A process for producing xylose from biomass raw materials

A biomass raw material, xylose technology, applied in the field of xylose production, can solve the problems of complex xylose extraction process, high acid-base energy consumption, etc., and achieve the effects of avoiding processing difficulties, no acid-base consumption, and reducing acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

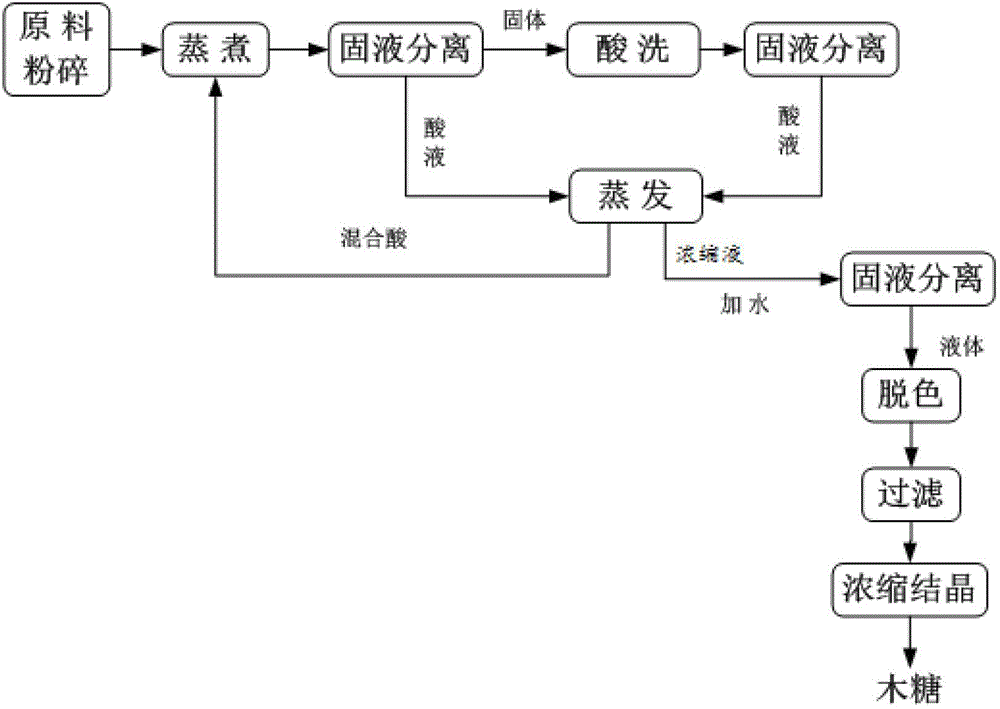

Image

Examples

Embodiment 1

[0042] First, the reeds (hemicellulose content 22.8%) are crushed, washed with water to remove dust and crushed to a particle size of 0.5-20 cm.

[0043] The comprehensive utilization process of biomass raw materials described in this embodiment comprises the following steps:

[0044] (1) After crushing the reed raw material for pretreatment, under the catalysis of hydrogen peroxide, use an organic acid solution with a total acid concentration of 80% to cook the treated biomass raw material, control the reaction temperature at 115°C, and react for 40 minutes. The solid-liquid mass ratio is 1:8, and the obtained reaction liquid is subjected to solid-liquid separation for the first time, wherein the mass ratio of acetic acid and formic acid forming the organic acid liquid is 4:1, and the mass ratio of hydrogen peroxide accounts for the 2% of the quality of biomass raw materials;

[0045] (2) Under the catalysis of hydrogen peroxide, the solid obtained from the first solid-liqui...

Embodiment 2

[0050] First, the wheat straw (hemicellulose content 31.4%) is crushed, washed with water to remove dust and crushed to a particle size of 0.5-20 cm.

[0051] The comprehensive utilization process of biomass raw materials described in this embodiment comprises the following steps:

[0052] (1) After crushing the wheat straw raw material for pretreatment, under the catalysis of hydrogen peroxide, use an organic acid solution with a total acid concentration of 60% to cook the processed raw material, control the reaction temperature at 100°C, and react for 60 minutes. The solid-liquid mass ratio is 1:15, and the obtained reaction solution is subjected to solid-liquid separation for the first time, wherein the mass ratio of acetic acid and formic acid forming the organic acid liquid is 3:1, and the mass ratio of hydrogen peroxide accounts for the 3% of the quality of biomass raw materials;

[0053] (2) Under the catalysis of hydrogen peroxide, the solid obtained from the first so...

Embodiment 3

[0058] In this embodiment, the biomass raw material is corn stalks. First, the corn stalks (with a hemicellulose content of 35.7%) are crushed, washed with water to remove dust and crushed to a particle size of 0.5-2 cm.

[0059] The comprehensive utilization process of biomass raw materials described in this embodiment comprises the following steps:

[0060] (1) After crushing the biomass straw raw material for pretreatment, under the catalysis of hydrogen peroxide, use an organic acid solution with a total acid concentration of 70% to cook the treated biomass raw material, and control the reaction temperature to 105°C. React for 50 minutes, the solid-liquid mass ratio is 1:30, and the obtained reaction liquid is subjected to solid-liquid separation for the first time, wherein the mass ratio of acetic acid and formic acid forming the organic acid liquid is 10:1, and the mass ratio of hydrogen peroxide Accounting for 5% of the mass of the biomass raw material;

[0061] (2) Un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com