Structure and making method of thin film transistor

A technology of thin-film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., and can solve the problems of slow electron movement and affecting the performance of thin-film transistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

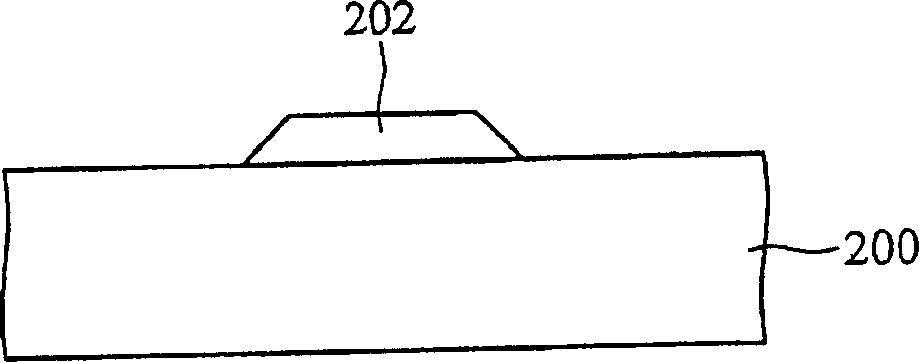

[0028] First, if Figure 2A As shown, a gate layer is formed on a substrate 200 by a deposition method such as sputtering, the substrate 200 is preferably a glass substrate, and the gate layer is preferably a metal layer, which can be made of tantalum (Ta) , Tungsten (W), Molybdenum (Mo), Titanium (Ti), Chromium (Cr), Aluminum (Al) or their alloys. Afterwards, the gate layer is patterned by a general photolithography method to form a gate 202 on the substrate 200 .

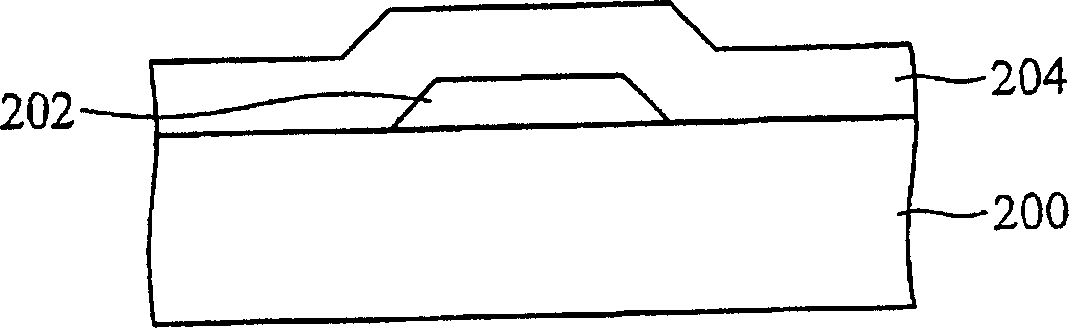

[0029] Next, if Figure 2B As shown, with a deposition method, such as chemical vapor deposition (chemical vapor deposition), a gate dielectric layer 204 is formed to cover the gate 202 and the substrate 200, and the gate dielectric layer 204 is preferably composed of the following molecules Groups: oxides of tantalum, oxides of tungsten, oxides of molybdenum, oxides of titanium, oxides of chromium, oxides of aluminum, oxides of silicon, nitrides of silicon, oxynitrides of silicon, and combinations thereof .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com