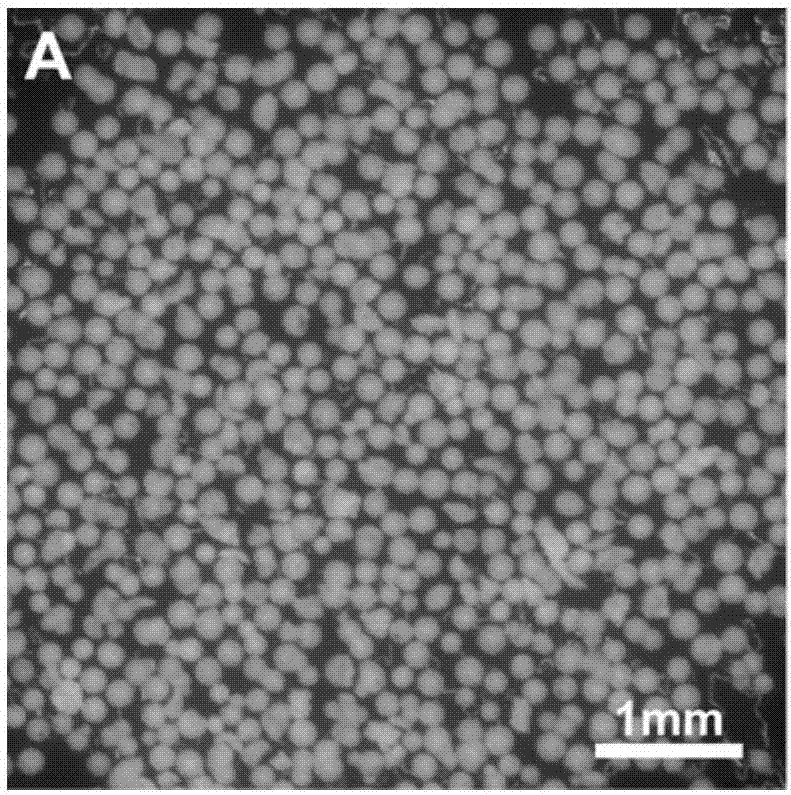

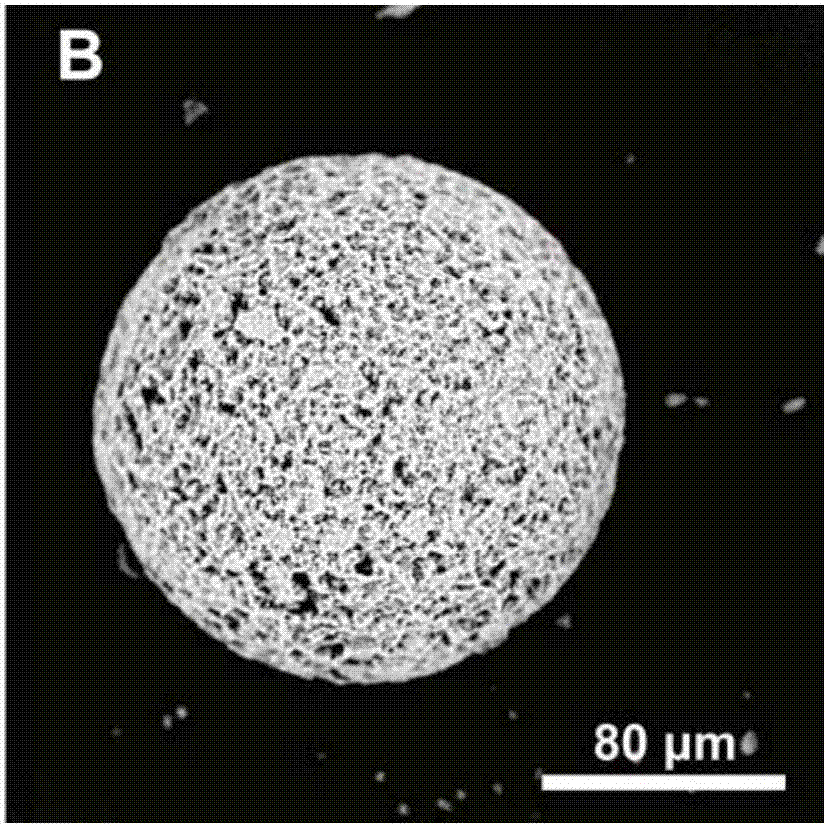

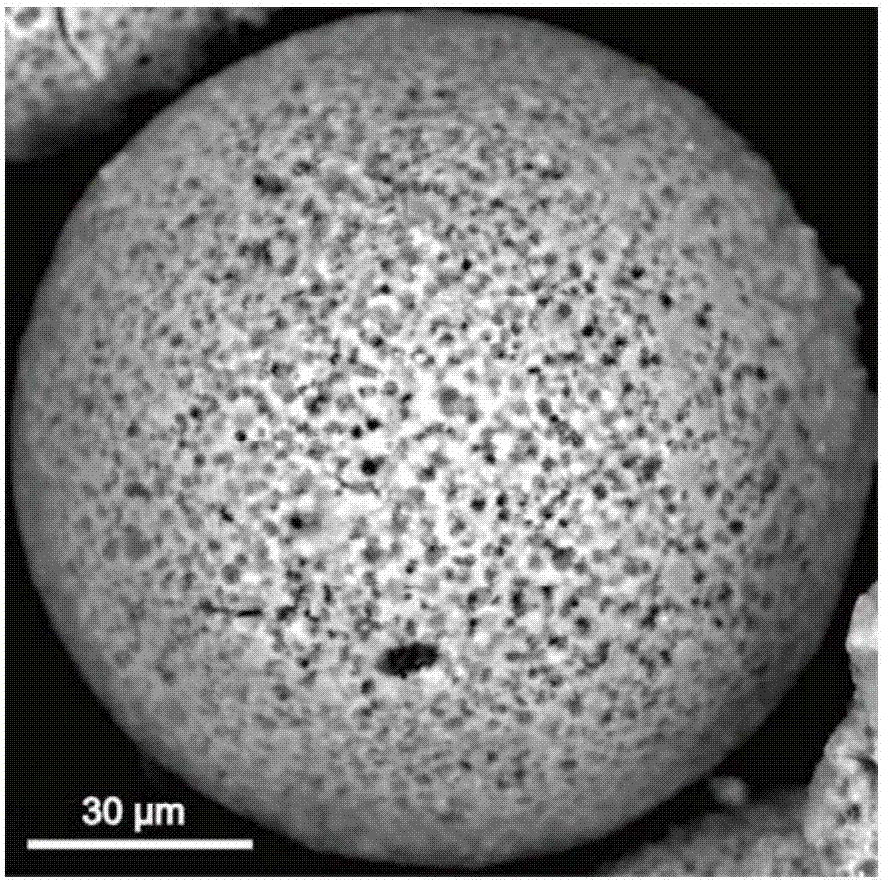

Preparation method and application of porous geological polymer microspheres

A technology of geopolymers and microspheres, applied in applications, alkali metal compounds, other household appliances, etc., can solve the problems of cumbersome preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Slurry preparation: Mix and stir 30g slag and 12g liquid sodium silicate (modulus 2.5) to form a mixed slurry, and then slowly add the uniformly dispersed pore-forming agent aqueous solution (3g calcium carbonate + 5g water) to the mixed slurry Continue to stir in the material, mix evenly, stir at a speed of 500 rpm, and stir for 2 minutes to make the system a uniform slurry;

[0029] (2) Ball forming: drop the homogeneous slurry in step (1) into the hot dimethyl silicone oil dispersed at a high speed, the temperature is 50 degrees Celsius, and the stirring speed is 200 rpm;

[0030] (3) Curing: put the simethicone oil of step (2) and the obtained product together into an oven for curing and curing, the temperature is 60 degrees Celsius, and the curing and curing time is 1 hour;

[0031] (4) Filtration: the simethicone oil of step (3) and the resulting product thereof are subjected to vacuum filtration to obtain geopolymer microspheres;

[0032] (5) Calcination: ca...

Embodiment 2

[0036] (1) Slurry preparation: Mix and stir 20g slag and 8.57g liquid sodium silicate (modulus 1.5) to form a mixed slurry, and then slowly add the uniformly dispersed pore-forming agent aqueous solution (10g calcium carbonate + 10g water) to mix Continue to stir in the slurry, mix evenly, the stirring speed is 1000 rpm, and stir for 1 minute, so that the system becomes a uniform slurry;

[0037] (2) Ball forming: drop the homogeneous slurry in step (1) into the hot dimethyl silicone oil dispersed at a high speed, the temperature is 100 degrees Celsius, and the stirring speed is 500 rpm;

[0038] (3) Curing: Put the simethicone oil of step (2) and the obtained product together into an oven for curing and curing, the temperature is 70 degrees Celsius, and the curing and curing time is 12 hours;

[0039] (4) Filtration: carry out vacuum filtration to the simethicone oil of step (3) and the product thereof, to obtain geopolymer microspheres;

[0040] (5) Calcination: calcining t...

Embodiment 3

[0044] (1) Slurry preparation: 20g metakaolin, 10g slag and 12g sodium hydroxide solution (concentration 10 moles) were mixed and stirred evenly to form a mixed slurry, and then the uniformly dispersed pore-forming agent aqueous solution (2g polymethyl methacrylate +25g water) slowly added to the mixed slurry and continued to stir, mixed evenly, the stirring speed was 300 rpm, and stirred for 5 minutes to make the system a uniform slurry;

[0045] (2) Ball forming: drop the homogeneous slurry in step (1) into the hot simethicone oil dispersed at a high speed, the temperature is 90 degrees Celsius, and the stirring speed is 700 rpm;

[0046] (3) Curing: put the simethicone oil of step (2) and the obtained product together into an oven for curing and curing, the temperature is 90 degrees Celsius, and the curing and curing time is 1 hour;

[0047] (4) Filtration: the simethicone oil of step (3) and the resulting product thereof are subjected to vacuum filtration to obtain geopolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com