Method for preparing water-insoluble fibroin nanometer microcrystal powder

A nano-crystallite, water-insoluble technology, applied in the field of preparing water-insoluble silk fibroin nano-crystallite powder, can solve the problems of difficult industrialization, difficult formation, and inaccessibility, so as to simplify the operation steps and processes, maintain Excellent structure and performance, the effect of unstable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A method for preparing water-insoluble silk fibroin nanocrystal powder, said preparation method comprising the following steps:

[0015] a the silk in 0.5wt% Na 2 CO 3 Boil in an aqueous solution for 40 minutes, wash and dry with deionized water to obtain silk fibroin fibers, vacuum-dry at a drying temperature of 50°C and a drying time of 12 hours, and grind the dried silk fibroin fibers into particles with an average particle size of ≤3 μm For silk fibroin powder, in addition to vacuum drying, other drying methods can also be used to dry the washed silk fibroin fibers, and the dried silk fibroin fibers can be ground by a ball mill or other methods to achieve the required particle size.

[0016] b. The silk fibroin powder with an average particle size ≤ 3 μm obtained in the step a is at room temperature according to the silk fibroin powder and H 2 SO 4 The weight ratio is 1:10~40 and mixed into silk fibroin powder suspension, wherein H 2 SO 4 The concentration of t...

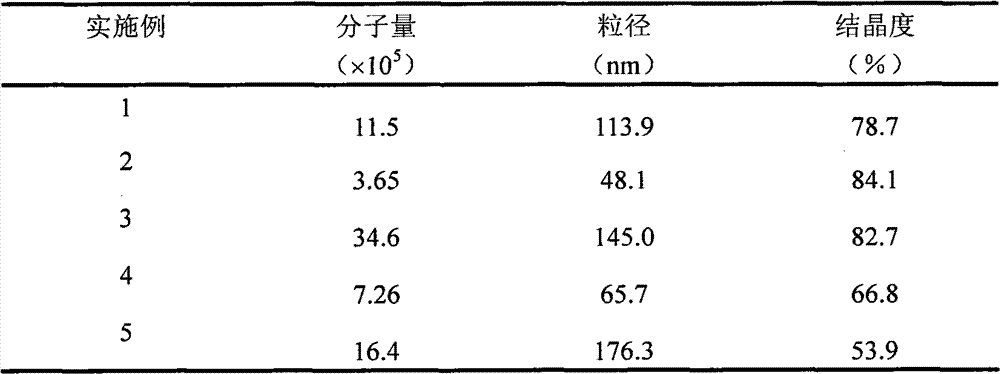

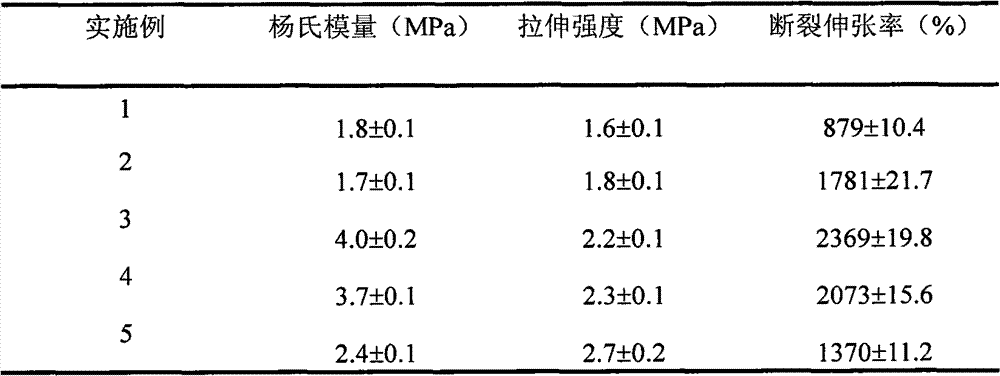

Embodiment 1

[0021] At room temperature, mix 2g of silk fibroin powder with an average particle size of ≤3μm and 30g of 70wt% H 2 SO 4 The solution was mixed into silk fibroin powder suspension, heated to 40°C, cooled to room temperature after mechanical stirring for 4 hours, neutralized with 20wt% NaOH solution, dialyzed with running water for 5 days and deionized water for 2 days, and then The centrifuge was centrifuged at 4000 rpm for 30 minutes, and finally, freeze-dried at -50° C. for 36 hours in a freeze dryer to obtain water-insoluble silk fibroin nanocrystal powder. The non-water-soluble silk fibroin nano-microcrystalline powder obtained under this acid hydrolysis condition was blended with water-based polyurethane in a ratio of 10:90 by weight, after vigorous stirring for 30 minutes, the blended solution was left to stand at room temperature for 10 minutes, and then pumped Vacuum degassing, pouring the above blended solution into a glass mold, leaving it at room temperature for 2...

Embodiment 2

[0023] At room temperature, mix 2g of silk fibroin powder with an average particle size ≤ 3 μm and 120g of 50wt% H 2 SO 4 The solution was mixed into silk fibroin powder suspension, heated to 60°C, cooled to room temperature after mechanical stirring for 6 hours, neutralized with 20wt% NaOH solution, dialyzed with running water for 5 days and deionized water for 2 days, and then The centrifuge was centrifuged at 4000 rpm for 30 minutes, and finally, freeze-dried at -50° C. for 36 hours in a freeze dryer to obtain water-insoluble silk fibroin nanocrystal powder. The non-water-soluble silk fibroin nano-microcrystalline powder obtained under this acid hydrolysis condition is blended with water-based polyurethane in a weight ratio of 10:90, after vigorously stirring for 30 minutes, the blended solution is left to stand at room temperature for 10 minutes, and then Vacuumizing and defoaming, pouring the above blended solution into a glass mold, leaving it at room temperature for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com