Preparation method for high-purity baicalin

A baicalin, high-purity technology, applied in the field of preparation of high-purity baicalin, can solve the problems of complex solvent residue removal process, low resin adsorption efficiency, yield and purity impact, etc., to achieve clinical application and convenience for follow-up The effect of treatment and avoiding secondary hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation of high-purity baicalin

[0044]1) Take 100.0 g of crude baicalin (content 83%), add it to a mixed solvent of 110 g of dimethyl sulfoxide (DMSO) and 200 g of methanol, stir and heat to 60° C. to dissolve, and obtain a baicalin solution;

[0045] 2) filter to remove insoluble impurities;

[0046] 3) Add 1000 g of methanol to the filtrate.

[0047] 4) Stir and heat to reflux to generate a yellow precipitate, and keep warm for 1 hour;

[0048] 5) cooling, filtering, washing with methanol, and drying to obtain 75.2 g of the product.

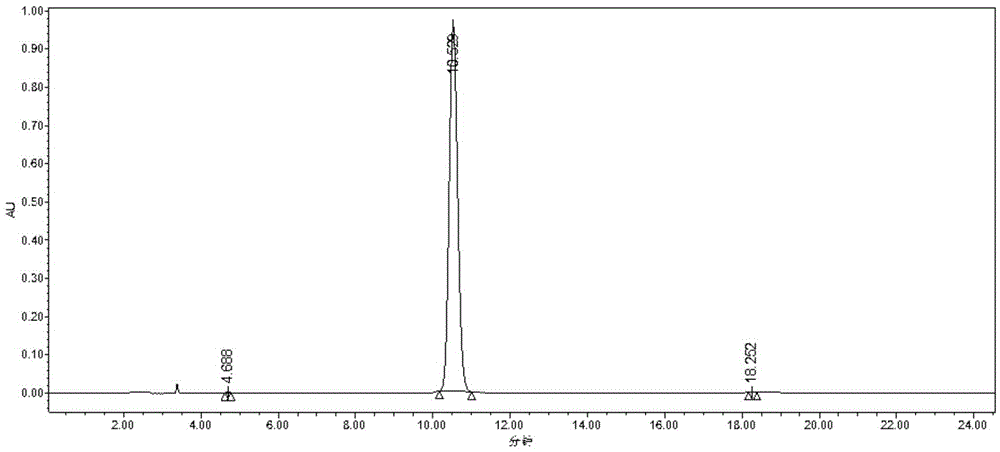

[0049] The HPLC determination method of baicalin is: isocratic elution, detection wavelength 280nm, column temperature 25°C, mobile phase: methanol-0.2% phosphoric acid aqueous solution (47:53), octadecylsilane bonded silica gel as filler. The HPLC determination method is detected according to the baicalin standard (standard number WS-10001-(HD-0989)-2002), which is sourced from "National Standards for Local ...

Embodiment 2

[0051] Embodiment two: the preparation of high-purity baicalin

[0052] 1) Take 100.0 g of crude baicalin (content 83%), add it into a mixed solvent of 100 g of dimethyl sulfoxide (DMSO) and 50 g of ethanol, stir and heat to 70° C. to dissolve, and obtain a baicalin solution;

[0053] 2) filter to remove insoluble impurities;

[0054] 3) Add 400 g of ethanol to the filtrate.

[0055] 4) Stir and heat to reflux to generate a yellow precipitate and keep it warm for 1.5 hours;

[0056] 5) Cool, filter, wash with methanol, and dry to obtain 78.5 g of the product. .

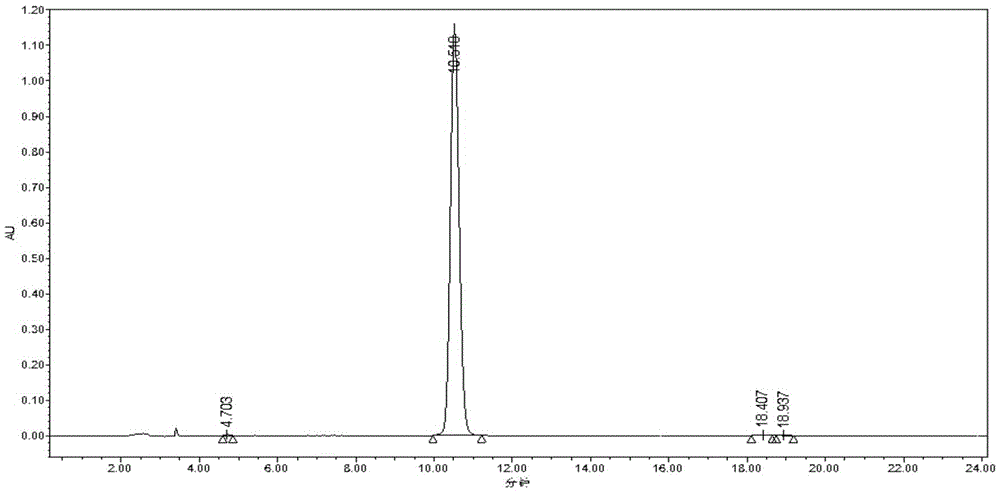

[0057] The assay method of baicalin refers to Example 1, and its liquid phase spectrum is shown in figure 2 , HPLC assay content: 98.7%.

Embodiment 3

[0058] Embodiment three: the preparation of high-purity baicalin

[0059] 1) Take 100.0 g of crude baicalin (content 83%), add it to a mixed solvent of 250 g of dimethyl sulfoxide (DMSO) and 150 g of isopropanol, stir and heat to 90° C. to dissolve, and obtain a baicalin solution;

[0060] 2) filter to remove insoluble impurities;

[0061] 3) Add isopropanol 800g again in the filtrate.

[0062] 4) Stir and heat to reflux to generate a yellow precipitate and keep it warm for 0.5 hours;

[0063] 5) Cool, filter, wash with ethanol, and dry to obtain 78.9 g of the product.

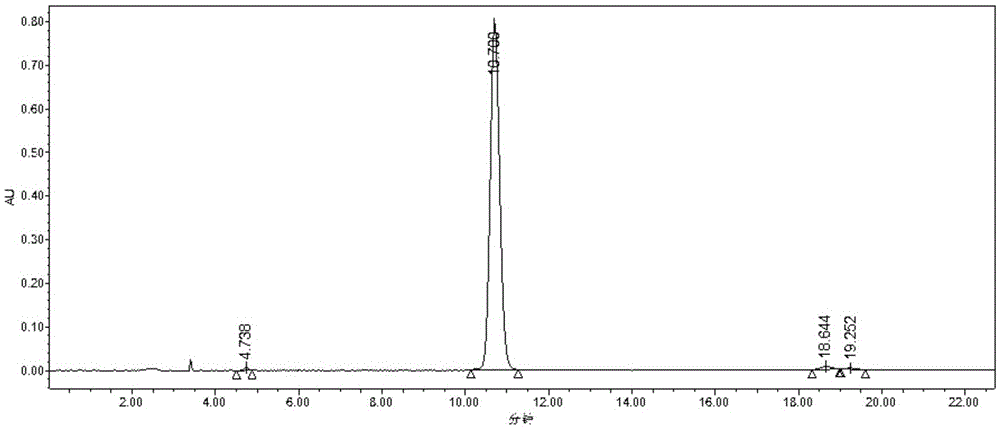

[0064] The assay method of baicalin refers to Example 1, and its liquid phase spectrum is shown in image 3 , HPLC assay content: 97.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com