Chemical for cleaning boiler, using method and cleaning device thereof

A boiler cleaning and medicament technology, which is applied in the coating process of metal materials, etc., can solve the problems of boiler safety operation, easy to cause acid corrosion, and unstable performance, etc., and achieve the effects of excellent passivation effect, low toxicity, and easy source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The medicament used for boiler cleaning in this embodiment includes corrosion-inhibiting pickling agent, rinsing agent and passivating agent; the corrosion-inhibiting pickling agent is composed of the following mass percentage components: 1,3,5, 7 Tetraazaadamantane 0.25%, ethylenediaminetetraacetic acid 0.2%, hydrochloric acid 5.0%, phosphoric acid 2.0%, fluosilicic acid 2.5%, hydrazine hydrate 0.1%, sodium silicate 0.08%, hexadecyldimethylbenzyl ammonium chloride 0.1%, ammonium thiocyanate 0.08%, sodium dodecylbenzene sulfonate 0.1%, and the balance is water; the rinse agent is a citric acid solution with a mass percentage of 0.1% to 0.2%. Or analytically pure ammonia water to adjust the pH value to 4; the passivating agent is composed of the following components in mass percentage: ethylenediamine 0.045%, formaldehyde 0.04%, diammonium hydrogen phosphate 0.05%, hydrogen peroxide 0.6%, nitrous acid Sodium 0.04%, the balance is water; adjust the pH value of the solutio...

Embodiment 2

[0077] The medicament used for boiler cleaning in this embodiment includes corrosion-inhibiting pickling agent, rinsing agent and passivating agent; the corrosion-inhibiting pickling agent is composed of the following mass percentage components: 1,3,5, 7 Tetraazaadamantane 0.3%, ethylenediaminetetraacetic acid 0.1%, hydrochloric acid 3.0%, phosphoric acid 3.0%, fluosilicic acid 2.0%, hydrazine hydrate 0.15%, sodium silicate 0.1%, hexadecyldimethylbenzyl 0.2% ammonium chloride, 0.06% ammonium thiocyanate, 0.12% sodium dodecylbenzenesulfonate, and the balance is water; Or analytically pure ammonia to adjust the pH value to 4; the passivator consists of the following components in mass percentage: 0.05% ethylenediamine, 0.05% formaldehyde, 0.06% diammonium hydrogen phosphate, 0.7% hydrogen peroxide, nitrous acid Sodium 0.02%, the balance is water; adjust the pH value of the solution to 8.5-9.0 with an appropriate amount of ammonia water.

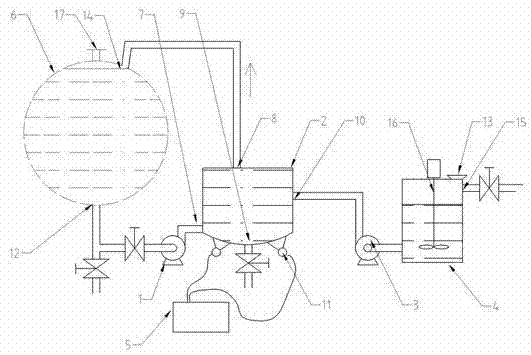

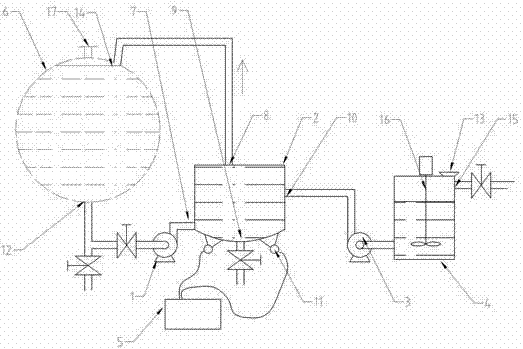

[0078] The supporting cleaning device o...

Embodiment 3

[0081] The medicament used for boiler cleaning in this embodiment includes corrosion-inhibiting pickling agent, rinsing agent and passivating agent; the corrosion-inhibiting pickling agent is composed of the following mass percentage components: 1,3,5, 7 Tetraazaadamantane 0.35%, ethylenediaminetetraacetic acid 0.15%, hydrochloric acid 8.0%, phosphoric acid 5.0%, fluorosilicic acid 2.0%, hydrazine hydrate 0.12%, sodium silicate 0.05%, hexadecyldimethylbenzyl 0.15% ammonium chloride, 0.08% ammonium thiocyanate, 0.15% sodium dodecylbenzenesulfonate, and the balance is water; the rinse agent is a citric acid solution with a mass percentage of 0.1% to 0.2%. Or analytically pure ammonia water to adjust the pH value to 4; the passivator consists of the following components in mass percentage: ethylenediamine 0.04%, formaldehyde 0.06%, diammonium hydrogen phosphate 0.03%, hydrogen peroxide 0.65%, nitrous acid Sodium 0.03%, the balance is water; adjust the pH value of the solution to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com