Method for recycling hydrogenation catalyst waste

A technology for hydrogenation catalyst and waste material, which is applied in the field of recycling and reuse of hydrogenation catalyst waste material, can solve problems such as affecting the physicochemical properties of the catalyst, and achieve the effects of efficient recovery, high activity and reduced content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

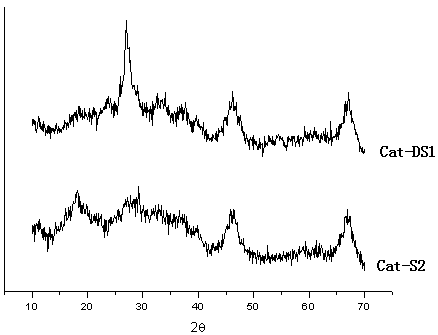

Image

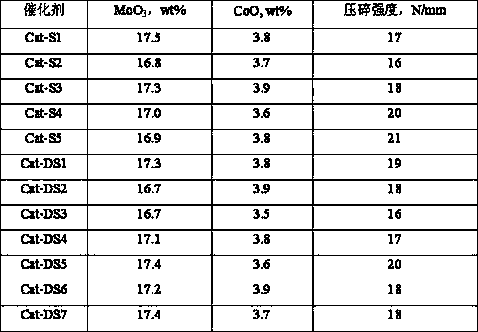

Examples

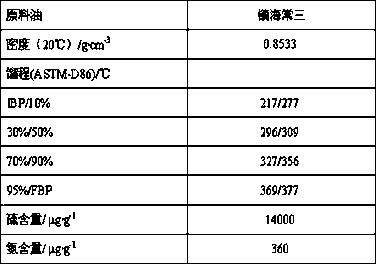

Embodiment 1

[0038] Hydrogenation catalyst waste (containing 18.7 wt%MoO 3 and 2.8 wt% CoO, the balance being alumina) and weighed 18g after passing through a 200-mesh sieve. Add it to 18g of water for dispersion, then add 15g of 30% nitric acid, 10.6g of 85% phosphoric acid, 5.4g of malic acid and 50g of mixed acid solution of water. At this time, the mass ratio of nitric acid-phosphoric acid-organic acid-waste material-water is 0.25:0.5:0.3:1:4.45. Then the temperature was raised to 85° C., and then kept at the temperature for 60 minutes. After cooling to room temperature, 2 g of isopropylamine was added to obtain the final waste material sol slurry.

[0039] After mixing 185g of alumina powder (dry basis 75%) and 3.75g of turnip powder evenly, add the above-mentioned waste material sol slurry, add 105g of water, roll and knead to obtain a plastic body and extrude. Then, it was dried at 110°C for 4 hours, and calcined at 700°C for 3 hours to obtain carrier S1.

[0040] According to th...

Embodiment 2

[0042] Hydrogenation catalyst waste (containing 12 wt% MoO 3 and 2.1 wt% NiO, the balance being alumina) and weighed 15g after passing through a 200-mesh sieve. Add it to 20g of water for dispersion, then add 15g of 30% nitric acid, 10.5g of 85% phosphoric acid, 7.5g of tartaric acid and 65g of mixed acid solution of water. At this time, the mass ratio of nitric acid-phosphoric acid-organic acid-waste material-water is 0.3:0.6:0.5:1:6.8. Then the temperature was raised to 90° C., and then kept at the temperature for 60 minutes. After cooling to room temperature, 3 g of monoethanolamine was added to obtain the final waste material sol slurry.

[0043] After mixing 140g of alumina powder (dry basis 75%) and 4g of scallop powder evenly, add the above-mentioned waste material sol slurry, add 108g of water, roll and knead to obtain a plastic body and extrude. Then, it was dried at 110° C. for 4 hours and calcined at 750° C. for 3 hours to obtain carrier S2.

[0044] According to...

Embodiment 3

[0046] Hydrogenation catalyst waste (containing 22.5 wt%MoO 3 and 3.1 wt% NiO, the balance being alumina) and weighed 20g after passing through a 180-mesh sieve. Add to 25g water for dispersion, then add 40g of 30% nitric acid, 14.1g of 85% phosphoric acid, 4g of citric acid and 35g of mixed acid solution of water. At this time, the mass ratio of nitric acid-phosphoric acid-organic acid-waste material-water is 0.6:0.6:0.2:1:4.5. Then heat up to 90°C and keep the temperature for 60 minutes, then add 4g of ethylenediamine after cooling to room temperature to obtain the final waste material sol slurry.

[0047] After mixing 230g of alumina powder (dry basis 75%) and 4g of scallop powder evenly, add the above-mentioned waste material sol slurry, add 138g of water, roll and knead to obtain a plastic body and extrude. Then, it was dried at 110° C. for 4 hours and calcined at 800° C. for 3 hours to obtain carrier S3.

[0048] According to the conventional preparation method of imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com