Preparation method of buprofezin

A technology of buprofezin and solvents, which is applied in the field of preparation of pesticide raw materials, can solve the problems of difficulty in raw material procurement and treatment of three wastes, and achieve the effects of reduced risk, low cost and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

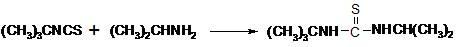

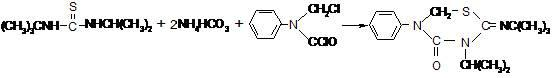

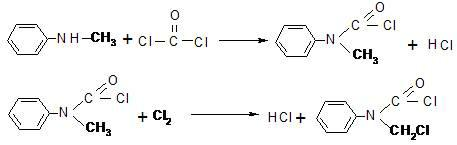

Method used

Image

Examples

Embodiment 1

[0024] Example 1. A method for preparing buprofezin, in which chlorobenzene is uniformly used as a solvent in all reaction steps requiring a solvent in the process of preparing buprofezin.

Embodiment 2

[0025] Example 2. A kind of preparation method of Buprofezin described in embodiment 1, concrete steps are as follows:

[0026] (1) Preparation of tert-butyl isothiocyanate: Add ammonium thiocyanate to water, the weight ratio of ammonium thiocyanate to water is 1:0.5, stir to dissolve; then add tert-butanol, stir for 10 minutes , the molar ratio of tert-butanol to ammonium thiocyanate is 1:0.9; the temperature is slowly raised to 70°C, and then industrial hydrochloric acid is added dropwise under reflux for 1 hour, and the molar ratio of tert-butanol to hydrochloric acid is 1: 1. After the dropwise addition, keep warm for 2 hours under reflux; then lower the temperature to 40°C, separate layers, and the acidic wastewater goes to the wastewater treatment tank, and the upper oil layer is washed with alkaline aqueous solution. The molar ratio is 1:0.1, and then washed with water to pH6.8, the light yellow oil layer liquid is returned to the reaction kettle equipped with the refl...

Embodiment 3

[0030] Example 3. A kind of preparation method of Buprofezin described in embodiment 1, concrete steps are as follows:

[0031](1) Preparation of tert-butyl isothiocyanate: Add ammonium thiocyanate to water, the weight ratio of ammonium thiocyanate to water is 1:2, stir to dissolve; then add tert-butanol and stir for 40 minutes , the mol ratio of tert-butanol to ammonium thiocyanate is 1: 1.2; slowly warming up to 90°C, then dropwise add industrial hydrochloric acid under reflux, the time of addition is 3 hours, the mol ratio of tert-butanol to hydrochloric acid is 1: 2.0, keep warm for 4 hours under reflux after the dropwise addition; then cool down to 70°C, stratify, acid waste water goes to the waste water treatment tank, and the upper oil layer is washed with alkaline aqueous solution, the alkaline substances in the alkaline aqueous solution are mixed with tert-butanol The molar ratio is 1: 0.5, and then washed to pH7.2, the light yellow oil layer liquid is returned to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com