System and technology for concentration and crystallization treatment of high-salinity water

A concentrated crystallization and treatment system technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as crystal fragmentation, blockage of pipelines and heat exchangers, difficulty in crystal dehydration, etc., and achieve easy separation , to ensure the effect of completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

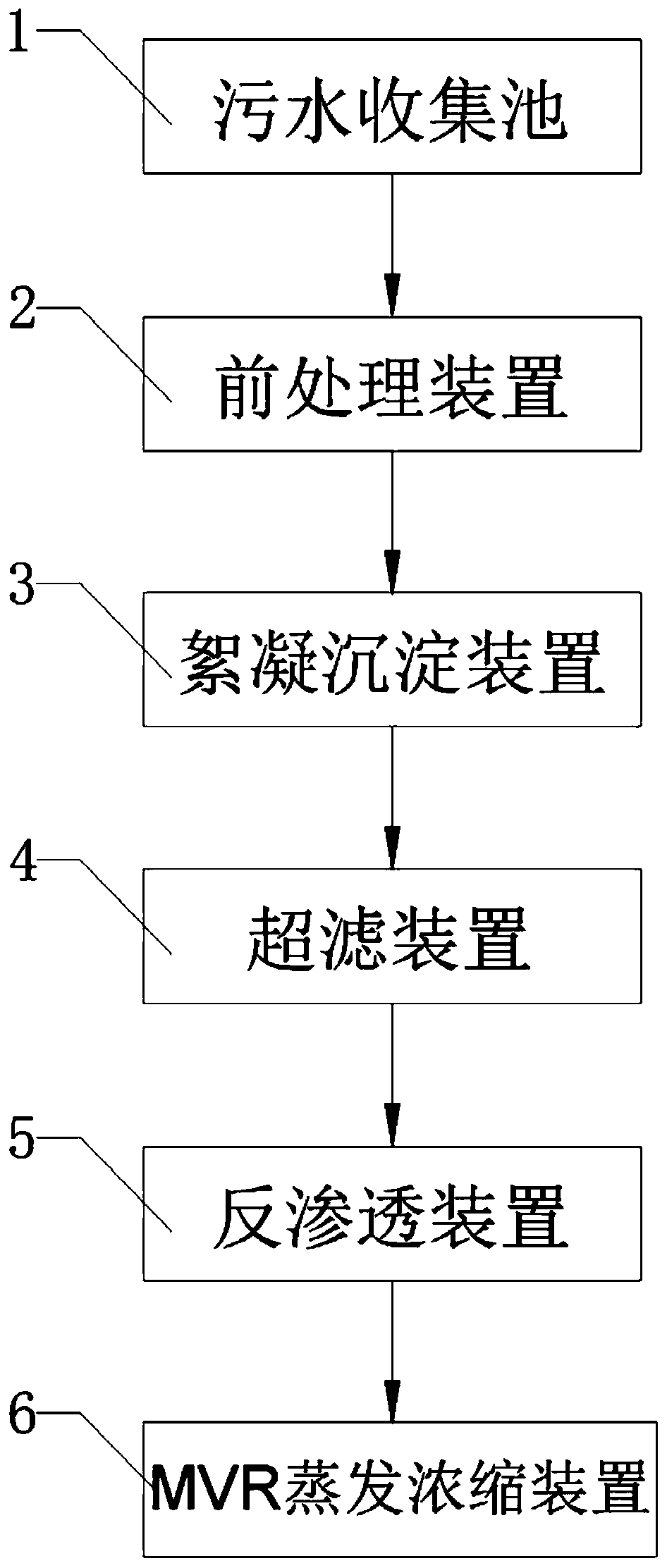

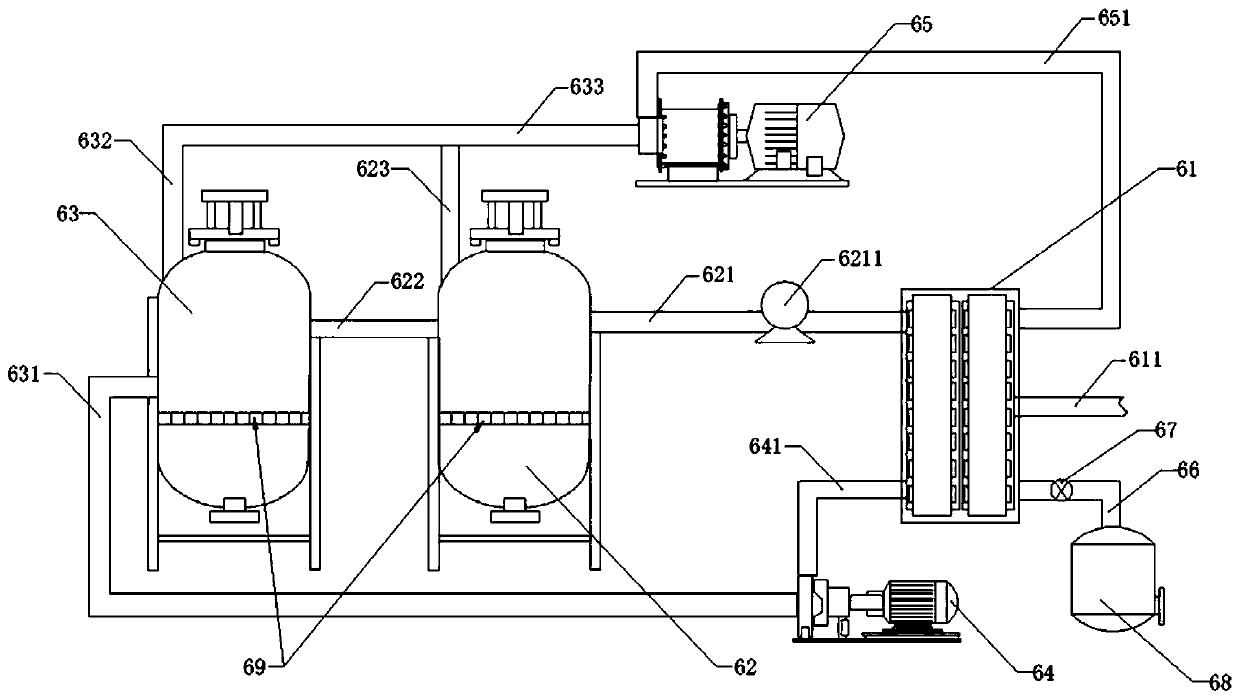

[0037] See attached Figure 1-2 , a high brine concentration and crystallization treatment system, which sequentially includes a sewage collection tank 1, a pretreatment device 2, a flocculation sedimentation device 3, an ultrafiltration device 4, a reverse osmosis device 5, and an MVR evaporation concentration device 6 according to the order of use. Evaporation concentration device 6 comprises plate heat exchanger 61, the first precipitation crystallization tank 62, the second precipitation crystallization tank 63 and material liquid circulation pump 64 successively according to the order of treatment and use, the steam outlet port of the first precipitation crystallization tank 62, the first precipitation crystallization tank 62 The steam outlet ends of the two precipitation crystallization tanks 63 are all communicated with the plate heat exchanger 61 through the steam compressor 65; It communicates with the output end of the reverse osmosis device 5 .

[0038] The plate h...

Embodiment 2

[0046] A treatment process using the above-mentioned high brine concentration crystallization treatment system, comprising the steps of:

[0047] 1 Collect the factory sewage into the sewage collection tank 1, carry out oil and slag removal treatment through the pre-treatment device 2, and then carry out impurity removal treatment through the flocculation and sedimentation device 3, the ultrafiltration device 4, and the reverse osmosis device 5;

[0048] 2. The feed liquid after the impurity removal treatment in step 1 enters the plate heat exchanger 61 through the feed end of the plate heat exchanger 61 to heat up and heat up, and then flows into the first precipitation crystallization tank 62 and the second precipitation crystallization tank 63 for precipitation and separation , the separated feed liquid is pumped into the plate heat exchanger 61 through the feed liquid circulation pump 64 to heat up again, and carry out circulation precipitation separation;

[0049] At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com