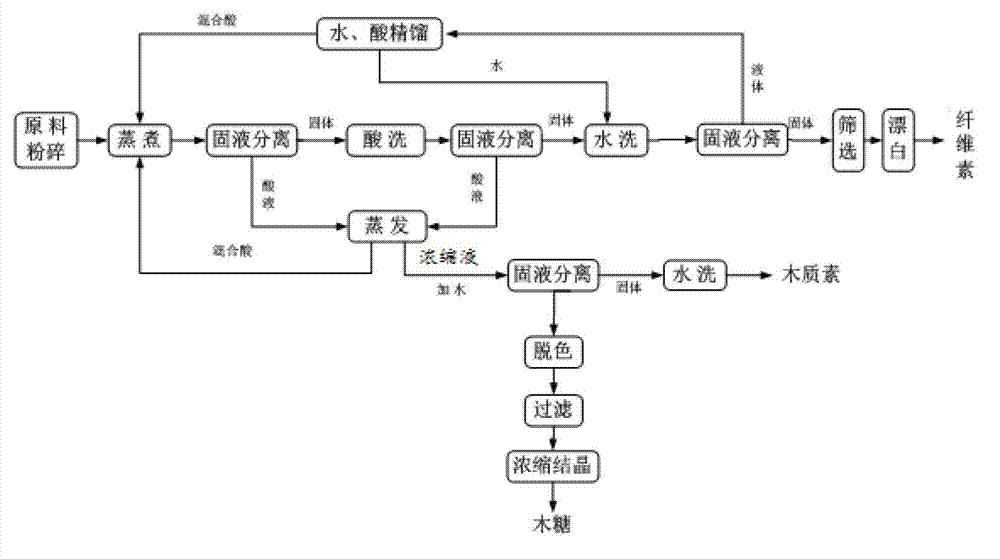

Comprehensive utilization process of biomass raw material

A biomass raw material and process technology, which is applied to pulping with organic solvents, non-woody plant/crop pulp, pulp bleaching, etc., can solve the problems of low component yield and low purity, and achieve high extraction efficiency and reduce The effect of destroying and shortening the cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this example, the biomass raw material is reed (ingredient composition: cellulose 49.5%, hemicellulose content 22.7%, lignin 18.9%), first crushed, washed with water to remove dust and crushed to a particle size of 0.5 -20cm.

[0053] The present embodiment comprises the following steps from the comprehensive utilization process of the biomass raw material:

[0054] (1) After the biomass raw material is pulverized and pretreated, the biomass raw material after treatment is cooked by using an organic acid solution with a total acid concentration of 70% formic acid and acetic acid. The mass of acetic acid and formic acid in the organic acid solution of this embodiment The ratio is 1:1, and 3% hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 125°C, react for 60min, and have a solid-liquid mass ratio of 1:5, and carry out the first solid-liquid separation of the obtained reaction solution;

[0055] (2) adding the solid obtained by the so...

Embodiment 2

[0068] In this embodiment, the rice straw (mass component composition: mass component composition: 35.8% cellulose, 28.6% hemicellulose, 14.3% lignin) was first crushed to a particle size of 0.5-20 cm.

[0069] The present embodiment comprises the following steps from the comprehensive utilization technique of described rice straw:

[0070] (1) After the rice straw is crushed and pretreated, use the organic acid solution of formic acid and acetic acid with a total acid concentration of 80% to cook the treated reeds. The mass ratio of acetic acid and formic acid in the organic acid solution of the present embodiment is 1: 3.5, and before adding the straw raw material, add hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 130°C, react for 40min, and have a solid-liquid mass ratio of 1:7.5, and carry out the first solid-liquid separation of the obtained reaction solution;

[0071] (2) adding the solid obtained by the solid-liquid separation for the f...

Embodiment 3

[0084] In this embodiment, the biomass raw material is bamboo chips (mass component composition: 47.3% cellulose, 24.6% hemicellulose, 25.8% lignin), first crushed, washed with water to remove dust and crushed to a particle size of 0.5-20cm.

[0085] The comprehensive utilization technology of bamboo chip described in the present embodiment, comprises the steps:

[0086] (1) After the bamboo chips are pulverized and pretreated, use the organic acid solution that the total acid concentration is 92% formic acid and acetic acid to cook the treated bamboo chips, and the mass ratio of acetic acid and formic acid in the organic acid solution of the present embodiment is 1:4, and add 6% hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 135°C, react for 45min, and have a solid-liquid mass ratio of 1:6.5, and carry out the first solid-liquid separation of the obtained reaction solution;

[0087] (2) the solid that solid-liquid separation obtains for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com