Method for recycling washing water and coproducing magnesium ammonium fertilizer during carbonization-process magnesium oxide production

A by-product magnesium ammonium fertilizer and production process technology, applied in the field of wastewater recycling and by-product ammonium sulfate magnesium fertilizer, can solve the problems of ammonia nitrogen wastewater pollution, activated sludge failure of sewage treatment system, water swelling, etc., and achieve low water content , easy to filter and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

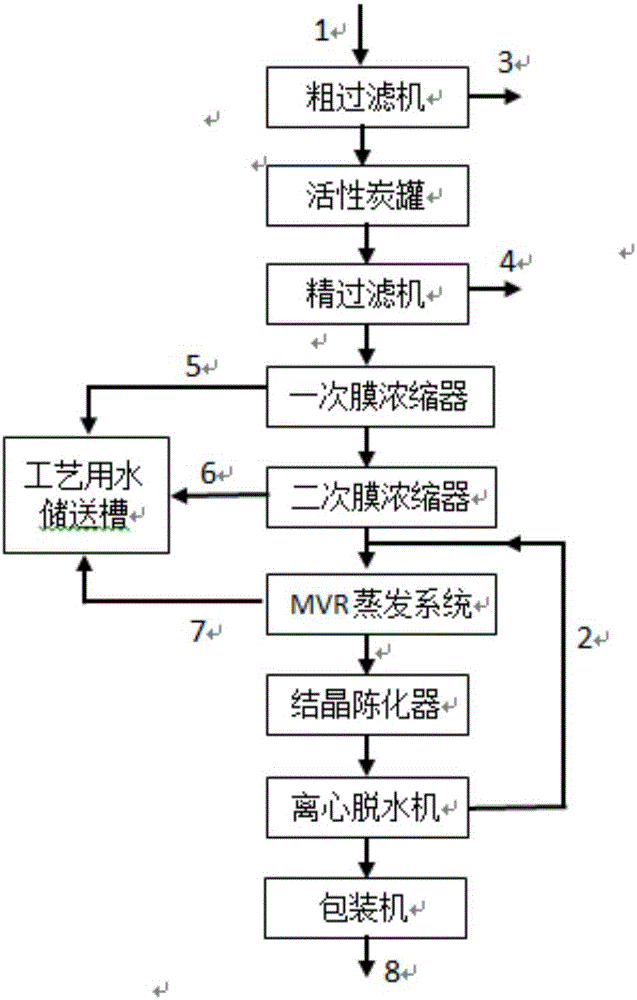

Image

Examples

Embodiment 1

[0037] Example 1

[0038] Set ammonium ion to 3.20g / L, magnesium ion to 0.61g / L and sulfate to 11.0g / L, and the flow rate is 50m 3 / h of washing water (1) is pressurized to 0.6MPa, and enters the liquid-solid hydrocyclone group at a flow rate of 35m / s, and the liquid-solid hydrocyclone group removes the solid substances with larger particle size in the washing water. The particles are separated. The washing water from the liquid-solid hydrocyclone group first enters the volume of 2.0m 3 The activated carbon adsorption tank further separates the impurities, and then pressurizes to 0.68MPa and enters the filter area of 40m 2 The plate and frame filter further filters out the fine solid particles to obtain a fine filtrate.

[0039] The fine filtrate is pressurized and then pumped to a processing capacity of 60m 3 / h salt water volume of the primary membrane concentration reverse osmosis membrane water purification device, 29.9m 3 / h Primary membrane separation of purified water and ...

Embodiment 2

[0044] Set ammonium ion to 2.80g / L, magnesium ion to 0.58g / L, and sulfate to 9.8g / L, and the flow rate is 60m 3 The washing water per hour is pressurized to 0.5 MPa and enters the liquid-solid hydrocyclone group at a flow rate of 28 m / s, and the liquid-solid hydrocyclone group separates the solid material particles with larger particle size contained in the washing water. The washing water from the liquid-solid hydrocyclone group first enters the volume of 2.0m 3 The activated carbon adsorption tank further separates the impurities, and then pressurizes to 0.55MPa to enter the filter area of 40m 2 The plate and frame filter further filters out the fine solid particles to obtain a fine filtrate.

[0045] Press the said fine filtrate and drive it to a processing capacity of 80m 3 / h salt water volume of the primary membrane concentration reverse osmosis membrane water purification device, 36.3m 3 / h Primary membrane separation of purified water and 23.7m 3 / h Medium-strength brine ...

Embodiment 3

[0050] The washing water contains ammonium ions at 3.80g / L, magnesium ions at 0.77g / L, and sulfate ions at 13.2g / L, and the flow rate is 45m 3 / h of washing water is pressurized to 0.6MPa and enters the liquid-solid hydrocyclone group at a flow rate of 23m / s. The liquid-solid hydrocyclone group removes the solids with larger particle size in the washing water. The material particles are separated. The washing water from the liquid-solid hydrocyclone group first enters the volume of 2.0m 3 The activated carbon adsorption tank further separates the impurities, and then pressurizes to 0.65MPa to enter the filter area of 40m 2 The plate and frame filter further filters out the fine solid particles to obtain a fine filtrate.

[0051] After pressurizing the described fine filtrate, it is injected to a processing capacity of 60m 3 / h salt water volume of the primary membrane concentration reverse osmosis membrane water purification device, 26.9m 3 / h Primary membrane separation of puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com