Circulation-type crystallizer

A crystallizer and circulation technology, applied in the direction of solution crystallization, can solve the problems of short crystallization time, high water content, low energy consumption, etc., and achieve the effect of short crystallization time, large crystal particles and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

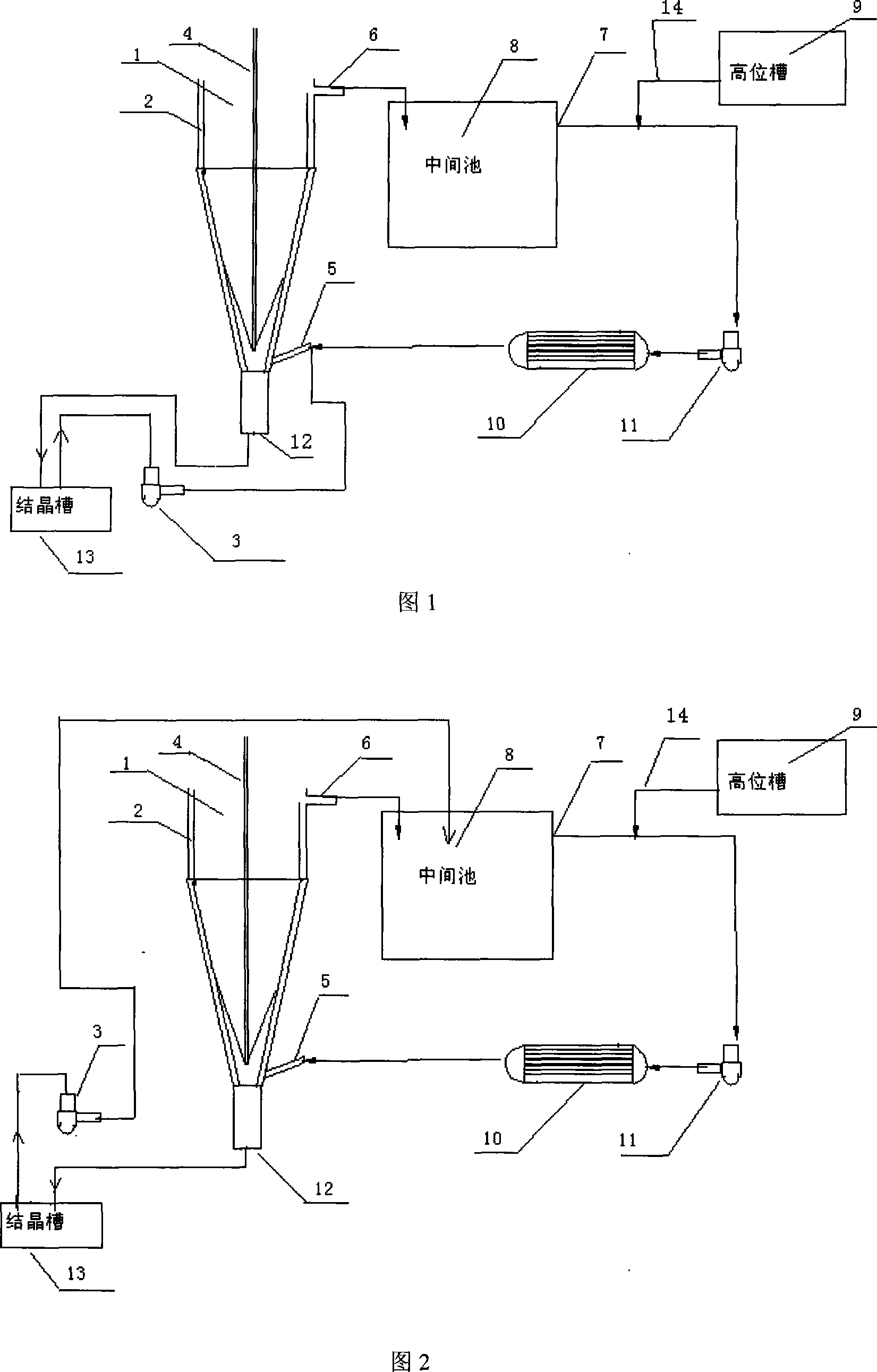

[0018] A circulating crystallizer, except that the mother liquor return tank pipeline communicates with the intermediate tank, the other structures are exactly the same as the first embodiment.

[0019] See attached picture 2:

[0020] During work, the initial crystallization solution is placed in the head tank 9, cooled by the condenser 10 when flowing through the circulation pipeline, and then sent into the crystallization tank 1, under the action of the stirring rod 4 in the crystallization tank 1, there is constantly A small amount of crystallization and mother liquor flow into the intermediate tank 8 from the liquid outlet 6, and the lower layer of the intermediate tank 8 gathers crystals, but the overflow port 7 continuously has the mother liquor flowing out and passing into the circulation pipeline. After a certain time interval, the crystallization solution is fully mixed in the crystallization tank 1, and more and more crystals are deposited at the bottom of the cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com