Method for producing hydrogenation catalyst with fluidized bed

A technology for hydrotreating and catalyst, which is used in the treatment of hydrocarbon oil, the treatment of moving solid particles, and the petroleum industry. Effects of mechanical strength and wear resistance, reduced olefin and aromatic content, reduced losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of modified alumina G-1

[0042] Take the filter cake after washing the alumina precursor prepared by the carbonization method, measure its dry basis as 30wt%, take 1500 grams of the filter cake, add 2.5 liters of deionized water, make a slurry, heat up to 65 ° C, stir for 1 hour, add 90 gram of 85m% phosphoric acid solution, filtered to obtain a filter cake, added 2.0 liters of deionized water, beating, heated to 70 ° C, and added 86 grams of boric acid, and with a concentration of 10gNH 3 / 100ml of ammonia solution to adjust the pH value of the solution to 6, stir for 1 hour, filter and dry at 110°C for 4 hours, the sample is G-1, and its physical and chemical properties are shown in Table 1.

Embodiment 2

[0044] Preparation of modified alumina G-2.

[0045] Take 800 grams of filter cake after washing the aluminum oxide precursor prepared by the aluminum sulfate method, the dry basis is 30wt%, add 3 liters of deionized water, stir evenly, heat up to 85 ° C, and add 53 grams of 85m% phosphoric acid solution, filter to obtain Cake, add 2.5 liters of deionized water, make a slurry, heat up to 70 ° C, and add 120 grams of boric acid, and use a concentration of 10 g NH 3 Adjust the pH of the solution to 6.5 per 100ml of ammonia solution, stir for 1 hour, continue stirring for 30 minutes, and dry at 110°C for 4 hours. The physical and chemical properties of sample G-2 are shown in Table 1.

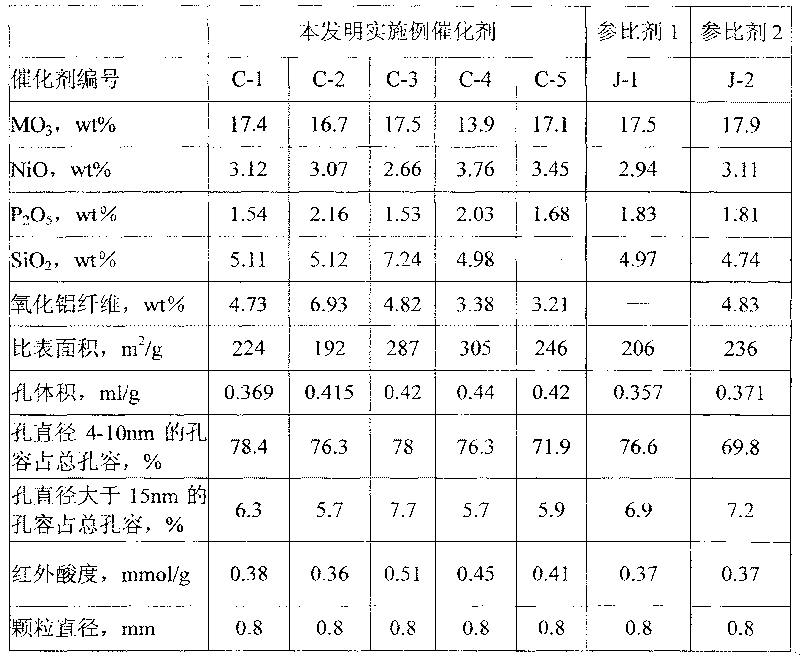

[0046] Table 1 Physicochemical properties of samples

[0047] Example number

Embodiment 3

[0049] Preparation of ebullating bed hydrogenation catalyst C-1 for stable hydrogenation of heavy oil products of the present invention.

[0050] With 168 grams of G-1 and 18 grams of alumina fiber powder (length 30 microns, diameter 6 microns, specific surface 183m 2 / g, pore volume 0.08ml / g) is uniformly wetted with 238ml S-1 solution; 19 grams of nano-silica (the pure nano-silica produced by Tianjin Chemical Co., Ltd.) and 193.5 grams of SB powder (pore volume 0.46 ml / g, specific surface area 260m 2 / g) add the adhesive (30wt% on a dry basis, the acid-aluminum mol ratio is 0.3) of peptizing acid preparation, put into the roller compactor, grind to extrudable paste, extrusion, 110 ℃ of drying 4 hours, 550 ℃ for 3 hours to prepare catalyst C-1. The physical and chemical properties of the catalyst are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com