Platinum alloy electrode and method for producing the same

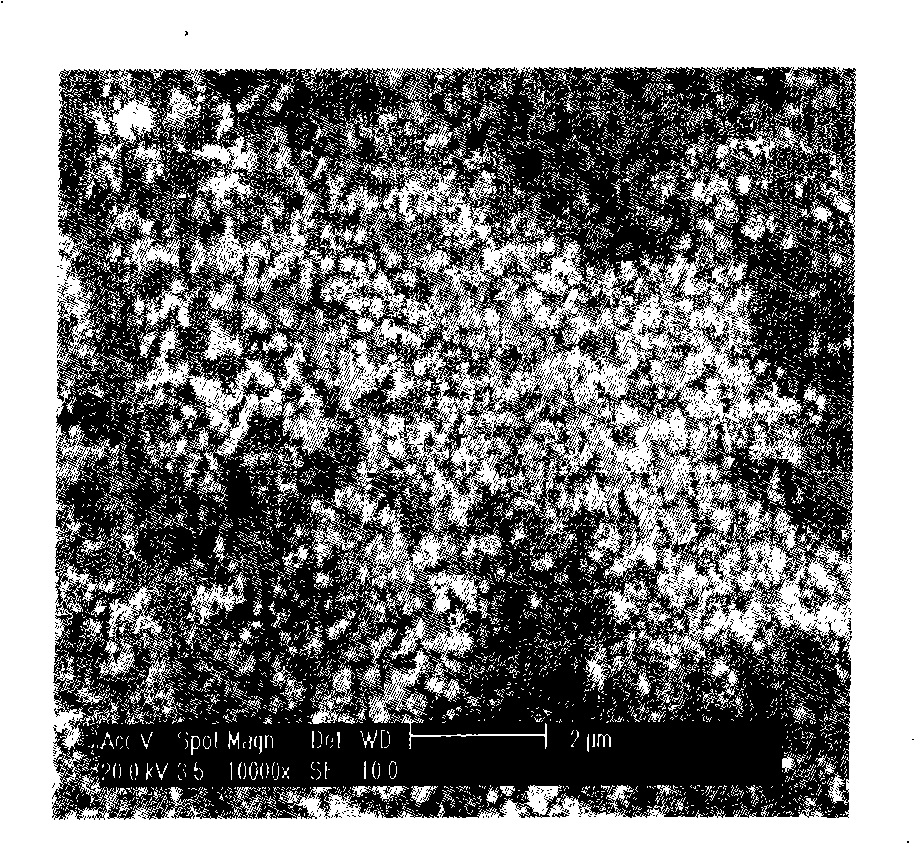

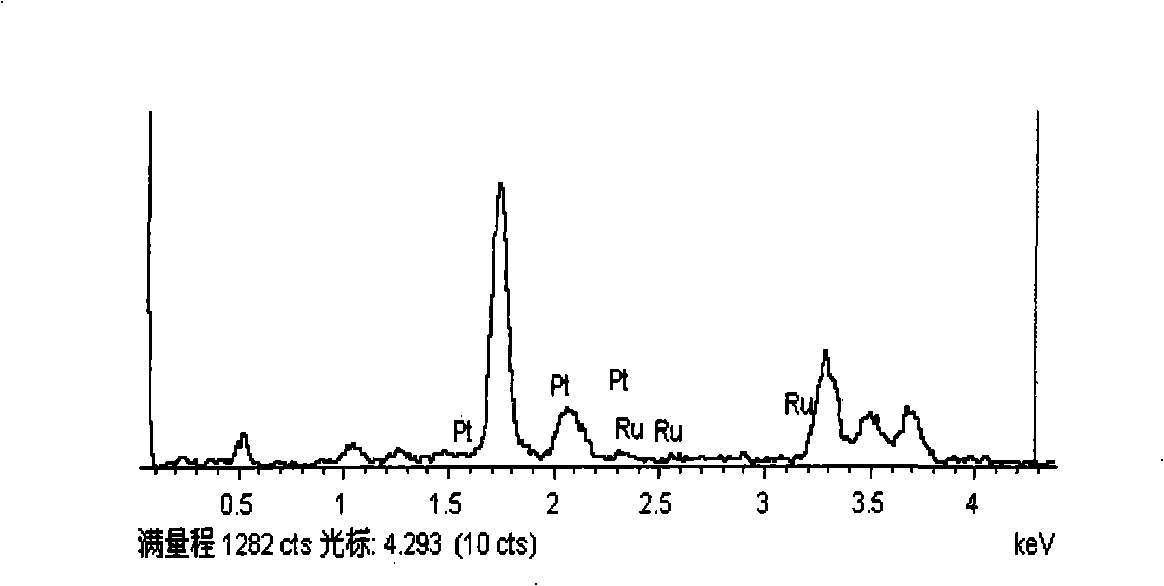

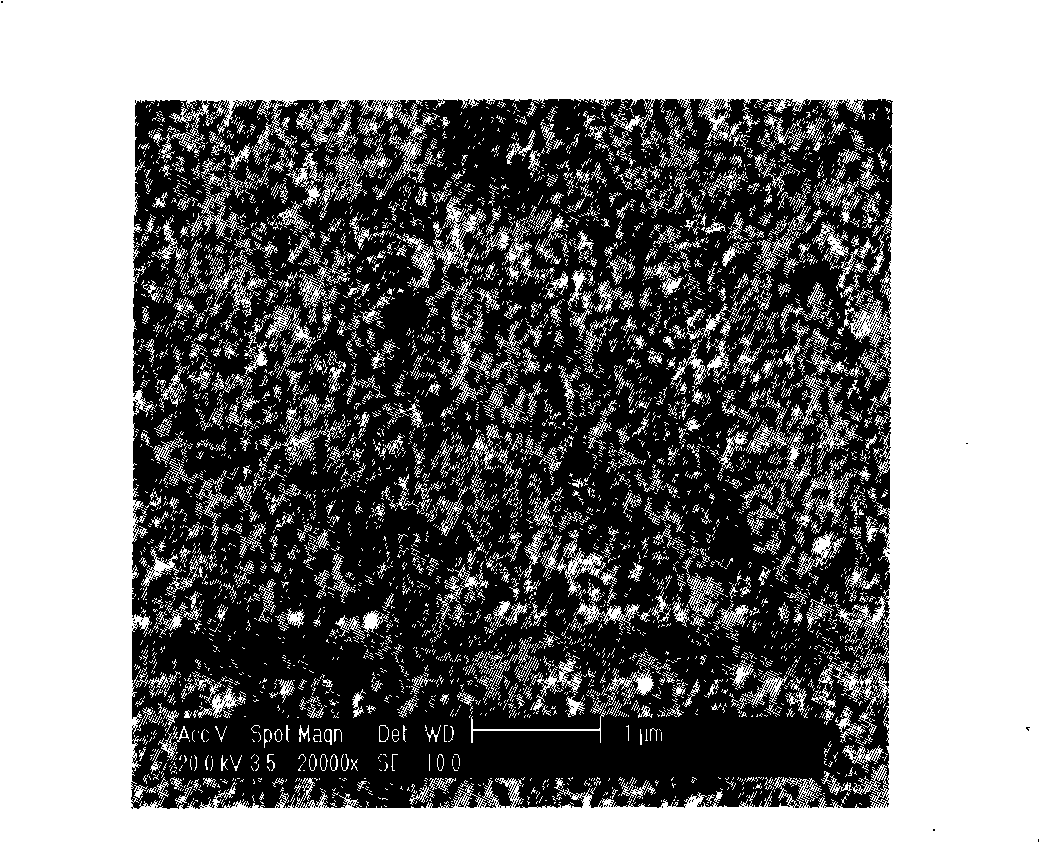

A platinum alloy and electrode technology, applied in the field of dye-sensitized solar cells, can solve the problems of Pt dissolution, poisoning, and high electrode cost, and achieve the effects of stable performance, uniform distribution and dense surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Prepare 100ml H 2 PtCl 6 and RuCl 3 mixed aqueous solution, H 2 PtCl 6 The concentration is 1.93×10 -3 mol L -1 , RuCl 3 The concentration is 2.7×10 -3 mol L -1 ;

[0023] (2) 0.5g solid (NH 4 ) 2 HPO 4 and 1.5 g solid Na 2 HPO 4 Add to the above mixed solution in turn, and stir at room temperature;

[0024] (3) Heat the above mixed solution to a near-boiling state, until the smell of ammonia gradually disappears, and the solution changes from yellow to colorless, add 5% NaOH (or Na 2 CO 3 Saturated aqueous solution) the pH value of the solution was adjusted to 8.

[0025] (4) Dilute the solution obtained in the step (3) to 100ml, and conduct electrodeposition with the ITO conductive glass as the cathode. Current density 25mA·cm -2 , the electrodeposition time is 1.5 minutes, and the electrolyte temperature is 70°C;

[0026] (5) In the step (4), the commercial ITO conductive glass is soaked in 0.5% NaOH aqueous solution for 5 hours before use, the...

Embodiment 2

[0031] (1) Prepare 100ml H 2 PtCl 6 and RuCl 3 mixed aqueous solution, H 2 PtCl 6 The concentration is 0.9×10 -3 mol L -1 , RuCl 3 The concentration is 1.5×10 -3 mol L -1 ;

[0032] (2) 0.6g solid (NH 4 ) 2 HPO 4 and 2.0 g solid Na 2 HPO 4 Add to the above mixed solution in turn, and stir at room temperature;

[0033](3) The above-mentioned mixed solution is heated to a near-boiling state until the smell of ammonia gradually disappears, and the solution changes from yellow to colorless, adding Na 2 CO 3 The saturated aqueous solution was adjusted to pH 7.

[0034] (4) Dilute the solution obtained in the step (3) to 100ml, and conduct electrodeposition with the ITO conductive glass as the cathode. Current density 15mA·cm -2 , electrodeposition time 2.0 minutes, electrolyte temperature 80 ℃;

[0035] (5) In the step (4), the commercial ITO conductive glass is soaked with 1% NaOH aqueous solution for 3 hours before use, then washed with distilled water, acetone...

Embodiment 3

[0039] (1) Prepare 100ml H 2 PtCl 6 and RuCl 3 mixed aqueous solution, H 2 PtCl 6 The concentration is 2×10 -3 mol L -1 , RuCl 3 The concentration is 3.5×10 -3 mol L -1 ;

[0040] (2) 0.55g solid (NH 4 ) 2 HPO 4 and 1.7 g solid Na 2 HPO 4 Add to the above mixed solution in turn, and stir at room temperature;

[0041] (3) The above-mentioned mixed solution is heated to a near-boiling state until the smell of ammonia gradually disappears, and the solution changes from yellow to colorless, adding Na 2 CO 3 Adjust the pH value of the saturated aqueous solution to 7.5.

[0042] (4) Dilute the solution obtained in the step (3) to 100ml, and conduct electrodeposition with the ITO conductive glass as the cathode. Current density 30mA·cm -2 , the electrodeposition time is 1.0 minutes, and the electrolyte temperature is 75°C;

[0043] (5) In the described step (4), the commercial ITO conductive glass is soaked with 2% NaOH aqueous solution for 2 hours before use, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com