Heavy oil hydrogenation catalyst with high desulfurization activity and preparation method thereof

A heavy oil hydrogenation and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, hydrocarbon oil treatment, etc. Advanced problems, to achieve the effect of improving dispersion, avoiding strong interactions, and being easy to vulcanize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

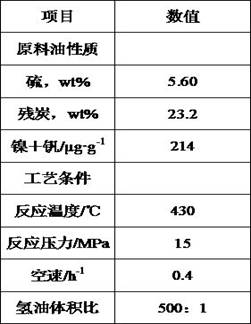

Method used

Image

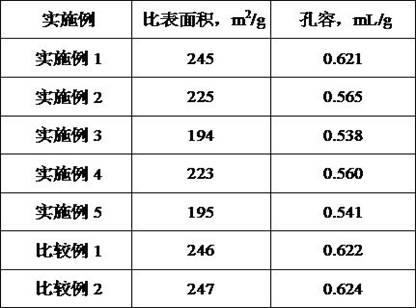

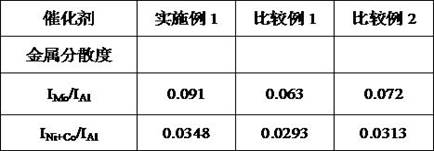

Examples

Embodiment 1

[0041] (1) Carrier preparation

[0042] First, n-valeric acid was added to deionized water, and it was completely dissolved by stirring at 50 °C to prepare an aqueous solution of n-valeric acid with a concentration of 0.05 g / mL. Then 100g alumina carrier (made from commercially available pseudo-boehmite powder, obtained by kneading, molding and roasting, spherical carrier, particle size 0.3~0.8mm, specific surface area is 285m 2 / g, the pore volume is 0.772 mL / g) into the prepared 800mL n-valeric acid aqueous solution, soak for 15min, then take out the alumina carrier and put it in a fat extractor for extraction. The aqueous solution of valeric acid, the temperature is 90 ℃, and the extraction time is 8h. The carrier after extraction was subjected to low temperature heat treatment at 110 °C for 8 h to obtain the treated alumina carrier.

[0043] (2) Catalyst preparation

[0044] 14.36g of molybdenum oxide, 4.73g of basic nickel carbonate, 0.52g of basic cobalt carbonate and...

Embodiment 2

[0049] (1) Carrier preparation

[0050] First, n-decanoic acid was dissolved in petroleum ether, and it was completely dissolved by stirring at 40 °C to prepare a n-valeric acid solution with a concentration of 0.06 g / mL. Then 100g alumina carrier (made from commercially available pseudo-boehmite powder, obtained by kneading, molding and roasting, spherical carrier, particle size 0.3~0.8mm, specific surface area is 285 m 2 / g, the pore volume is 0.772 mL / g) into the prepared 700mL n-decanoic acid solution, soak for 15min, then take out the alumina carrier and put it into a fat extractor for extraction treatment. Decanoic acid petroleum ether solution, the temperature is 90 ℃, the extraction time is 8h. The carrier after extraction was subjected to low temperature heat treatment at 110 °C for 8 h to obtain the treated alumina carrier.

[0051] (2) Catalyst preparation

[0052] 18.82g of molybdenum oxide, 4.83g of basic nickel carbonate, 2.04g of basic cobalt carbonate and 6....

Embodiment 3

[0057] (1) Carrier preparation

[0058] First, citric acid was dissolved in deionized water, and it was completely dissolved by stirring at 50 °C to prepare an aqueous citric acid solution with a concentration of 0.07 g / mL. Then 100g alumina carrier (made from commercially available pseudo-boehmite powder, obtained by kneading, molding and roasting, spherical carrier, particle size 0.3~0.8mm, specific surface area is 285 m 2 / g, the pore volume is 0.772 mL / g) into the prepared 600mL citric acid aqueous solution, soak for 15min, then take out the alumina carrier and put it into a fat extractor for extraction, the solvent is citric acid soaked in the carrier Aqueous solution, the temperature is 90 ℃, the extraction time is 8h. The carrier after extraction was subjected to low temperature heat treatment at 110 °C for 8 h to obtain the treated alumina carrier.

[0059] (2) Catalyst preparation

[0060] 23.70g of molybdenum oxide, 4.35g of basic nickel carbonate, 4.27g of basic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com