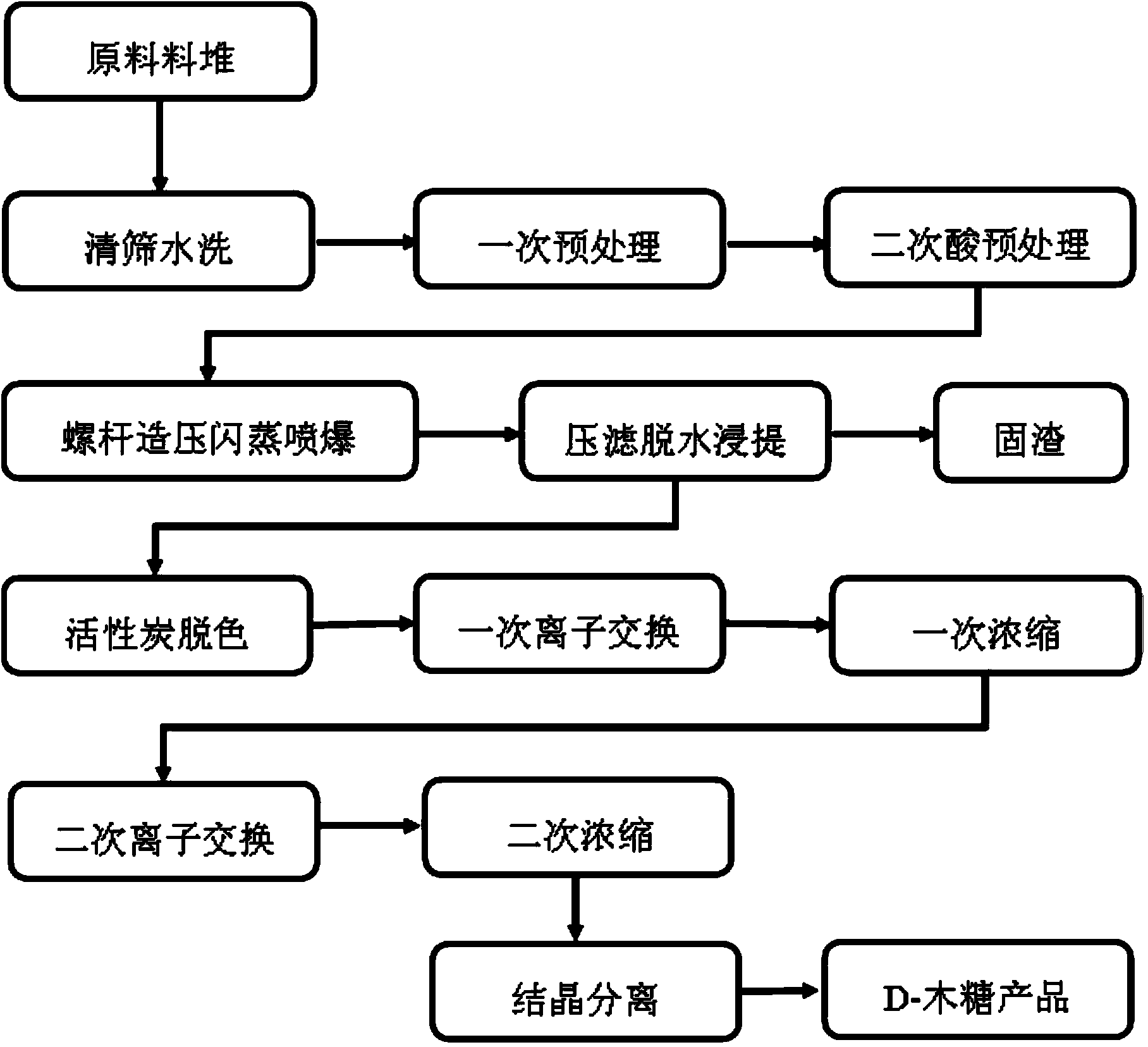

Clean technology for producing D-xylose with screw pressure producing flashing spray explosion method

A pressure-making and flashing technology, applied in chemical instruments and methods, monosaccharides, sugar derivatives, etc., can solve the problems of high water consumption, high resin consumption, low hydrolysis efficiency, and high cost, so as to improve quality and yield, reduce Effect of steam consumption and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concrete steps and process parameters of the present embodiment are as follows:

[0023] (1) Take 300Kg of corncob raw material, wash the raw material to remove dust, sundries and pigments until there are no sundries, add 1.2m 3 The mass fraction of 0.1% dilute sulfuric acid was treated at 120 ° C for 1 hour, the treatment liquid was discharged, and then 1.2 m 3 Deionized water, treated at 120 °C for 1 hour, and then discharged, and soaked the purified raw materials in 1.2m 3 In a sulfuric acid solution with a mass fraction of 0.35%, the soaking temperature is 65°C, and the soaking time is 6h; after the set soaking time is reached, the unabsorbed acid solution is pressed out and continues to be reused to obtain a water content of 43% of the dry weight. pretreated corncob;

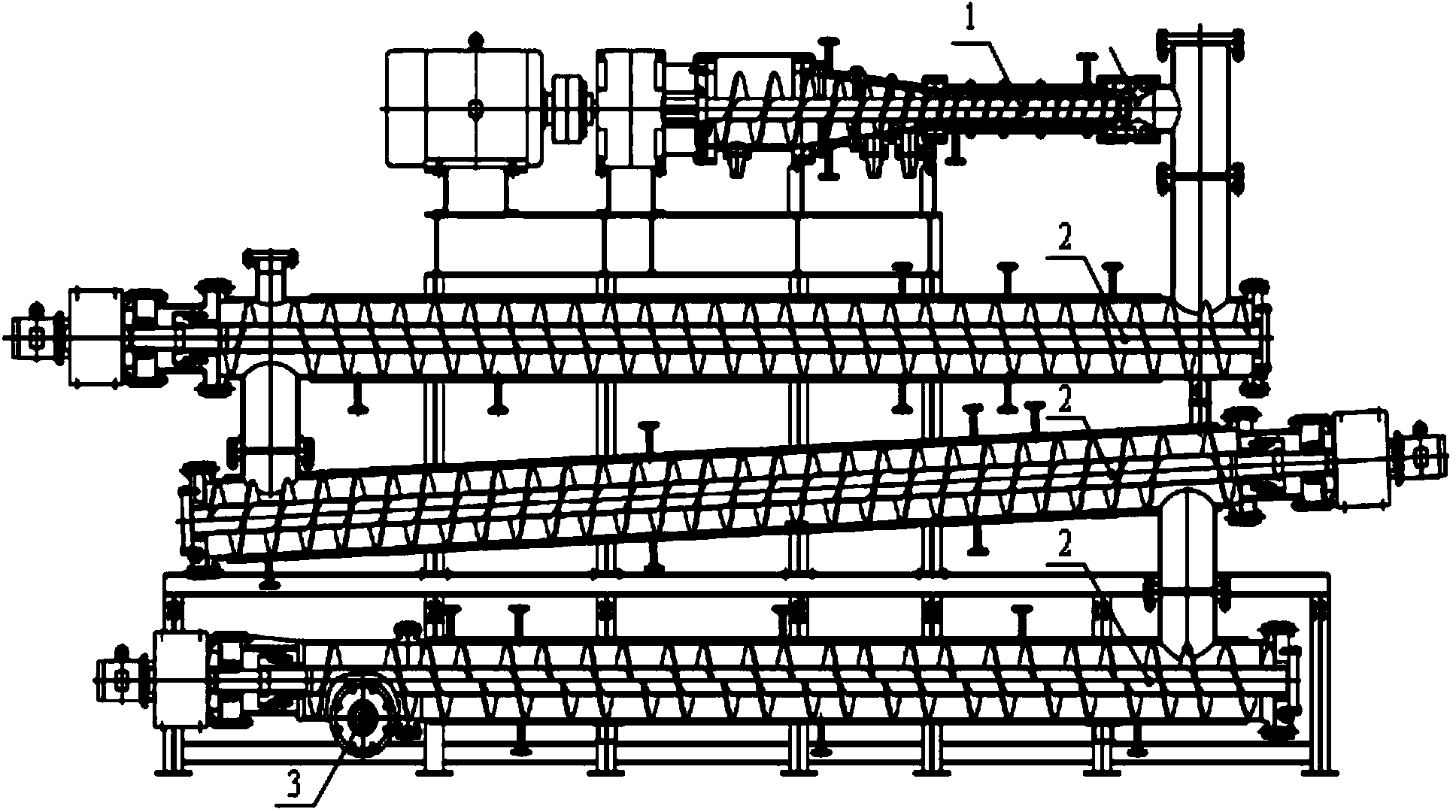

[0024] (2) The obtained pretreated corncob is transported to the screw pressure flashing and blasting device, and enters the screw extruder at the feeding port, and forms a solid under the acti...

Embodiment 2

[0028] The concrete steps and process parameters of the present embodiment are as follows:

[0029] (1) Take 200Kg of bagasse raw material, wash the raw material with water to remove dust, sundries and pigments until there are no sundries, add 1.0 m 3 The mass fraction of 0.15% dilute oxalic acid was treated at 90 °C for 1.5 hours, the treatment liquid was discharged, and then 1.0 m 3 Deionized water, treated at 90°C for 1.5 hours, then discharged, and soaked the purified raw materials in 1.0m 3In the oxalic acid solution with a mass fraction of 0.6%, the soaking temperature is 80 °C, and the soaking time is 12h; after the set soaking time is reached, the unabsorbed acid solution is pressed out and continues to be reused to obtain a water content of 38% of the dry weight. Pretreatment of bagasse;

[0030] (2) The obtained pretreated bagasse is transported to the screw pressure-making flash steaming and blasting device, and then enters the screw extruder at the feeding port, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com