Production method of ore brine crystal salt

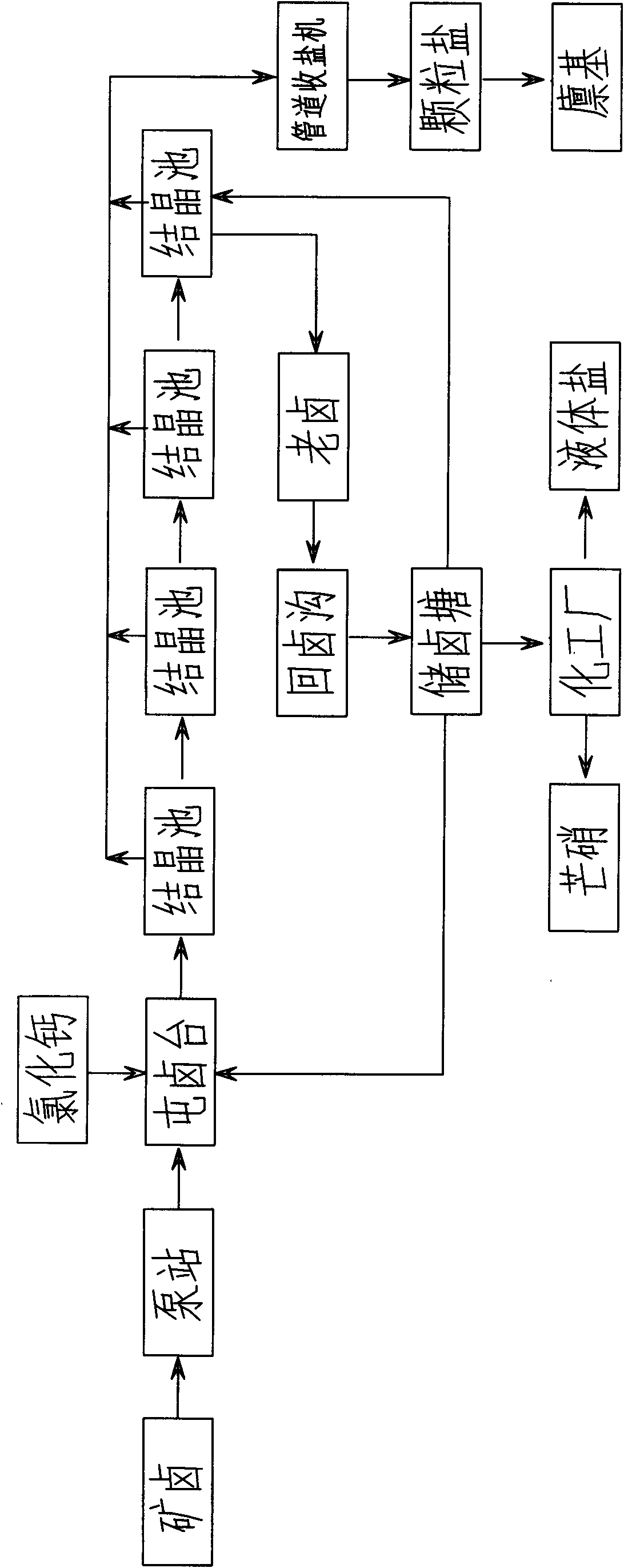

A production method and crystal technology, which are applied in the field of salt production, can solve the problems of large area of sea salt and high energy consumption of mineral salt, and achieve the effects of less impurity ions, low energy consumption and excellent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

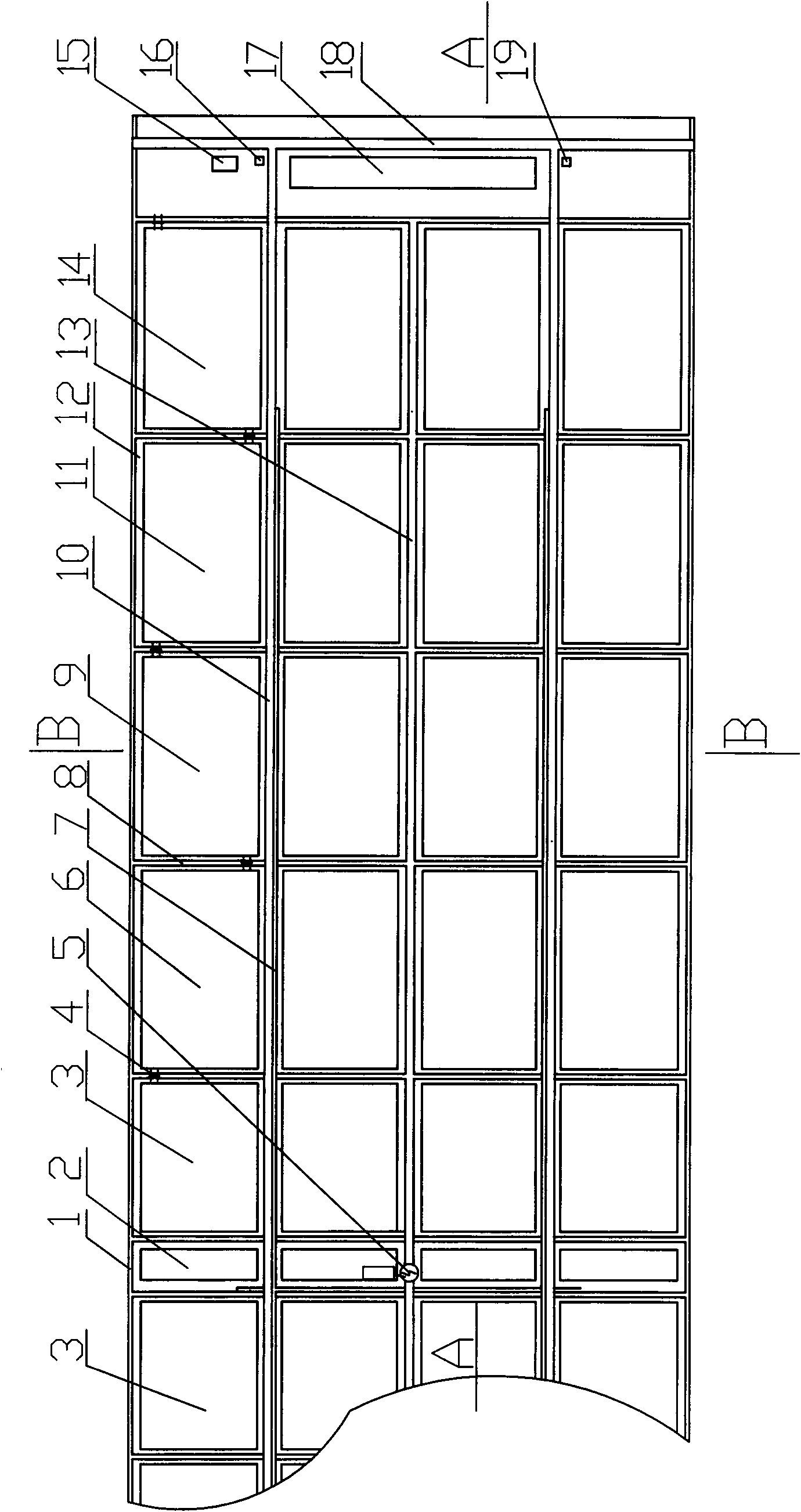

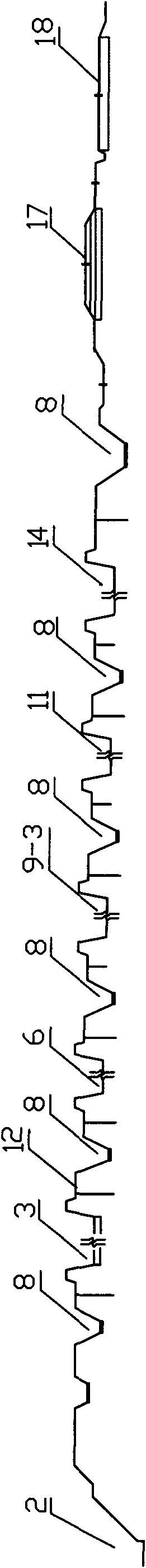

[0020] A production method of bittern crystalline salt, using bittern as raw bittern, wind and sun as energy source, beach pond as crystallization pool, bittern crystalline salt, after the bittern is mined, the laid pipeline passes through the pumping station After metering, divide and store brine platform 3, pour into crystallization tank 6,9 (9-1,9-2,9-3,9-4), 11,14 by storage brine platform 3 again, pass wind in crystallization tank Blow the sun to evaporate and crystallize; control the concentration and depth of brine in the crystallization pool, add or replace new brine in a timely manner, grasp the depth of crystallized salt and market demand, discharge brine and collect salt in time, and recycle old brine.

[0021] The plane setting of the field area is divided into several units, and each unit is equipped with 8 combined plots, which are divided into four rows and two columns. There are four brine storage ponds 2 between the two columns. There are drainage ditches 7 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com