Method and device for crystallizing and separating dicyandiamide

A technology of crystallization separation and dicyandiamide, applied in crystallization separation, separation method, heat exchange cooling crystallization and other directions, can solve the problems of environmental pollution, complex process, low crystal purity, etc., to improve the collection efficiency and product yield, The effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

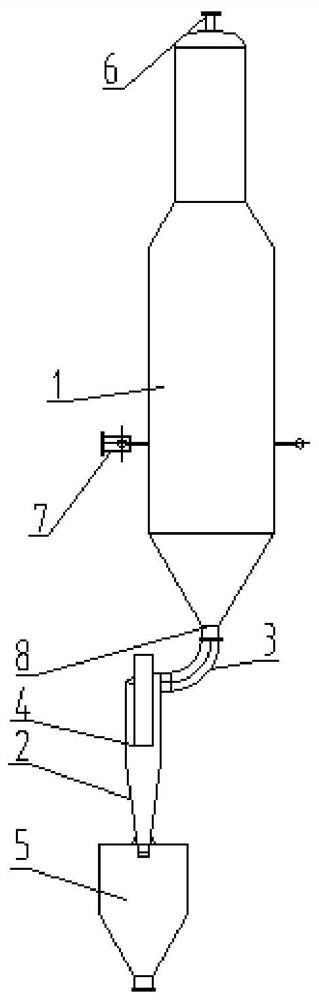

[0036] A dicyandiamide crystallization separation method, the method is to use the above-mentioned device to utilize the dicyandiamide process hot gas produced by the gas phase polymerization of cyandiamide, its main components include at least ammonia, CO2, dicyandiamide and other media, the temperature is 550 ° C, The pressure is 0.6Mpa, the process hot gas inlet 6 set on the top of the crystallizer 1 enters the crystallizer 1, and the process cold air enters the interior of the crystallizer 1 from the process cold air inlet 7. The medium of the process cold air is a mixture of ammonia and CO2. The temperature of the cold air is 150°C, and the pressure is 0.6Mpa. The process cold air is mixed with the process hot air, and the temperature after mixing is 200°C, and a gas-solid mixture is formed, which flows out from the process gas outlet provided at the bottom of the crystallizer 1.

[0037] The medium flowing out from the process gas outlet at the bottom of the crystallizer ...

Embodiment 2

[0040] A dicyandiamide crystallization separation method, the method is to use the dicyandiamide process hot gas produced by the gas phase polymerization of cyandiamide, its main components include at least ammonia, CO2, dicyandiamide and other media, the temperature is 250 ° C, the pressure is 0.3 Mpa, the process hot gas inlet 6 set on the top of the crystallizer 1 enters the crystallizer 1, and the process cold air enters the crystallizer 1 from the process cold air inlet 7. The medium of the process cold air is CO2 gas, and the temperature of the process cold air is 100 ° C. The pressure is 0.6Mpa. The process cold air is mixed with the process hot air, and the temperature after mixing is 150°C, and a gas-solid mixture is formed, which flows out from the process gas outlet provided at the bottom of the crystallizer 1 .

[0041] The medium flowing out from the process gas outlet at the bottom of the crystallizer 1 is a gas-solid two-phase, wherein the solid phase is a solid ...

Embodiment 3

[0044] A dicyandiamide crystallization separation method, the method is to use the dicyandiamide process hot gas produced by the gas phase polymerization of cyandiamide, its main components include at least ammonia, CO2, dicyandiamide and other media, the temperature is 350 ° C, the pressure is 0.4 Mpa, the process hot gas inlet 6 set on the top of the crystallizer 1 enters the crystallizer 1, and the process cold air enters the crystallizer 1 from the process cold air inlet 7. The medium of the process cold air is NH3 gas, and the temperature of the process cold air is 20 ° C. The pressure is 0.3Mpa. The process cold air is mixed with the process hot air, and the temperature after mixing is 80°C, and a gas-solid mixture is formed, which flows out from the process gas outlet provided at the bottom of the crystallizer 1 .

[0045]The medium flowing out from the process gas outlet at the bottom of the crystallizer 1 is a gas-solid two-phase, wherein the solid phase is a solid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com