System for desulfurization and magnesium sulfate heptahydrate co-production by using magnesium oxide

A technology of magnesium sulfate heptahydrate and magnesium oxide, applied in magnesium sulfate, chemical instruments and methods, gas treatment, etc., can solve the problems of desulfurization gypsum purity, compressive tensile strength, moisture content, natural gypsum competition, climate, soil, plants and other fields. Human health hazards, secondary pollution of desulfurized gypsum, etc., to achieve the effects of high product quality, easy separation, and low equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

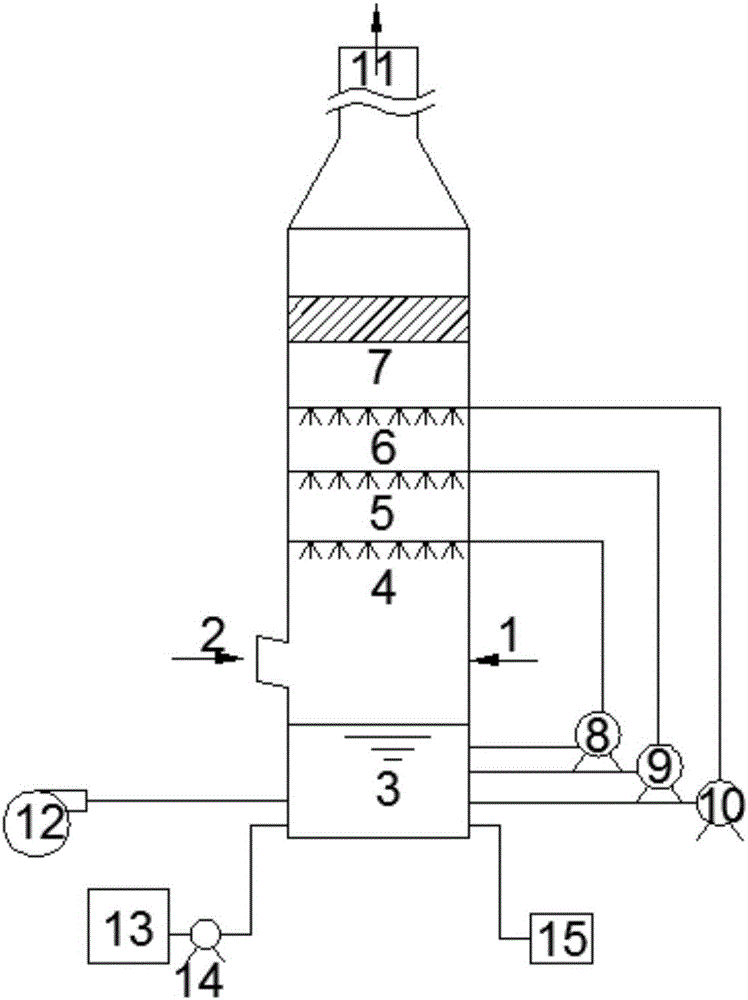

[0049] A kind of method of magnesium oxide desulfurization co-production magnesium sulfate heptahydrate of the present invention comprises the following steps:

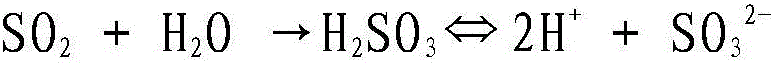

[0050] Step 1), the sulfur-containing flue gas enters from the lower part of the absorption tower, and is discharged from the flue gas outlet at the top of the absorption tower through the spray area of the absorption tower and the demisting area of the absorption tower in turn; the slurry sprayed by the spray head and the countercurrent flue gas Gas contact, the sulfur dioxide in the flue gas is absorbed by the slurry to form an absorption slurry;

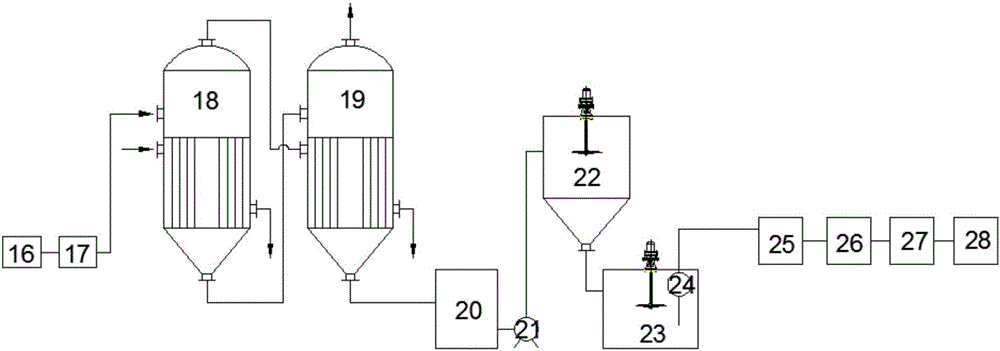

[0051] Step 2), when the density of the absorbed slurry reaches 1150kg / m 3 Part of the slurry is discharged from time to time, and the discharged slurry is processed by a plate and frame filter press. After the filtered clear liquid enters the evaporator, the evaporated liquid is obtained, and then the evaporated liquid is pumped into the cooling crystallizer; the eva...

Embodiment 2

[0054] A kind of method of magnesium oxide desulfurization co-production magnesium sulfate heptahydrate of the present invention comprises the following steps:

[0055] Step 1), the sulfur-containing flue gas enters from the lower part of the absorption tower, and is discharged from the flue gas outlet at the top of the absorption tower through the spray area of the absorption tower and the demisting area of the absorption tower in turn; the slurry sprayed by the spray head and the countercurrent flue gas Gas contact, the sulfur dioxide in the flue gas is absorbed by the slurry to form an absorption slurry;

[0056] Step 2), when the density of the absorbed slurry reaches 1200kg / m 3 Part of the slurry is discharged from time to time, and the discharged slurry is processed by a plate and frame filter press. After the filtered clear liquid enters the evaporator, the evaporated liquid is obtained, and then the evaporated liquid is pumped into the cooling crystallizer; the eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com