Method for treating ammonia desulfurization waste liquid by oxidation method

A technology for ammonia desulfurization and desulfurization waste liquid, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, separation methods, etc., can solve the problems of ammonium thiocyanate resource destruction, expensive equipment maintenance costs, expensive materials, etc., to achieve Simplified process flow, simple and convenient component separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

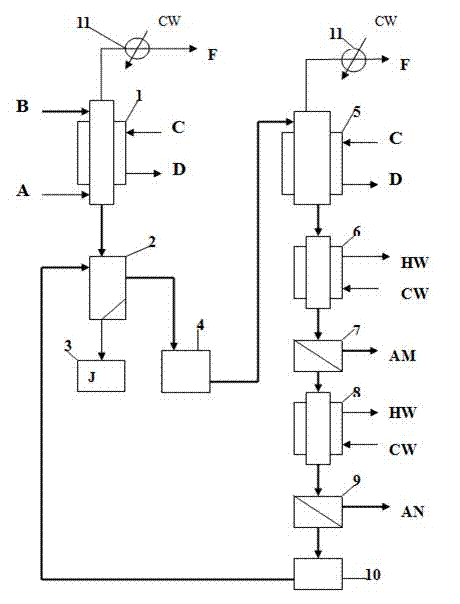

[0028] The process flow of the method of the present invention is as follows figure 1 As shown, the main equipment of the process device includes an oxidizer 1, an evaporation concentrator 5, a first cooling crystallizer 6, a second cooling crystallizer 8, a first crystal separator 7 and a second crystal separator 9. The specific implementation process of the method of the invention is as follows:

[0029] The ammonia desulfurization waste liquid B to be processed from the desulfurization device is pumped into the oxidizer 1, and the amount of heating steam C is adjusted to make the temperature of the waste liquid in the container within the range of 50-100oC, while blowing in air or oxygen A, Oxidize the waste liquid. The blowing amount of air or oxygen A is 30 to 150 times the volume of the waste liquid, and the reaction time is controlled within the range of 60 to 120 minutes. The reaction oxidation liquid is put into the sedimentation separator 2 for static decant separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com