Method for preparing recycled aggregate pervious concrete by using aqueous capillary crystalline solution

A permeable concrete and recycled aggregate technology, applied in the field of concrete, can solve the problems of low concrete strength, poor water permeability, and small porosity, and achieve the effects of increasing compactness and compressive strength, increasing cohesion, and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

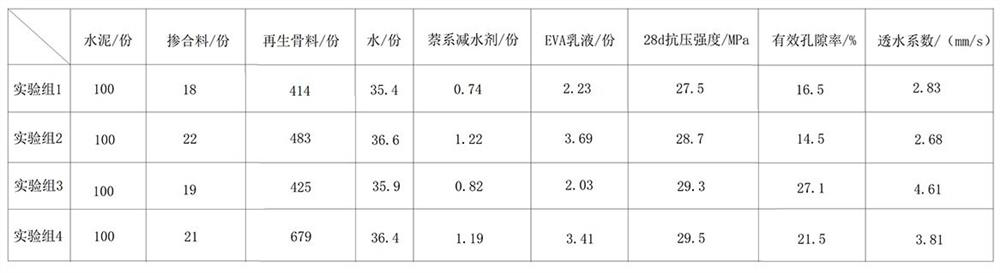

[0026] Example 1: This example relates to a method for preparing recycled aggregate permeable concrete using an aqueous osmotic crystallization solution, such as figure 1 As shown, the mass ratio of raw materials of recycled aggregate permeable concrete in experimental group 1 is: 100 parts of cement, 18 parts of admixture, 414 parts of recycled aggregate, 35.4 parts of water, 0.74 parts of naphthalene-based water reducer, EVA (ethylene -vinyl acetatecopolymer, ethylene-vinyl acetate copolymer) emulsion 2.23 parts, its method comprises the following steps:

[0027] Step (1): Soak the air-dried recycled aggregate in the water-based osmotic crystallization solution, filter after soaking for 3 hours, take it out and place it on a plastic plate in the curing room for 1 day. Among them, the recycled aggregate is the aggregate with a particle size range of 4.75-26.5mm after the waste concrete is crushed, sieved and washed with water; the stacked porosity of the recycled aggregate is...

Embodiment 2

[0031] Embodiment 2: This embodiment relates to a method for preparing recycled aggregate permeable concrete using an aqueous osmotic crystallization solution, such as figure 1 As shown, the mass ratio of raw materials for recycled aggregate permeable concrete in experimental group 2 is: 100 parts of cement, 22 parts of admixture, 483 parts of recycled aggregate, 36.6 parts of water, 1.22 parts of naphthalene-based water reducer, and 3.69 parts of EVA emulsion The method includes the following steps:

[0032]Step (1): Soak the air-dried recycled aggregate in the water-based osmotic crystallization solution, filter after soaking for 3 hours, take it out and place it on a plastic plate in the curing room for 1 day. Among them, the recycled aggregate is the aggregate with a particle size range of 4.75-26.5mm after the waste concrete has been crushed, sieved and washed with water; the water-based osmotic crystallization solution is composed of 100% sodium silicate, catalysts and a...

Embodiment 3

[0036] Embodiment 3: This embodiment relates to a method for preparing recycled aggregate permeable concrete using an aqueous osmotic crystallization solution, such as figure 1 As shown, the mass ratio of raw materials for recycled aggregate permeable concrete in experimental group 3 is: 100 parts of cement, 19 parts of admixture, 425 parts of recycled aggregate, 35.9 parts of water, 0.82 parts of naphthalene-based superplasticizer, and 2.03 parts of EVA emulsion The method includes the following steps:

[0037] Step (1): Soak the air-dried recycled aggregate in the water-based osmotic crystallization solution, filter after soaking for 3 hours, take it out and place it on a plastic plate in the curing room for 1 day. Among them, the recycled aggregate is the aggregate with a particle size range of 4.75-26.5mm after the waste concrete has been crushed, sieved and washed with water; the water-based osmotic crystallization solution is composed of 100% sodium silicate, catalysts a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com