Process for recycling inorganic salt from wastewater for desulfurization and decyanation of coke oven gas

A technology of desulfurization, decyanation and coke oven gas, which is applied in the field of coal coking, can solve the problems of low product recovery rate, waste water, waste residue generation, waste water salt separation, etc., and achieve scientific and reasonable process flow, huge social benefits, and easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

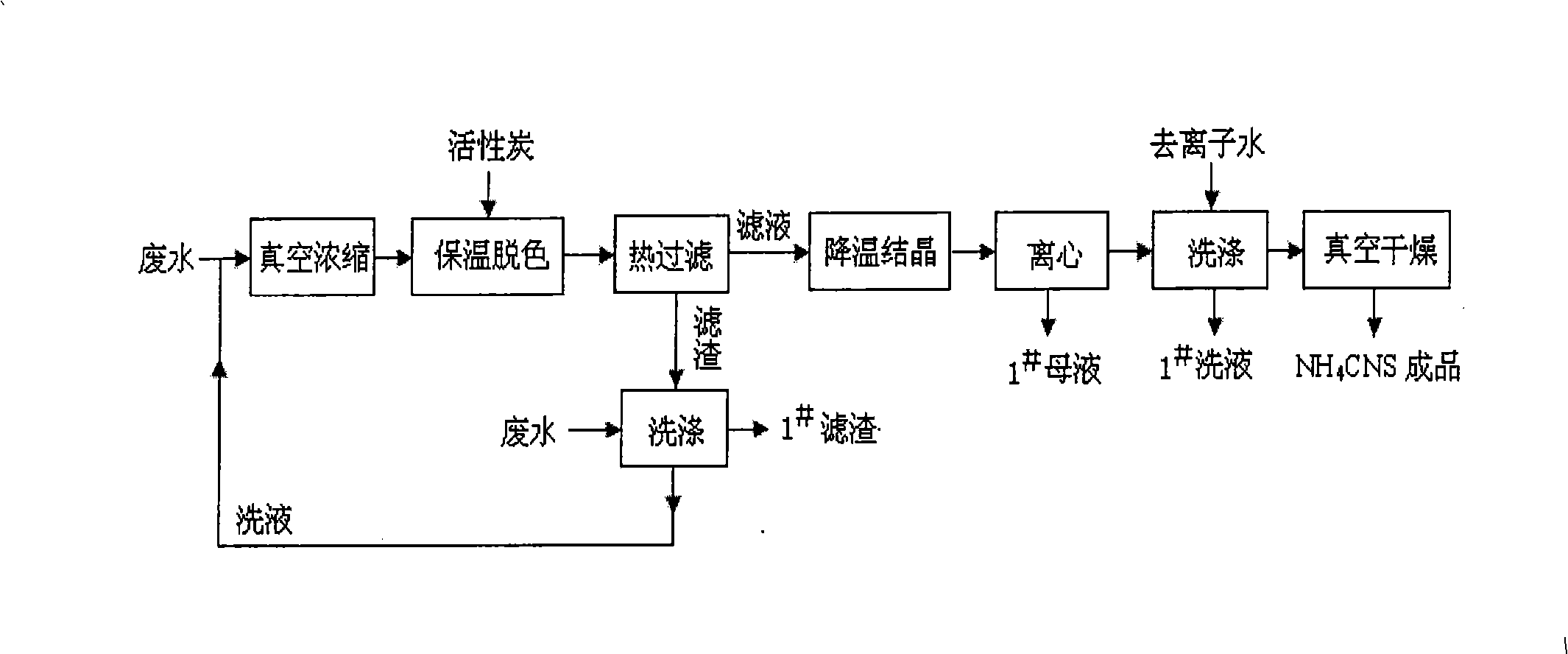

[0056] refer to figure 1 The process flow shown.

[0057] Coke oven gas desulfurization and decyanation wastewater 4000Kg (solid content 34.1%. Wherein NH 4 CNS content 19.8%, (NH 4 -) 2 S 2 o 3 content 12.1%), put it into a 5000-liter enamel kettle, heat it under vacuum conditions for dehydration and concentration, the concentration temperature is 82°C, remove 2200Kg of water, stop the heating, stop the vacuum, add 15Kg of activated carbon to decolorize at 75-80°C After 0.5h, perform hot filtration (use 75°C hot water to keep the filter warm). The obtained filter residue is washed with a small amount of waste water to obtain the washed 1 # Wet filter residue 26Kg ((NH 4 ) 2 SO 4 filter residue). The obtained clarified filtrate was stirred, cooled and crystallized, and when the temperature dropped to 18±2°C, it was kept at a constant temperature for 1h, and centrifugally filtered with a centrifuge to obtain 1 # The amount of mother liquor is about 1080L (of which, N...

Embodiment 2

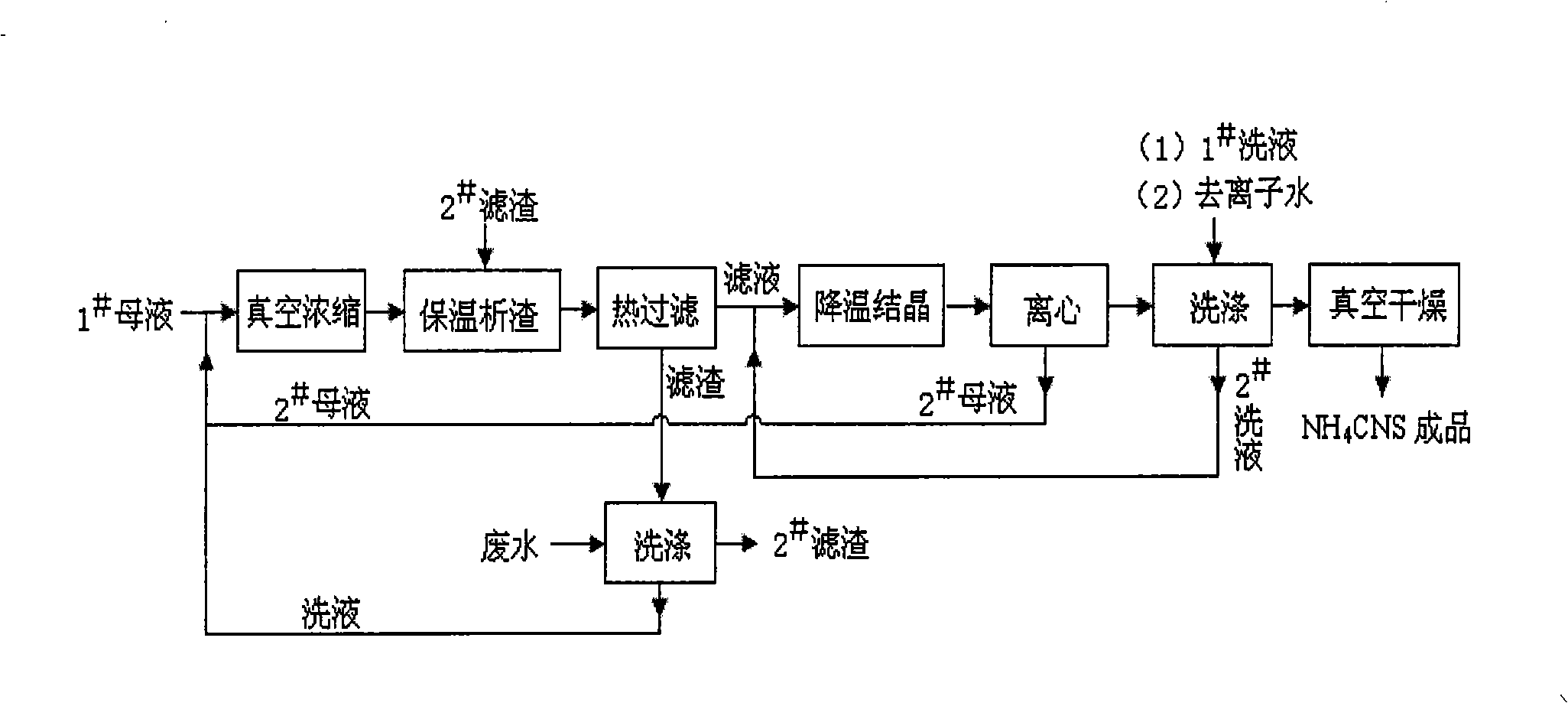

[0059] refer to figure 2 The process flow shown.

[0060] 2000kg is concentrated through embodiment 1 method, crystallization is separated NH 4 1 of CNS products # Mother liquor and 2 circulating in the system # Mixed solution of mother liquor (solid content 65.1%, where NH 4 CNS content 27.3%, (NH 4 ) 2 S 2 o 3 content 34.6%), put it into a 3000-liter enamel kettle, heat it with steam, and carry out dehydration and concentration under vacuum. When the temperature dropped to 53°C, add 10Kg2 # Filter residue (the first batch of available industry (NH 4 ) 2 S 2 o 3 ), keep stirring at a temperature of 49-55°C for 2h to complete the slagging. Then carry out hot filtration (use 53 ℃ of hot water to filter to keep warm), and wash filter residue with a small amount of 50 ℃ of waste water, obtain 2 # Filter residue 507Kg ((NH 4 ) 2 S 2 o 3 Filter residue, (NH 4 ) 2 S 2 o 3 Content 72.6%, NH 4 CNS content 6.2%, water content 10.1%, etc.) and clear filtrate. Wi...

Embodiment 3

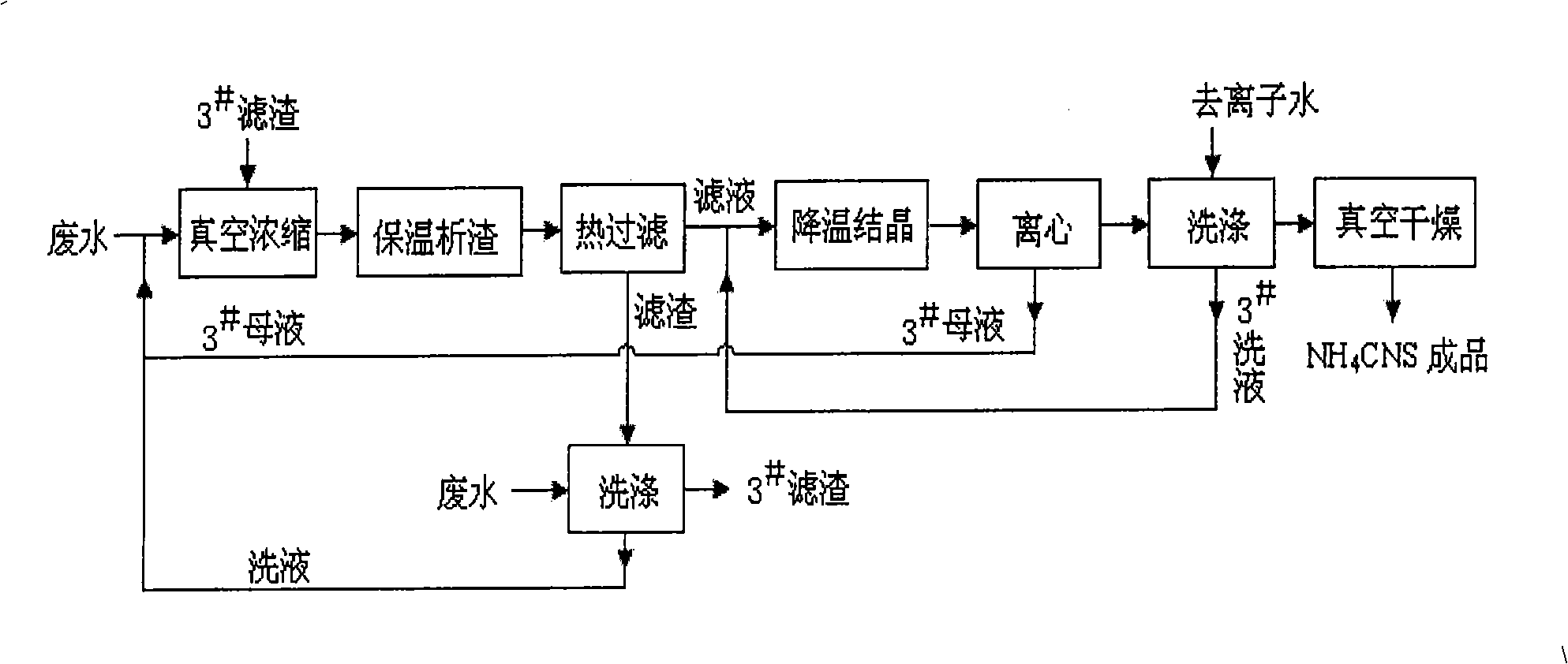

[0062] Refer to attached image 3 The process flow shown.

[0063] Coke oven gas desulfurization and decyanation wastewater 2000Kg (solid content 38.6%, of which NH 4 CNS content 15.2%, (NH 4 ) 2 S 2 o 3 Content 16.4%) and 3 circulating in the system # Mother liquor 1000Kg (solid content 67.3%, of which NH 4 CNS content 25.2%, (NH 4 ) 2 S 2 o 3 content 35.3%) into a 3000-liter enamel kettle, heated with steam, dehydrated in a vacuum state, the concentration temperature was 82°C, and 1050Kg of water was removed. After the concentration was completed, stop heating and vacuum, add 10Kg of activated carbon at 65-80°C Cool down after 0.5h of decolorization treatment, when the temperature drops to 55°C, add 15Kg 3 # Filter the residue for slag analysis, and keep stirring at a temperature of 48-53°C for 2 hours to complete the slag analysis. Carry out hot filtration then (with 52 ℃ of hot waters, filter is kept warm), and wash filter residue with a small amount of 50 ℃ of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com