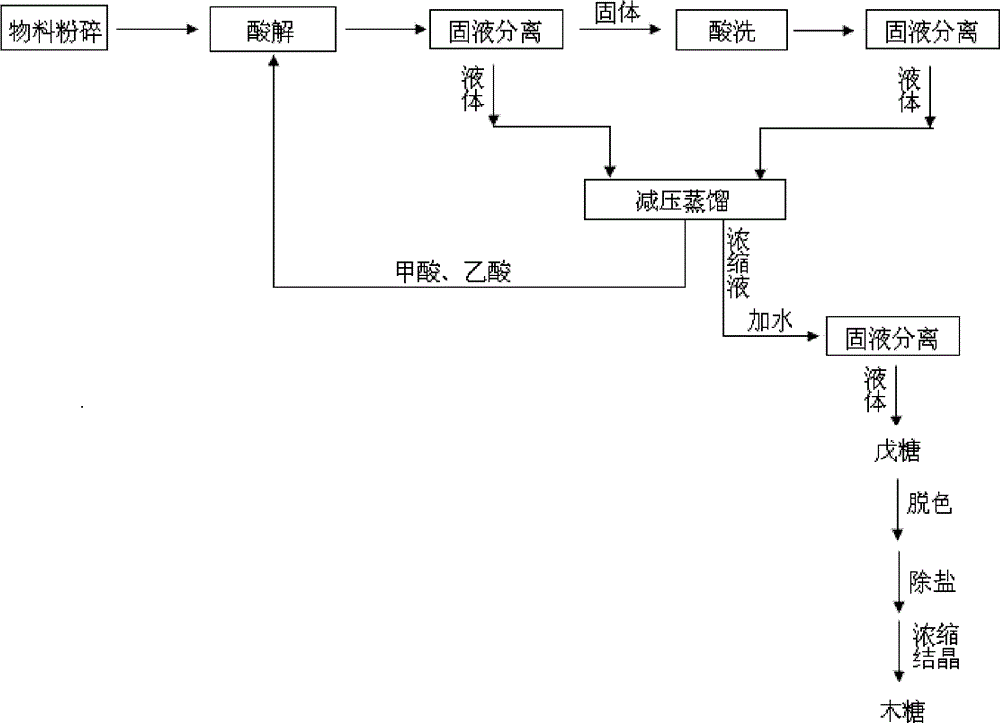

Process for producing xylose by lignocellulose biomass

A technology of lignocellulose and biomass, applied in sugar production, sugar production, food science, etc., can solve the problems of complex extraction process, high acid-base energy consumption, etc., achieve simple process route, high acidolysis efficiency, avoid Dealing with Difficult Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, first corn cobs (mass composition: moisture 6.12%, cellulose 35.19%, hemicellulose 32.1%, lignin 23.7%, other 2.95%) are broken, washed with water to remove dust and crushed to particle size 0.5-20cm, preferably 2-5cm.

[0048] The comprehensive utilization technique of lignocellulosic biomass described in this embodiment comprises the steps:

[0049] (1) After 106.52g of corncob raw material is pulverized and pretreated, use a concentration of 30% formic acid and a concentration of 50% acetic acid and 20% water to acid hydrolyze the treated lignocellulosic biomass, and control the reaction temperature at 120 ℃, reacted for 300min, the liquid-solid mass ratio of the mixed acid liquid of the formic acid and acetic acid to the biomass raw material was 1:6, and the obtained reaction liquid was subjected to solid-liquid separation for the first time;

[0050] (2) adding 30% formic acid and 50% acetic acid to the solid separated in step (1) for acid wash...

Embodiment 2

[0056] In this embodiment, first corn cobs (mass composition: moisture 6.12%, cellulose 35.19%, hemicellulose 32.1%, lignin 23.7%, other 2.95%) are broken, washed with water to remove dust and crushed to particle size It is 2-5cm.

[0057] The comprehensive utilization technique of lignocellulosic biomass described in this embodiment comprises the steps:

[0058] (1) After 532.6 kg of biomass raw material is pulverized and pretreated, the lignocellulosic biomass after treatment is acid-hydrolyzed with 80% formic acid and 10% acetic acid and 10% water, and the reaction temperature is controlled at 90 ℃, reacted for 600min, the liquid-solid mass ratio of the mixed acid solution of formic acid and acetic acid to the biomass raw material was 1:3, and the obtained reaction solution was subjected to solid-liquid separation for the first time;

[0059] (2) The solid that is separated in the step (1) is added with a concentration of 80% formic acid and 10% acetic acid and 10% water f...

Embodiment 3

[0065] In this embodiment, first corn cobs (mass composition: moisture 6.12%, cellulose 35.19%, hemicellulose 32.1%, lignin 23.7%, other 2.95%) are broken, washed with water to remove dust and crushed to particle size It is 0.5-2cm.

[0066] The comprehensive utilization technique of lignocellulosic biomass described in this embodiment comprises the steps:

[0067] (1) After the 319.56Kg biomass raw material is pulverized and pretreated, use 60% formic acid and 40% acetic acid to carry out acid hydrolysis on the treated lignocellulosic biomass, control the reaction temperature at 150° C., and react for 180 minutes, The liquid-solid mass ratio of the mixed acid liquid of the formic acid and acetic acid to the biomass raw material is 1:10, and the obtained reaction liquid is subjected to solid-liquid separation for the first time;

[0068] (2) adding 60% formic acid and 40% acetic acid to the solid separated in step (1) for acidolysis (washing at 60° C. for 30 min), and perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com