Antioxidant fiber-reinforced silicon-boron-nitrogen composite material and preparation method and application thereof

A fiber-reinforced and composite material technology, which is applied in the field of composite materials, can solve the problems of insufficient surface structure and poor oxidation resistance, and achieve the effects of good interface bonding, good high temperature resistance and oxidation resistance, and uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

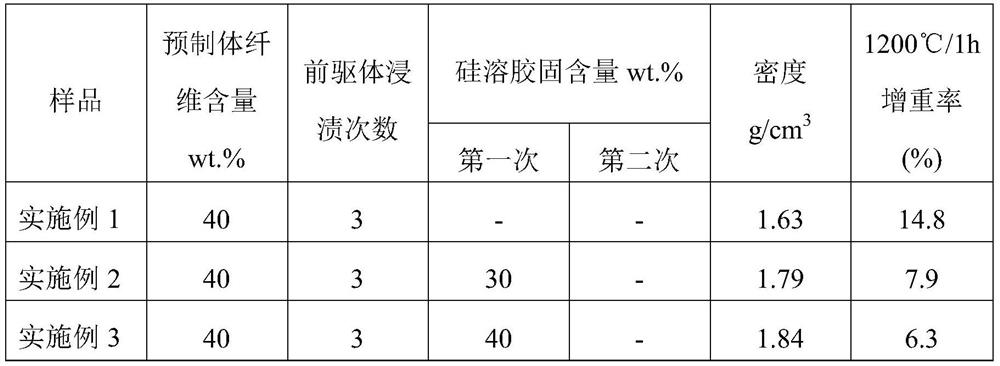

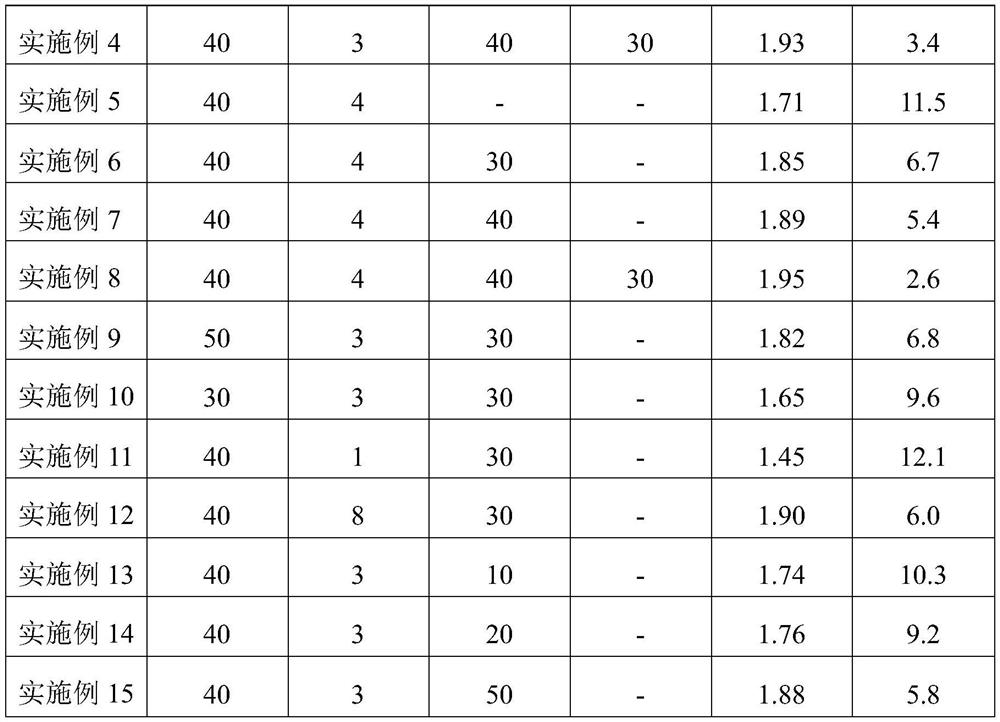

Embodiment 1

[0057] The silicon nitride fiber is processed into a preform with a fiber volume content of 40% by weaving.

[0058] Then the precursor is used to impregnate the preform by vacuum impregnation method, and then the crosslinking and curing reaction under nitrogen atmosphere (220°C for 10h) and the cracking reaction under ammonia atmosphere (900°C for 3h) are carried out to make the matrix and the preform The cross-links are gradually integrated. Repeat the immersion, curing and cracking of the precursor three times to obtain the green body.

[0059] Finally, the green body is impregnated by vacuum impregnation method without using silica sol, and the density at room temperature is 1.63g / cm 3 , A composite material with a weight gain rate of 14.8% after oxidation treatment in an air atmosphere at 1200°C for 1 hour.

Embodiment 2

[0061] The silicon nitride fiber is processed into a preform with a fiber volume content of 40% by weaving.

[0062] Then use the precursor to impregnate the preform by vacuum impregnation method, and then carry out the crosslinking and curing reaction under nitrogen atmosphere (220°C for 10h) and the cracking reaction under ammonia atmosphere (900°C for 3h), so that the gap between the matrix and the preform is Cross-linking occurs and gradually merges into one. Repeat the immersion, curing and cracking of the precursor three times to obtain the green body.

[0063] Finally, the silica sol with a solid content of 30wt.% is used to impregnate the green body by vacuum impregnation, the surface of the green body is filled and densified, and then dried (after 6 hours at 80°C, and then adjusted to 160°C for 3 hours) ), the density at normal temperature is 1.79g / cm 3 , A composite material with a weight gain rate of 7.9% after oxidation treatment in an air atmosphere at 1200°C fo...

Embodiment 3

[0065] The silicon nitride fiber is processed into a preform with a fiber volume content of 40% by weaving.

[0066] Then use the precursor to impregnate the preform by vacuum impregnation method, and then carry out the crosslinking and curing reaction under nitrogen atmosphere (10h at 220°C) and the cracking reaction under ammonia atmosphere (3h at 900°C), so that the gap between the matrix and the preform is Cross-linking occurs and gradually merges into one. Repeat the immersion, curing and cracking of the precursor three times to obtain the green body.

[0067] Finally, the silica sol with a solid content of 40wt.% is used to impregnate the green body by vacuum impregnation method, the surface of the green body is filled and densified, and then dried (6h at 80°C and then adjusted at 160°C for 3h), Get a density of 1.84g / cm at room temperature 3 , A composite material with a weight gain rate of 6.3% after oxidation treatment at 1200°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com