Preparation method of ordered mesoporous silica microspheres with hollow structures

A technology of mesoporous silica and hollow structure, applied in the direction of silica, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of time-consuming preparation process, high cost, unsuitable for expanding production, etc. Achieve the effects of uniform spherical shape and size, low equipment requirements, and good polar solvent dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

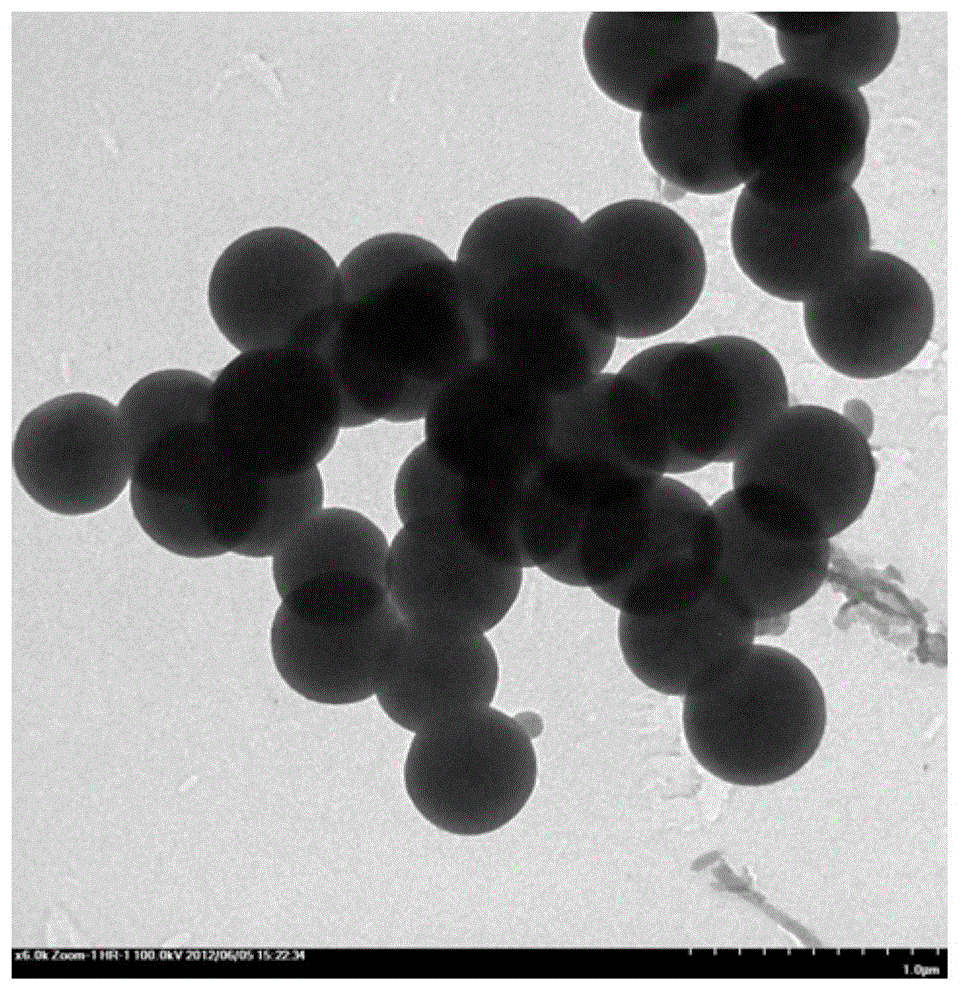

[0033] (1) Dissolve 0.08 g of cetyltrimethylammonium bromide in a mixed solution of 30 ml of ethanol and 50 ml of water, and mix 1 ml of concentrated ammonia water (the concentrated ammonia water contains Ammonia NH 3 The mass percentage concentration is 25~28%) and 1 ml tetraethyl orthosilicate were added to the mixed solution, and reacted for 12 h to obtain white solid silica microspheres ( figure 1 );

[0034] (2) The silica obtained in step (1) was centrifuged and washed with water, transferred to water to prepare a silica dispersion (2 mg / ml), and stirred at 50 °C for 20 h;

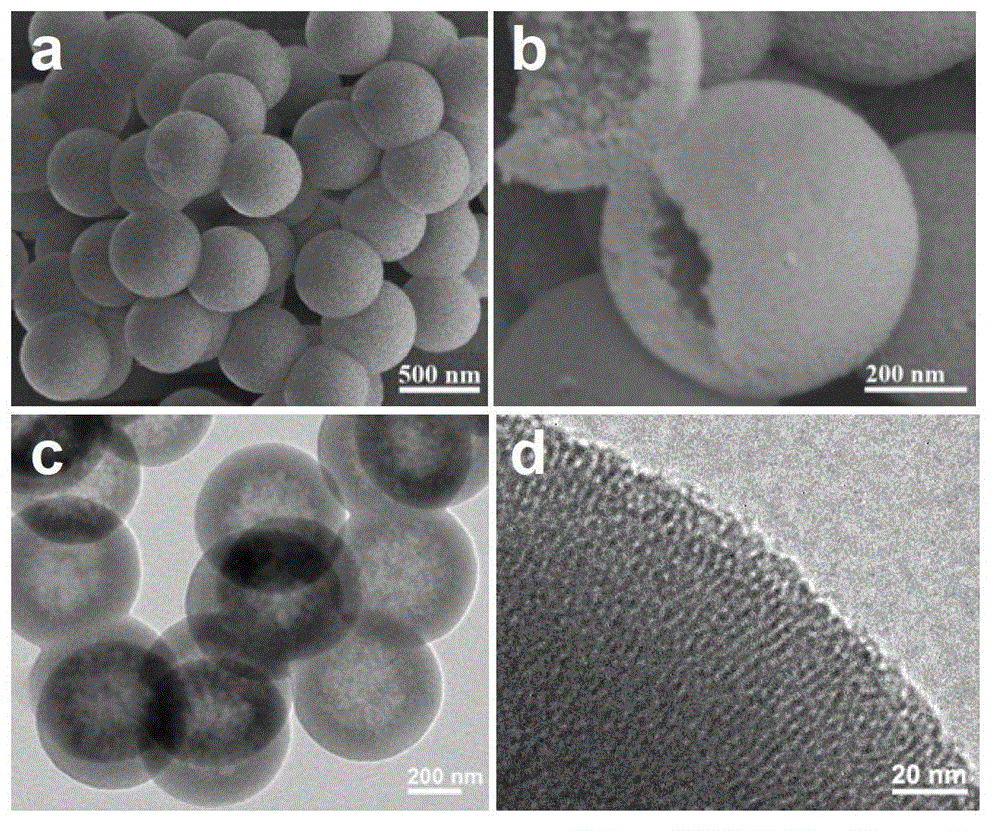

[0035] (3) The reaction product obtained in step (2) was centrifuged, washed with water, and dried; calcined at 550 °C for 6 h to obtain ordered mesoporous silica microspheres with a hollow structure (see figure 2 ).

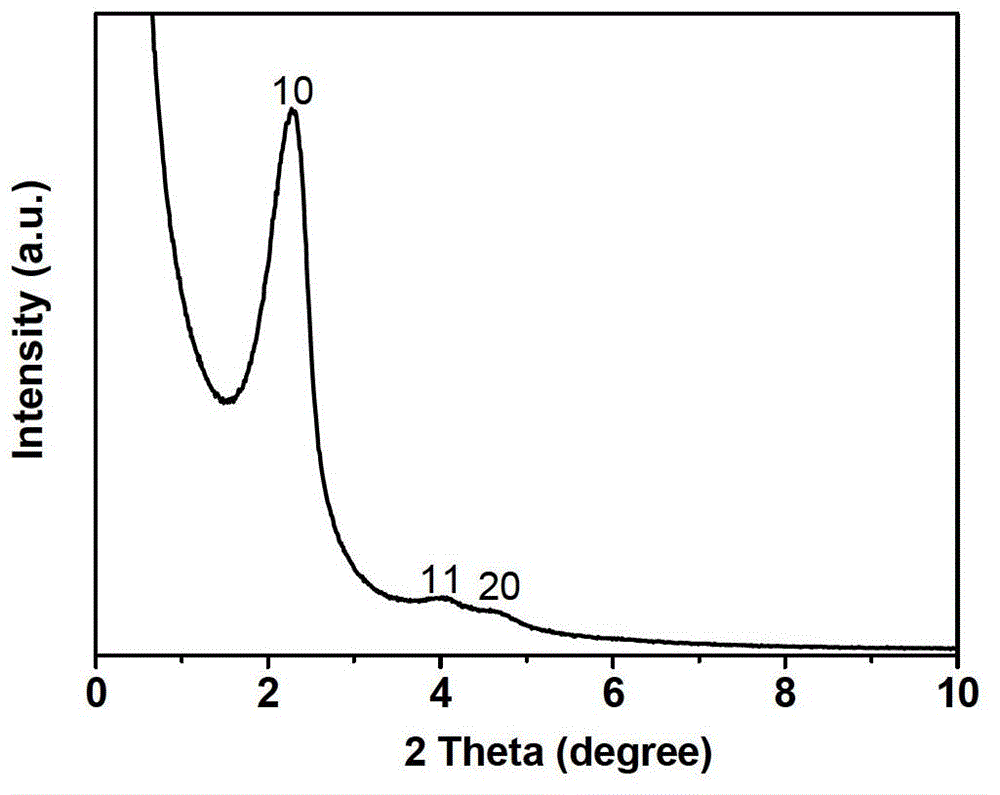

[0036]The silica obtained through step (1) is a solid sphere with spherical morphology. The obtained ordered mesoporous silica microspheres with a hollow structure have a particle...

Embodiment 2

[0038] (1) Dissolve 0.08 g of dodecyltrimethylammonium bromide in a mixed solution of 15 ml of ethanol and 100 ml of water, and mix 0.5 ml of concentrated ammonia water (the concentrated ammonia water contains Ammonia NH 3 The mass percentage concentration is 25~28%) and 0.5 ml tetraethyl orthosilicate were added to the mixed solution, and reacted for 24 h to obtain white solid silica microspheres;

[0039] (2) Centrifuge and wash the silica obtained in step (1), transfer it to water to prepare a silica dispersion (0.1 mg / ml), and stir at 20 °C for 1 h;

[0040] (3) The reaction product obtained in step (2) was centrifuged, washed with water, and dried; calcined at 500 °C for 6 h to obtain ordered mesoporous silica microspheres with a hollow structure.

[0041] The obtained ordered mesoporous silica microspheres with a hollow structure have a particle size of 210 nm, a hollow structure, and a shell thickness of about 40 nm; the mesoporous channels are radial and have a hexago...

Embodiment 3

[0043] (1) Dissolve 0.08 g of cetyltrimethylammonium bromide in a mixed solution of 60 ml of ethanol and 25 ml of water, and mix 1.9 ml of concentrated ammonia water (the concentrated ammonia water contains Ammonia NH 3 The mass percent concentration is 25~28%) and 1.9 ml tetraethyl orthosilicate were added to the mixed solution, reacted for 3 h, and white solid silica microspheres were obtained;

[0044] (2) The silica obtained in step (1) was centrifuged and washed with water, transferred to water to prepare a silica dispersion (5 mg / ml), and stirred at 90 °C for 120 h;

[0045] (3) The reaction product obtained in step (2) was centrifuged, washed with water, and dried; calcined at 600 °C for 7 h to obtain ordered mesoporous silica microspheres with a hollow structure.

[0046] The obtained ordered mesoporous silica microspheres with a hollow structure have a particle size of 780 nm, a hollow structure, and a shell thickness of about 60 nm; the mesoporous channels are radia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com