Method for recovering ammonium sulfate and ammonium thiocyanate from desulfuration waste liquor

A desulfurization waste liquid, ammonium thiocyanate technology, applied in the direction of thiocyanate, ammonium sulfate, etc., can solve the problem of not considering the influence of ammonium sulfate, and achieve the effect of reducing the circulation amount, improving the desulfurization efficiency, and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

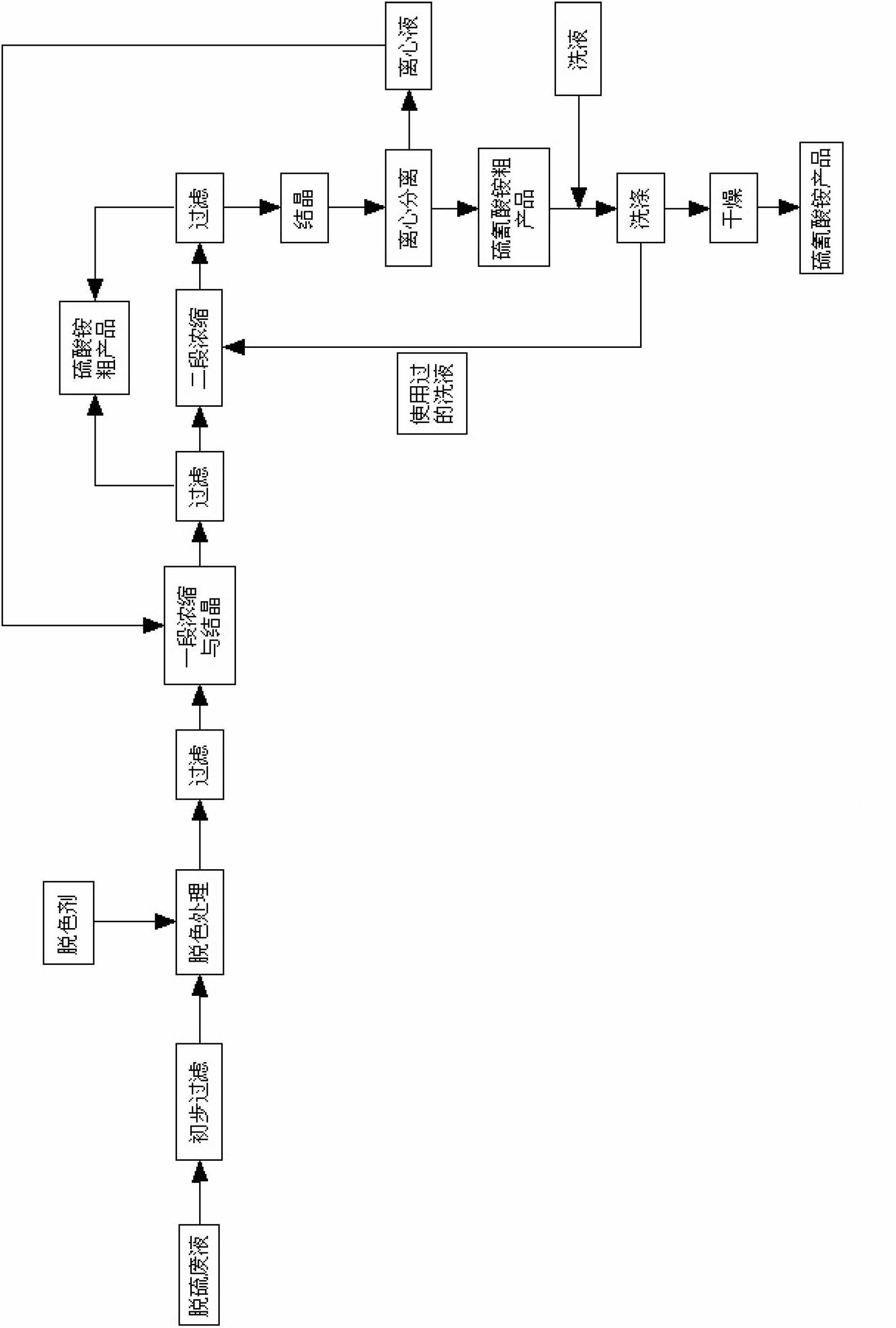

Image

Examples

Embodiment 1

[0023] Take coke oven gas desulfurization waste liquid 1100g [from Hebei China Coal Sunrise Coking Co., Ltd., where NH 4 SCN content 23.21wt%; (NH 4 ) 2 SO 4 Content 9.95wt%; (NH 4 ) 2 S 2 o 3 Content 0.83wt%], put it into the settling kettle and let it stand naturally for 8h. After filtering to remove solid particles, the desulfurization waste liquid after preliminary filtration was placed in a decolorization kettle, and then 10 g of activated carbon [purchased from Tianjin Guangfu Science and Technology Development Co., Ltd.] was added to decolorize at 60°C for 90 minutes and then filtered. Put the filtered mother liquor in a first-stage concentrator to concentrate under reduced pressure, the vacuum degree is 0.085MPa, and the concentration temperature is 75°C. After concentrating, 640 g of dehydration was obtained to obtain 460 g of once-concentrated slurry. Send the concentrated slurry into a crystallization tank at 50°C for heat preservation and crystallization fo...

Embodiment 2

[0025] Take coke oven gas desulfurization waste liquid 1100g [from Hebei China Coal Sunrise Coking Co., Ltd., where NH 4 SCN content 23.61wt%; (NH 4 ) 2 SO 4 Content 10.01wt%; (NH 4 ) 2 S 2 o 3Content 1.02wt%], put it into the settling kettle and let it stand naturally for 10h. After filtering to remove solid particles, the desulfurization waste liquid after preliminary filtration was placed in a decolorization kettle, and then 8g of coal ash [purchased from Xingtai Xuyang Coking Co., Ltd.] was added, decolorized at 60°C for 90 minutes, and then filtered. Put the filtered mother liquor in a first-stage concentrator to concentrate under reduced pressure, the vacuum degree is 0.085MPa, and the concentration temperature is 75°C. Concentrate and dehydrate 610g to obtain 490g of a concentrated slurry. Send the concentrated slurry into a 50°C first-stage crystallization tank for heat preservation and crystallization for 90 minutes, then filter the slurry to obtain 115g of am...

Embodiment 3

[0027] Take coke oven gas desulfurization waste liquid 1100g [from Hebei China Coal Sunrise Coking Co., Ltd., where NH 4 SCN content 22.68wt%; (NH 4 ) 2 SO 4 Content 10.21wt%; (NH 4 ) 2 S 2 o 3 Content 1.13wt%], put it into the settling kettle and let it stand naturally for 8h. After removing the solid particles by filtration, the desulfurization waste liquid after preliminary filtration was placed in a decolorization kettle, and then 10 g of coke particles [purchased from Xingtai Xuyang Coking Co., Ltd.] were added, decolorized at 60°C for 90 minutes, and then filtered. Put the filtered mother liquor in a first-stage concentrator to concentrate under reduced pressure, the vacuum degree is 0.085MPa, and the concentration temperature is 75°C. Concentrate and dehydrate 650g to obtain 450g of once-concentrated slurry. Send the concentrated slurry into a crystallization tank at 50°C for 90 minutes of heat preservation and crystallization, and then filter the slurry to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com