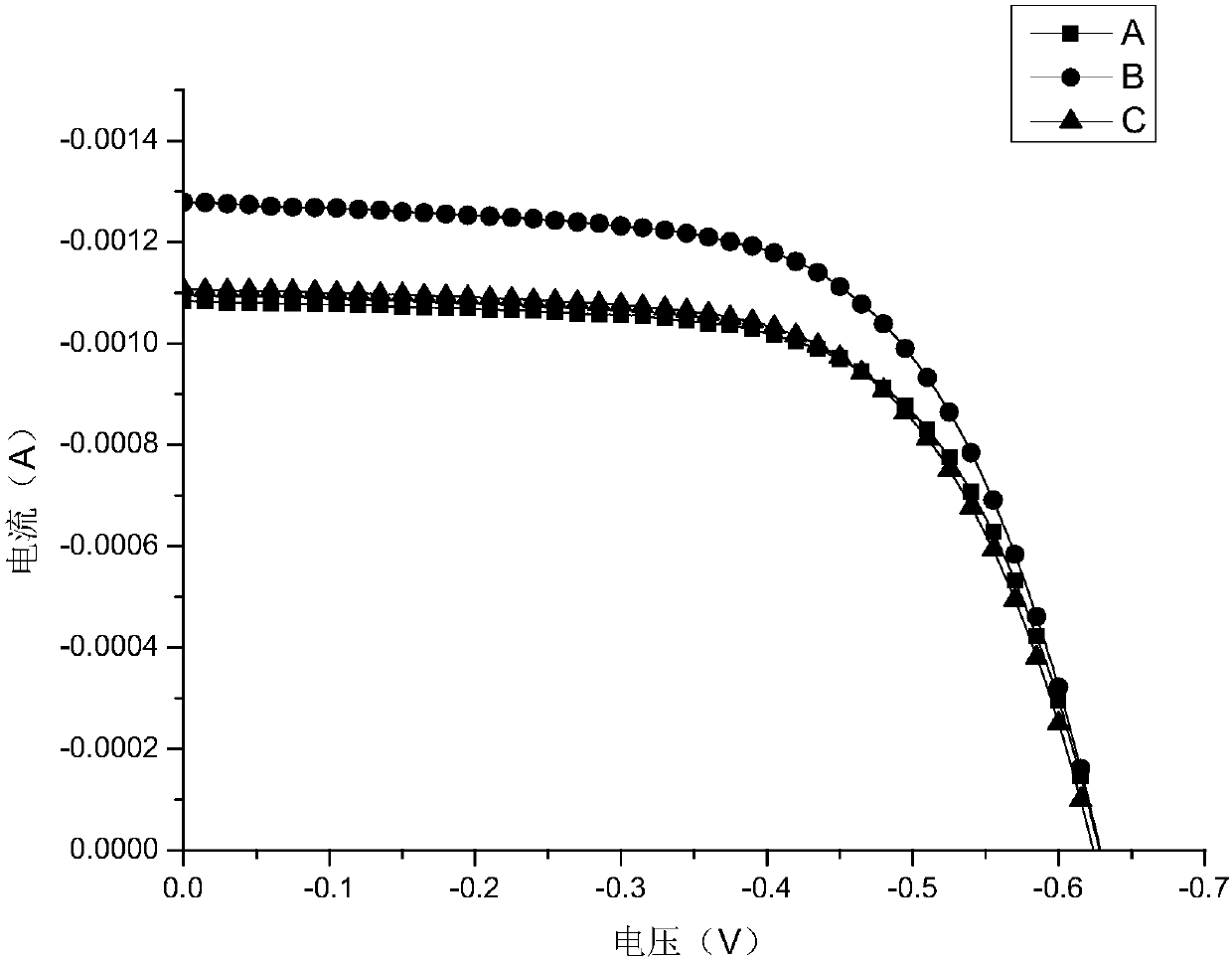

Embodiment 2

[0050] The difference between this embodiment and embodiment 1 is that the C12A7:Er in step 2 is 0.1 g.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is that the ultrasonic time in step 3 is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com