Premixing device used for continuous acidolysis to produce titanium dioxide

A titanium dioxide, pre-mixed technology, applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of uneconomical enterprises, slow acidolysis rate, complex structure, etc., to achieve increased contact area, full reaction, The effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to elaborate on the present invention.

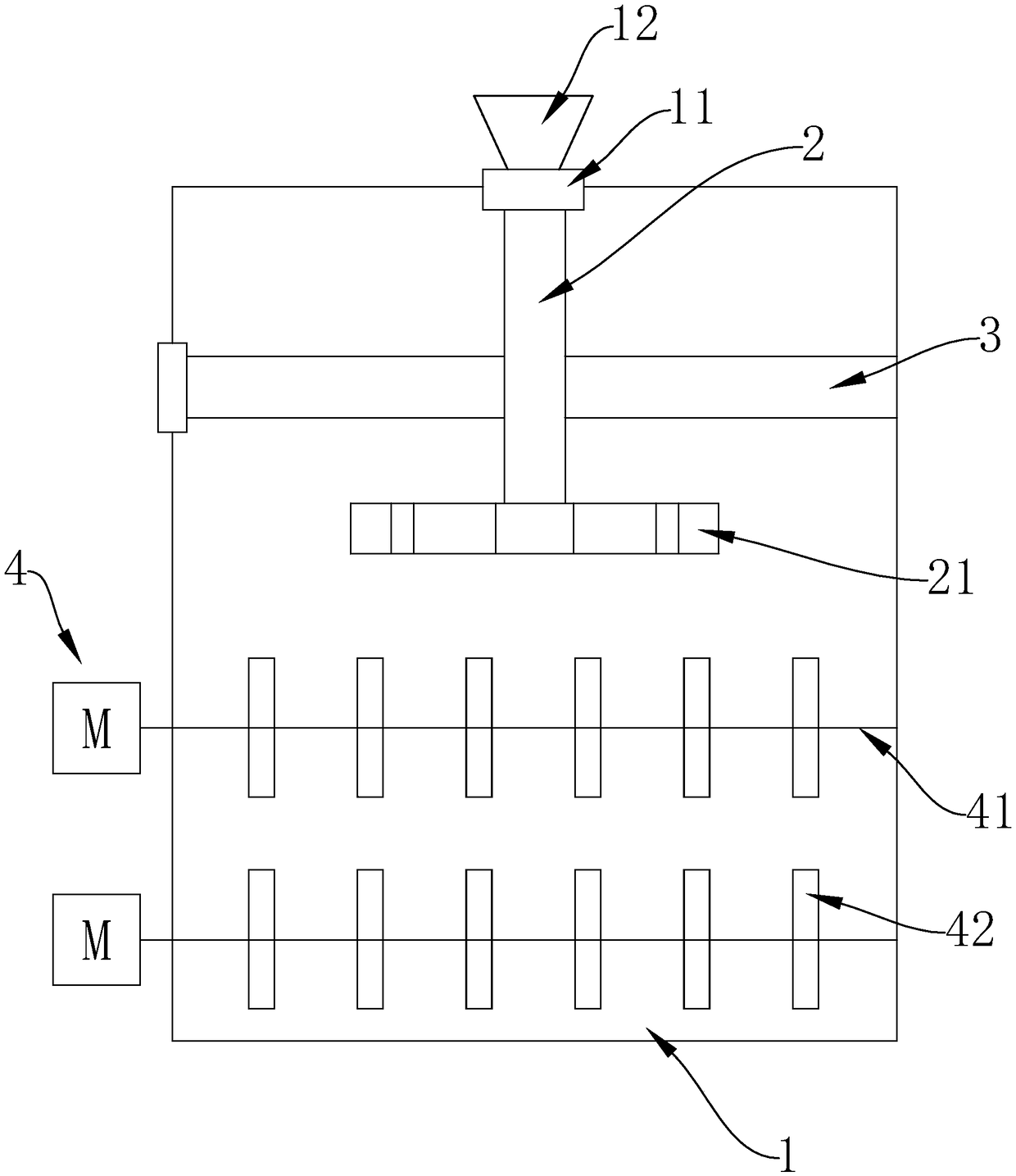

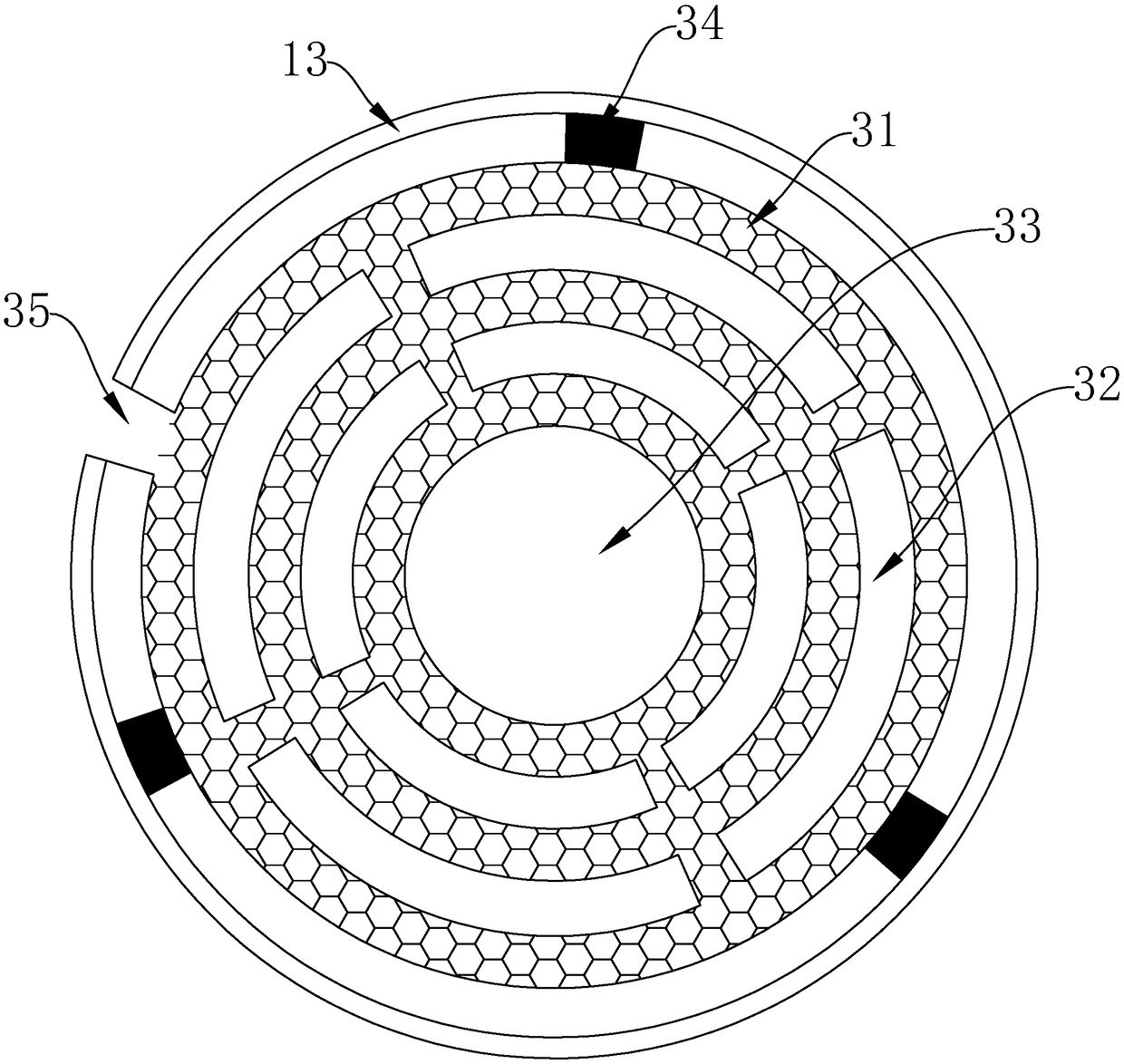

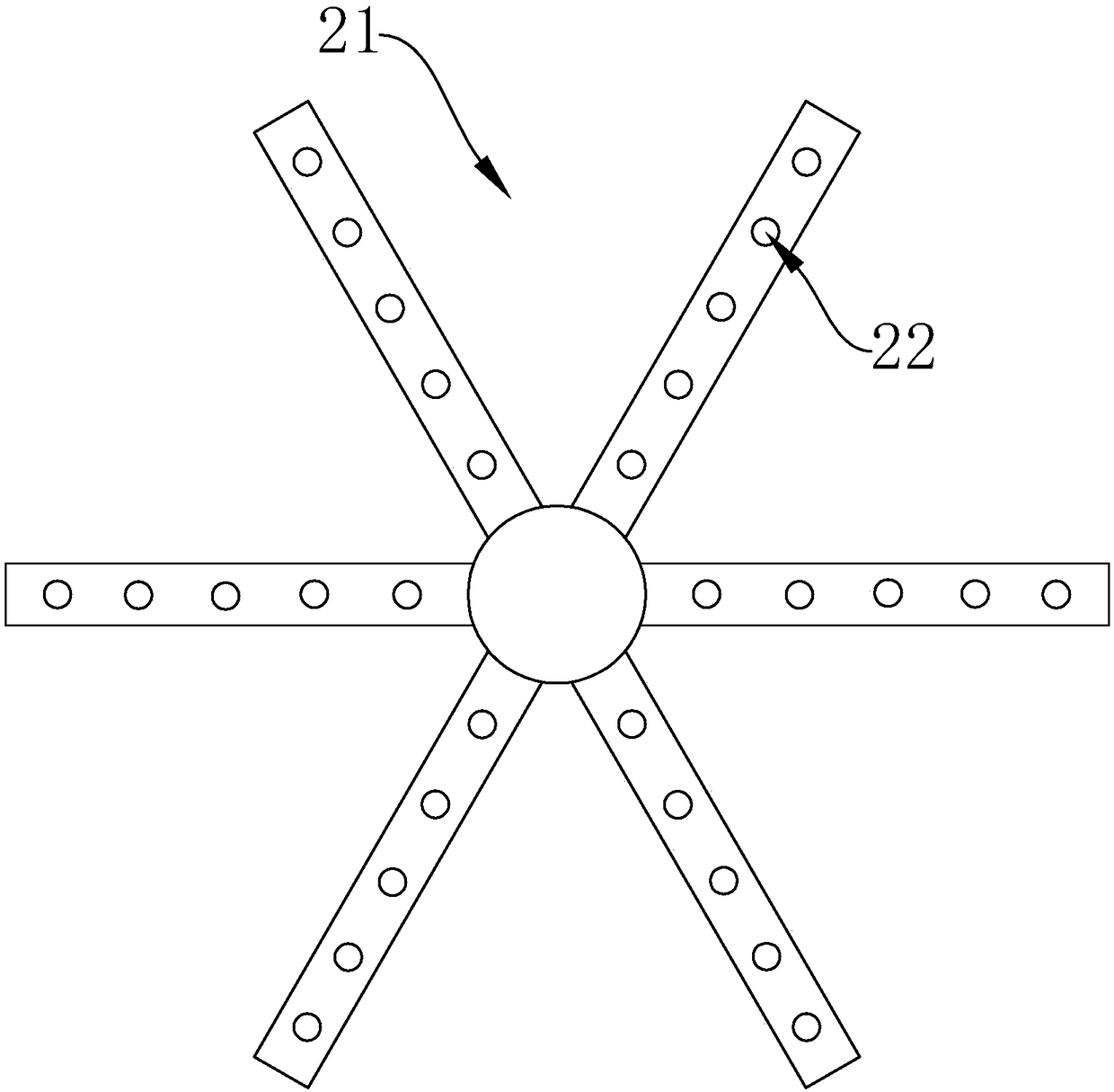

[0022] see figure 1 , figure 2 and image 3 As shown, a premixing device for continuous acidolysis production of titanium dioxide is shown, including a premixing tank 1 for reacting titanium ore powder and sulfuric acid, and the top of the premixing tank 1 is provided with an ore powder input port 11, and the ore powder The input port 11 is connected outwards (that is, toward the outside of the premixing tank 1) with a mineral powder silo 12, and the mineral powder input port 11 is connected with a mineral powder pipe 2 inward (that is, toward the inside of the premixing tank 1), and the titanium ore powder is transported to the Premix tank 1. The upper part of the premix tank 1 is provided with a spray mechanism 3, which is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com