A method for recycling washing water and by-product magnesium ammonium fertilizer in the production process of carbonization magnesia

A technology of by-product magnesium ammonium fertilizer and production process, which is applied in the field of waste water recycling and by-product ammonium sulfate fertilizer, can solve the problems of activated sludge failure in sewage treatment system, ammonia nitrogen wastewater pollution, water swelling, etc., and achieve easy filtration, Low water content, the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

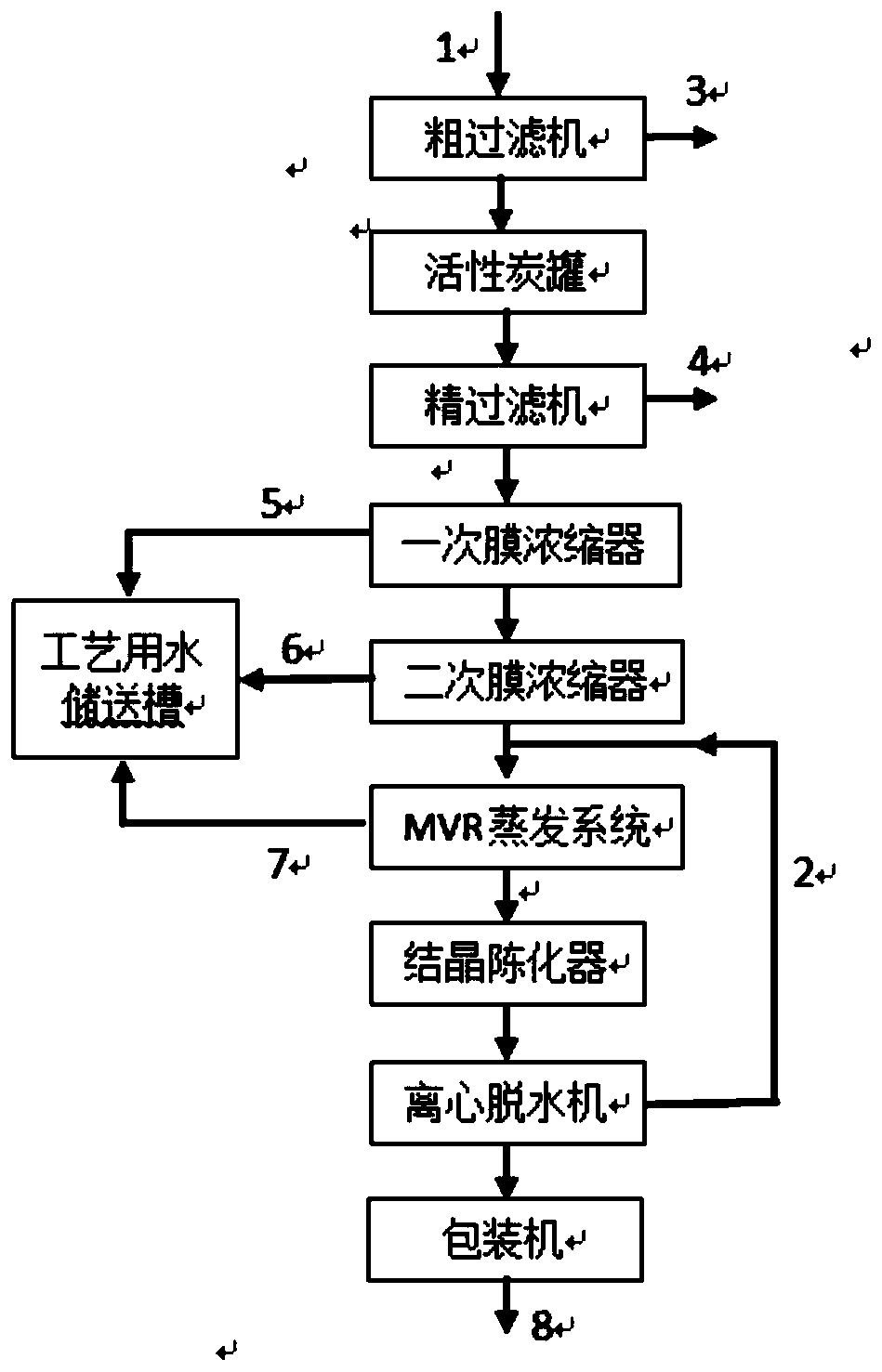

Method used

Image

Examples

Embodiment 1

[0037] Example 1

[0038] The ammonium ion is 3.20g / L, the magnesium ion is 0.61g / L and the sulfate radical is 11.0g / L, and the flow rate is 50m3 The washing water (1) of / h is pressurized to 0.6MPa, enters the liquid-solid cyclone separator group with the flow velocity of 35m / s, and the liquid-solid cyclone separator group removes the larger solid matter contained in the washing water Particles are separated. The washing water from the liquid-solid cyclone separator group first enters the volume of 2.0m 3 The activated carbon adsorption tank further separates the impurities in it, and then pressurizes to 0.68MPa and then enters the filter area with a filter area of 40m 2 The plate and frame filter further filters out the fine solid particles to obtain the fine filtrate.

[0039] The fine filtrate is pumped into after pressurized to a processing capacity of 60m 3 / h salt water volume of primary membrane concentration reverse osmosis membrane water purification device, get...

Embodiment 2

[0044] The ammonium ion is 2.80g / L, the magnesium ion is 0.58g / L and the sulfate radical is 9.8g / L, and the flow rate is 60m 3 / h washing water is pressurized to 0.5MPa, and enters the liquid-solid cyclone separator group at a flow rate of 28m / s, and the liquid-solid cyclone separator group separates the larger solid matter particles contained in the washing water. The washing water from the liquid-solid cyclone separator group first enters the volume of 2.0m 3 The activated carbon adsorption tank further separates the impurities in it, and then pressurizes to 0.55MPa to enter the filter area with a filter area of 40m 2 The plate and frame filter further filters out the fine solid particles to obtain the fine filtrate.

[0045] After the fine filtrate is pressurized, it is pumped to a processing capacity of 80m 3 / h salt water volume of primary membrane concentration reverse osmosis membrane water purification device, get 36.3m 3 / h primary membrane separation of clean wa...

Embodiment 3

[0050] The washing water contains 3.80g / L of ammonium ions, 0.77g / L of magnesium ions and 13.2g / L of sulfate radicals, and the flow rate is 45m 3 The washing water / h is pressurized to 0.6MPa, and enters the liquid-solid cyclone separator group at a flow rate of 23m / s, and the liquid-solid cyclone separator group removes the larger solids contained in the washing water Particles of matter are separated. The washing water from the liquid-solid cyclone separator group first enters the volume of 2.0m 3 The activated carbon adsorption tank further separates the impurities in it, and then pressurizes to 0.65MPa to enter the filter area with a filter area of 40m 2 The plate and frame filter further filters out the fine solid particles to obtain the fine filtrate.

[0051] Pressurize the fine filtrate into a 60m 3 / h salt water volume of primary membrane concentration reverse osmosis membrane water purification device, get 26.9m 3 / h primary membrane separation of clean water an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com