Washing machine, and dehydration barrel assembly and water spraying cover plate

A washing machine and dewatering bucket technology, applied in the field of washing machines, can solve the problems of high entanglement risk of clothes, dead corners of spraying, etc., and achieve the effects of reducing the probability of dead corners of spraying, facilitating processing and forming, and improving energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

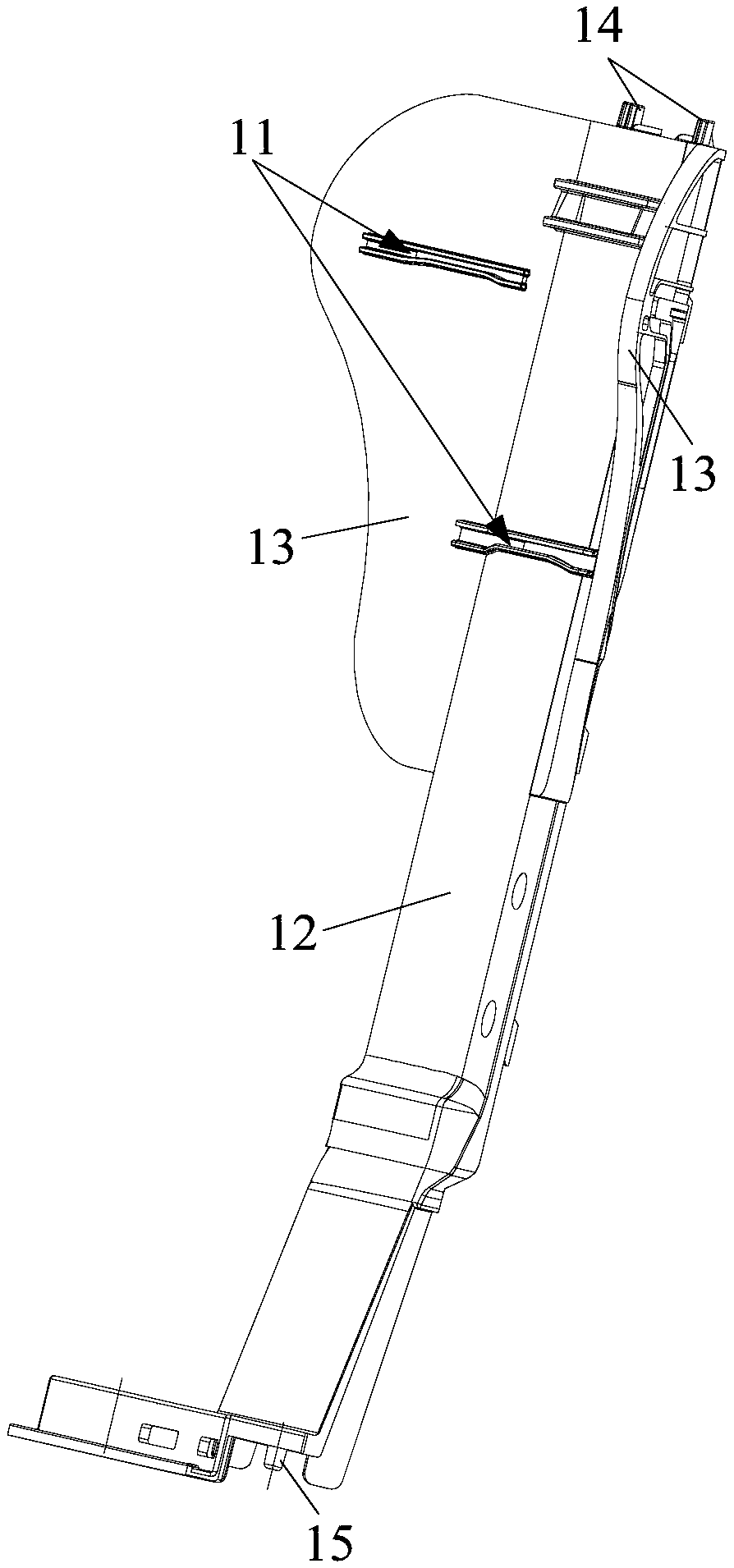

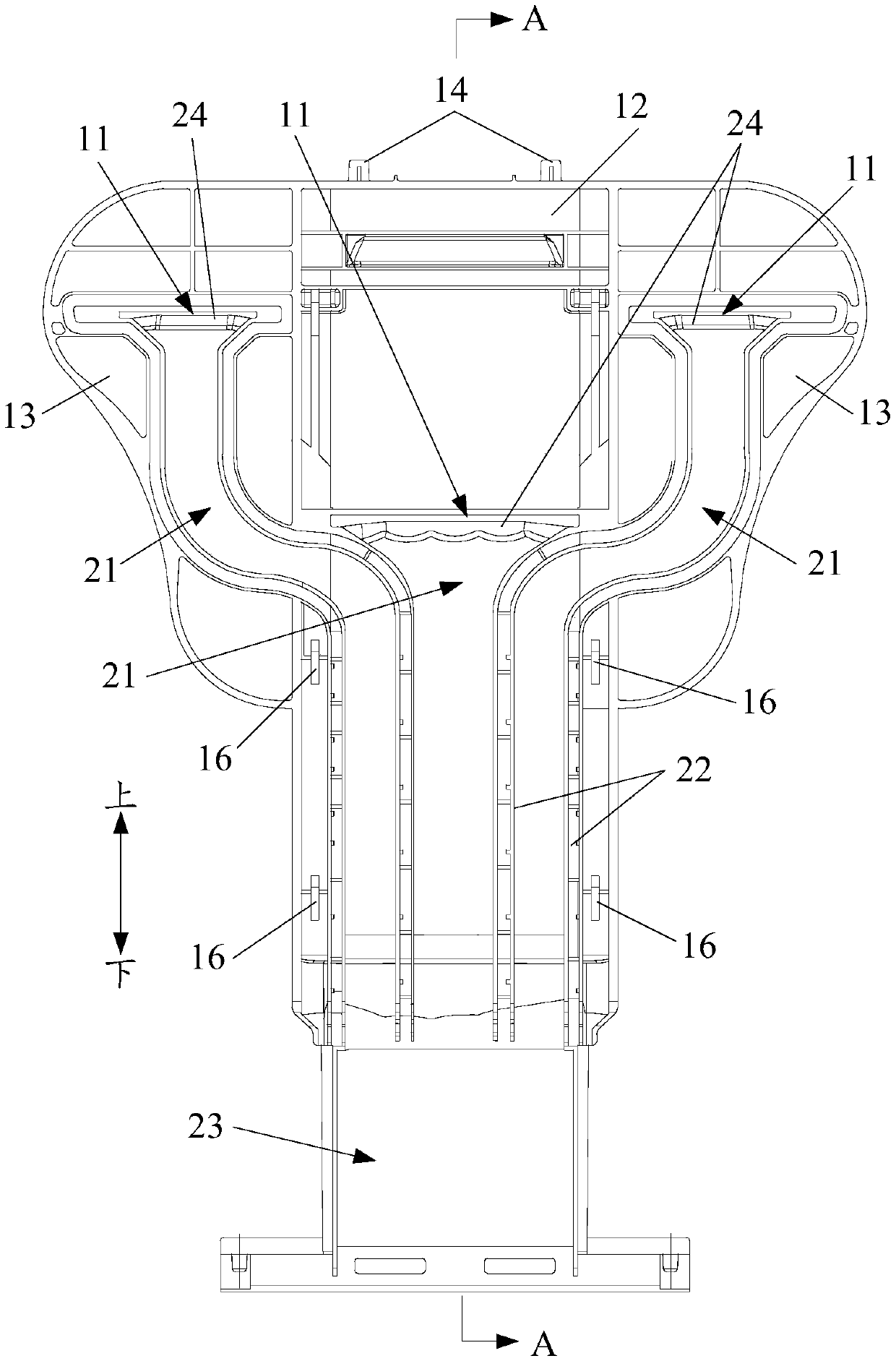

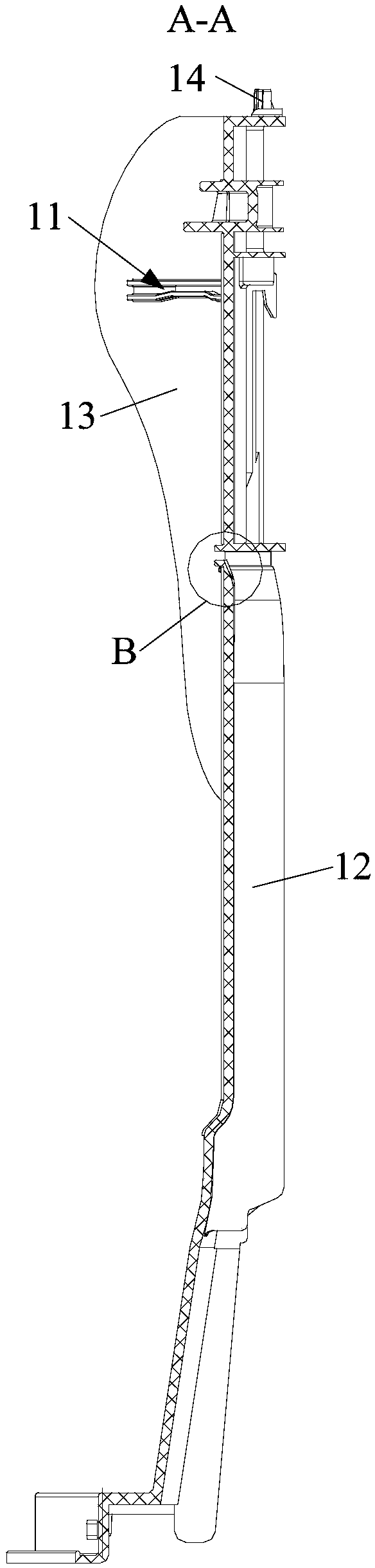

[0080] The positions of a plurality of waterfall holes 11 have different heights, such as figure 1 and figure 2 shown.

[0081] In the prior art, there is only one waterfall hole 11 and its position is fixed, so when the water level is low, the water pressure may not be enough to lift the water flow to the waterfall hole 11. Clothes are sprayed with water, causing the clothes to be easily entangled.

[0082] Based on this, the application makes the positions of multiple spray holes 11 have different heights by rationally arranging the positions of the multiple spray holes 11, so that the lower spray holes 11 can play an important role when the water level is low. Waterfall effect, while the waterfall hole 11 at a higher position can play a major role in the waterfall function when the water level is higher, thereby meeting the waterfall needs of different water levels, so that the washing machine has the function of adjusting the spray effect according to different water le...

Embodiment 2

[0087] Embodiment two (not shown in the figure)

[0088] The difference from Embodiment 1 is that: there are at least three waterfall holes 11, and the positions of the waterfall holes 11 gradually decrease from the middle to both sides.

[0089] The number of waterfall holes 11 is at least three, and the position of the waterfall holes 11 gradually decreases from the middle to the two sides, that is, a plurality of waterfall holes 11 are arranged in an inverted pyramid structure, which is beneficial to increase the horizontal spray coverage The area is also conducive to increasing the longitudinal spray coverage area, thereby significantly improving the spray coverage space and further improving the spray effect; and the structure is relatively regular, which is convenient for processing and forming; at the same time, it also avoids adjacent spray holes. 11 The jetted water flow overlaps and interferes to cause energy loss, thereby improving the energy utilization rate.

Embodiment 3

[0091] A plurality of waterfall holes 11 are distributed staggered up and down, such as figure 1 and figure 2 shown.

[0092] A plurality of waterfall holes 11 are distributed alternately up and down, that is, alternately distributed up and down, the structure is relatively regular, which is convenient for processing and forming, and avoids overlapping and interference of the water jets sprayed from adjacent waterfall holes 11, resulting in energy loss, thereby Improved energy utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com