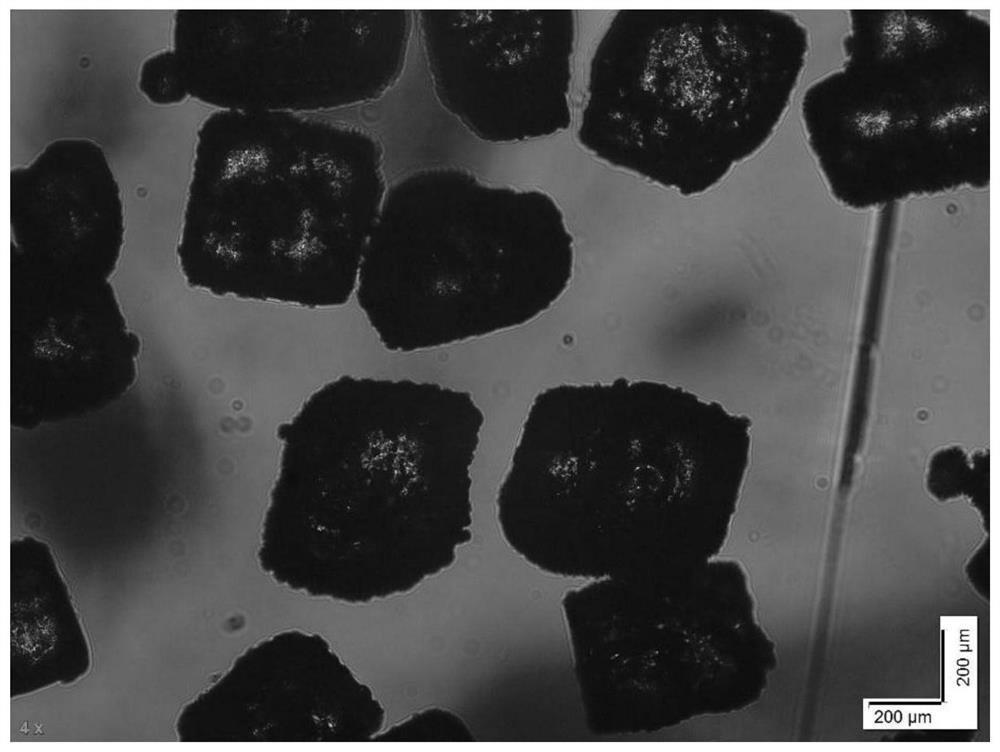

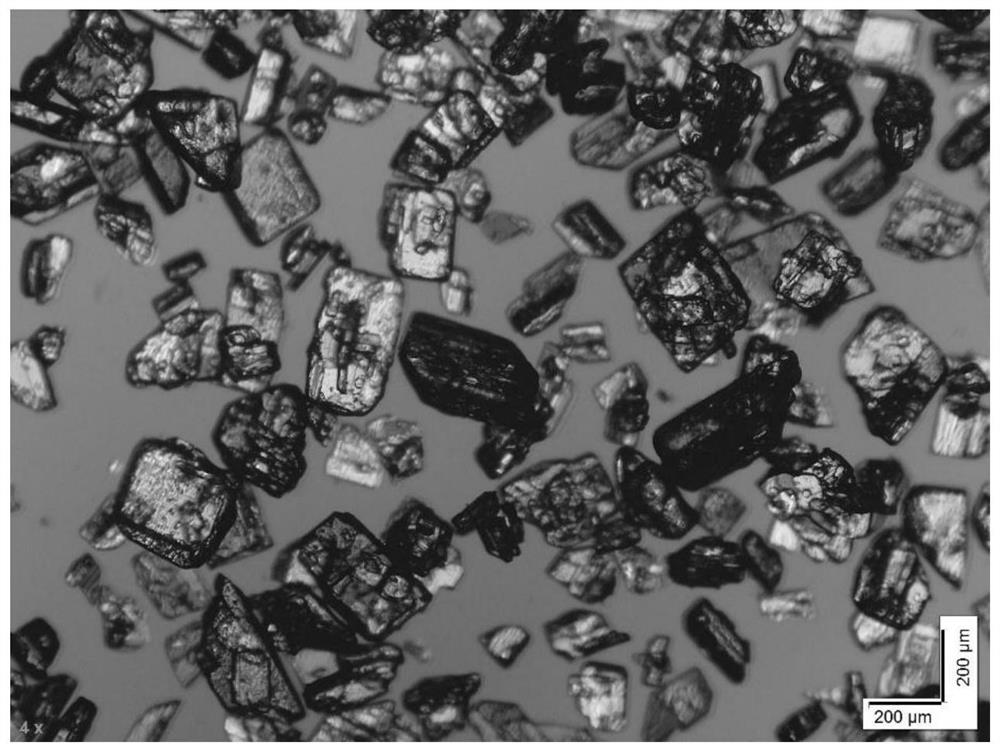

Preparation method of ammonium persulfate crystal

A technology of ammonium persulfate and ammonium sulfate, applied in the direction of peroxyhydrate/peroxyacid, etc., can solve the problems of high supersaturation, uneven nucleation particle size, a large number of small crystals, etc., and achieve uniform particle size and particle size distribution of finished products. The effect of uniform and large crystal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a kind of preparation method of ammonium persulfate crystallization, and concrete steps are as follows:

[0042] (1) The ammonium persulfate electrolyte is returned to the feeding kettle, where a batching is completed, specifically, ammonium sulfate is put into to adjust the composition of the mother liquor, so that the ammonium persulfate is more likely to crystallize and separate out (salting out). The mass concentration ratio of ammonium persulfate and ammonium sulfate is about 1:2.5. During the batching process, feed while stirring to fully dissolve the ammonium sulfate. This solution flows into the batching kettle, flows into the feeding tank through the overflow pipe, passes through the ammonia until the pH value is below 7, and obtains the mother liquor. Turn on the liquid injection pump. The mother liquor is poured into the filter for crystallization, and the temperature of the mother liquor is 30°C;

[0043] (2) Control the crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com