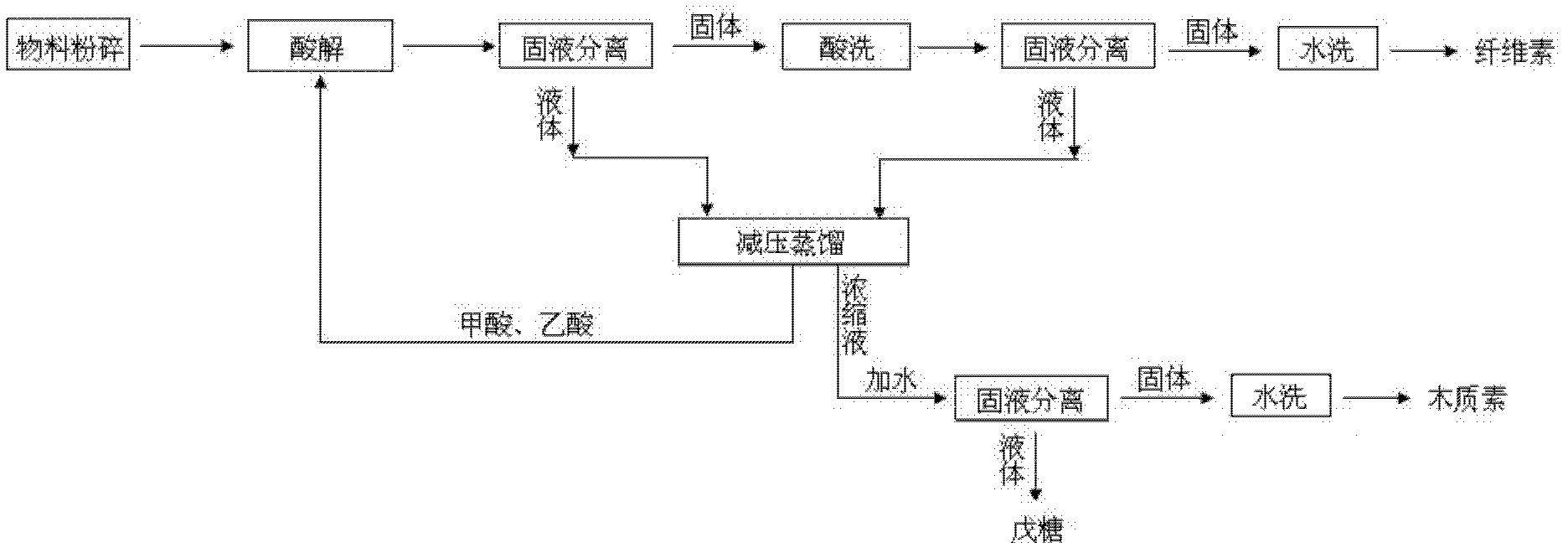

Comprehensive utilization process of lignocellulose biomass

A technology for lignocellulose and biomass, which is applied in the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of complex extraction process routes and affect the extraction efficiency of components, and achieves simple and guaranteed process routes. Activity and yield, the effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, first corncobs (mass component composition: moisture 18.73%, cellulose 39.33%, hemicellulose 30.73%, lignin 29.94%) are crushed, washed with water to remove dust and crushed to a particle size of 0.5-20cm , preferably 0.5-5cm.

[0048] The comprehensive utilization technique of lignocellulosic biomass described in this embodiment comprises the steps:

[0049] (1) After the biomass raw material is pulverized and pretreated, use an organic acid solution with a concentration of 90% formic acid and 5% acetic acid and 5% water to carry out acid hydrolysis of the treated lignocellulosic biomass to control the reaction The temperature was 165°C, and the reaction was carried out for 10 minutes. The liquid-solid mass ratio of the mixed acid solution of formic acid and acetic acid to the biomass raw material was 1:20, and the obtained reaction solution was subjected to solid-liquid separation for the first time;

[0050] (2) the organic acid solution that is ...

Embodiment 2

[0064] In this embodiment, first corncobs (mass component composition: moisture 18.73%, cellulose 39.33%, hemicellulose 30.73%, lignin 29.94%) are crushed, washed with water to remove dust and crushed to a particle size of 0.5-20cm , preferably 0.5-5cm.

[0065] The comprehensive utilization technique of lignocellulosic biomass described in this embodiment comprises the steps:

[0066] (1) After the biomass raw material is pulverized and pretreated, the lignocellulosic biomass after treatment is acid-hydrolyzed by using an organic acid solution containing 40% formic acid and 50% acetic acid and 10% water to control The reaction temperature is 110°C, the reaction is 180min, the liquid-solid mass ratio of the mixed acid solution of formic acid and acetic acid to the biomass raw material is 1:15, and the obtained reaction solution is subjected to solid-liquid separation for the first time;

[0067] (2) The solid that is separated in step (1) is added into the organic acid soluti...

Embodiment 3

[0081] In this embodiment, first corncobs (mass component composition: moisture 16.25%, cellulose 31.45%, hemicellulose 34.77%, lignin 33.78%) are crushed, washed with water to remove dust and crushed to a particle size of 0.5-20cm , preferably 0.5-5cm.

[0082] The comprehensive utilization technique of lignocellulosic biomass described in this embodiment comprises the steps:

[0083] (1) After the biomass raw material is crushed and pretreated, use an organic acid solution containing 50% formic acid and 40% acetic acid and 10% water to carry out acid hydrolysis on the treated lignocellulosic biomass, and control The reaction temperature is 135° C., the reaction is 30 minutes, the liquid-solid mass ratio of the mixed acid solution of formic acid and acetic acid to the biomass raw material is 1:5, and the obtained reaction solution is subjected to solid-liquid separation for the first time;

[0084] (2) the solid that is separated in the step (1) is added the formic acid that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com