A kind of cigs-based thin film solar cell and preparation method thereof

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as battery performance degradation, increase in battery series resistance, affecting film ohmic contact, etc., to reduce compounding, improve short-circuit current, and achieve The effect of large-area uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

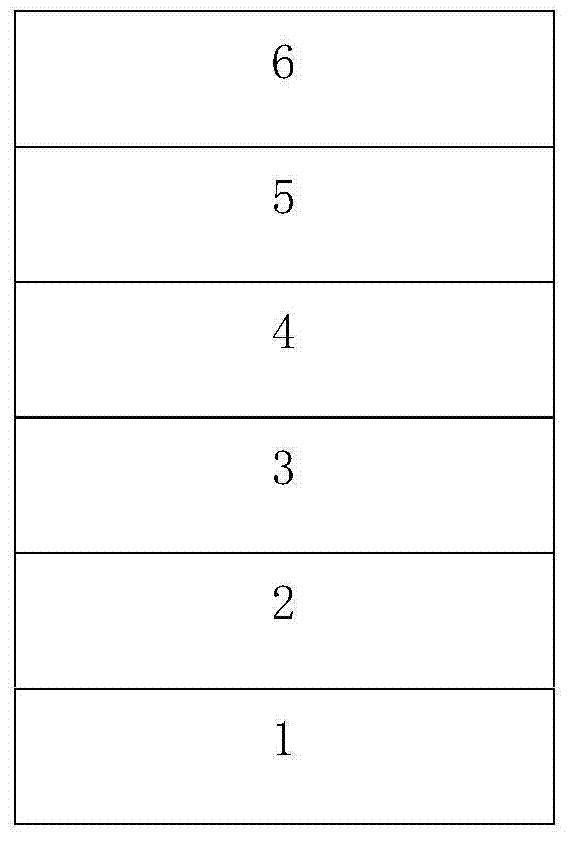

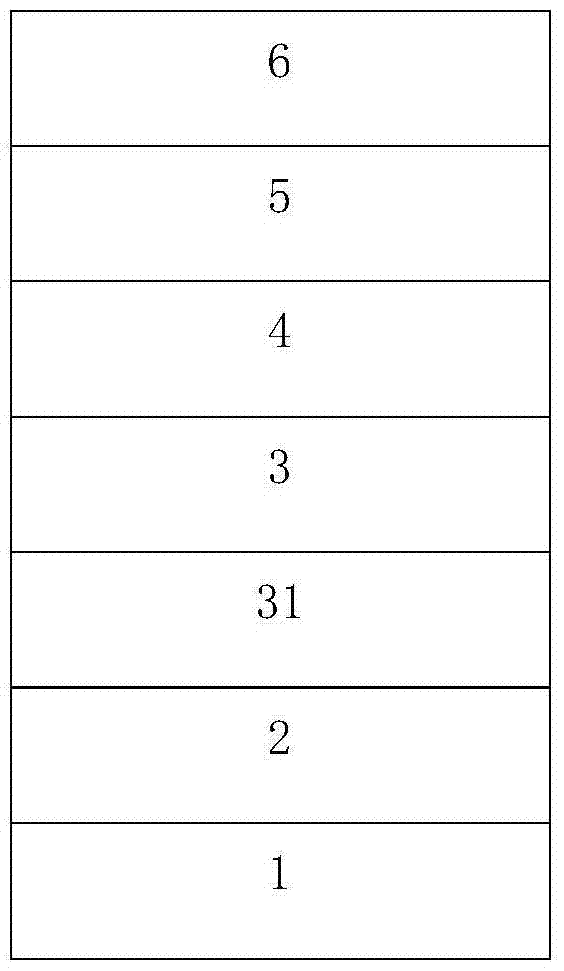

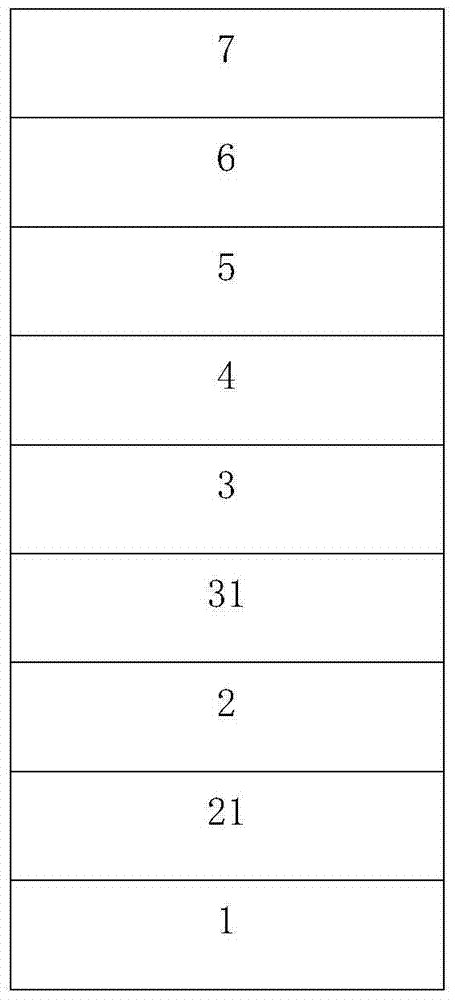

[0029] A metal molybdenum electrode layer of 500nm is deposited by magnetron sputtering on the substrate of soda-lime glass; then a 30nm antimony-gallium alloy film layer is deposited by magnetron sputtering on the molybdenum back electrode layer, and the antimony-gallium alloy film layer contains 50at % antimony; then form a 2.0um thick p-type copper indium gallium selenide film layer with a chalcopyrite structure on the antimony gallium alloy film layer, and the heat treatment temperature for forming the p-type copper indium gallium selenide film layer is 520 ℃; Then adopt the chemical bath (CBD) method to deposit the CdS film layer of 45nm on the p-type copper indium gallium selenide film layer as the buffer layer; adopt magnetron sputtering to deposit the intrinsic ZnO film layer of 40nm on the buffer layer; A 600nm AZO film was deposited on the ZnO film by magnetron sputtering.

[0030] After the p-type copper indium gallium selenide film layer is formed, the soda lime gl...

Embodiment 2

[0032]A 500nm metal molybdenum electrode layer is deposited by magnetron sputtering on the substrate of soda-lime glass; then a 100nm antimony-gallium alloy film layer is deposited on the molybdenum back electrode layer by magnetron sputtering, and the antimony-gallium alloy film layer contains 65at % antimony; then form a 2.0um thick p-type copper indium gallium selenide film layer with a chalcopyrite structure on the antimony gallium alloy film layer, and the heat treatment temperature for forming the p-type copper indium gallium selenide film layer is 520 ℃; Then adopt the chemical bath (CBD) method to deposit the CdS film layer of 45nm on the p-type copper indium gallium selenide film layer as the buffer layer; adopt magnetron sputtering to deposit the intrinsic ZnO film layer of 40nm on the buffer layer; A 600nm AZO film was deposited on the ZnO film by magnetron sputtering.

[0033] After the p-type copper indium gallium selenide film layer is formed, the soda lime glass...

Embodiment 3

[0035] A 500nm metal molybdenum electrode layer is deposited by magnetron sputtering on the substrate of soda-lime glass; then a 40nm silver-antimony alloy film layer is deposited by magnetron sputtering on the molybdenum back electrode layer, and the silver-antimony alloy film layer contains 60at % silver; then form a 2.1um thick p-type copper indium gallium selenide film layer with a chalcopyrite structure on the silver antimony alloy film layer, and the heat treatment temperature for forming the p-type copper indium gallium selenide film layer is 520 ℃; Then adopt the chemical bath (CBD) method to deposit the CdS film layer of 40nm on the p-type copper indium gallium selenide film layer as the buffer layer; Adopt magnetron sputtering to deposit the intrinsic ZnO film layer of 50nm on the buffer layer; On the ZnO film layer, a 800nm AZO film layer was deposited by magnetron sputtering.

[0036] After the p-type copper indium gallium selenide film layer is formed, the soda ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com