Electrostatic filter cotton with improved performance and preparation method and application thereof

A filter cotton and electrostatic technology, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of high cost pressure of electrostatic filter cotton, slow growth of filtration efficiency with gram weight, and limited wide-scale application. Achieve the effect of low weight, easy operation, and expand the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation method of the performance-improved electrostatic filter cotton of the present embodiment comprises the following steps:

[0066] Step 1: Prepare unrolled polypropylene and acrylic two-component electrostatic filter cotton

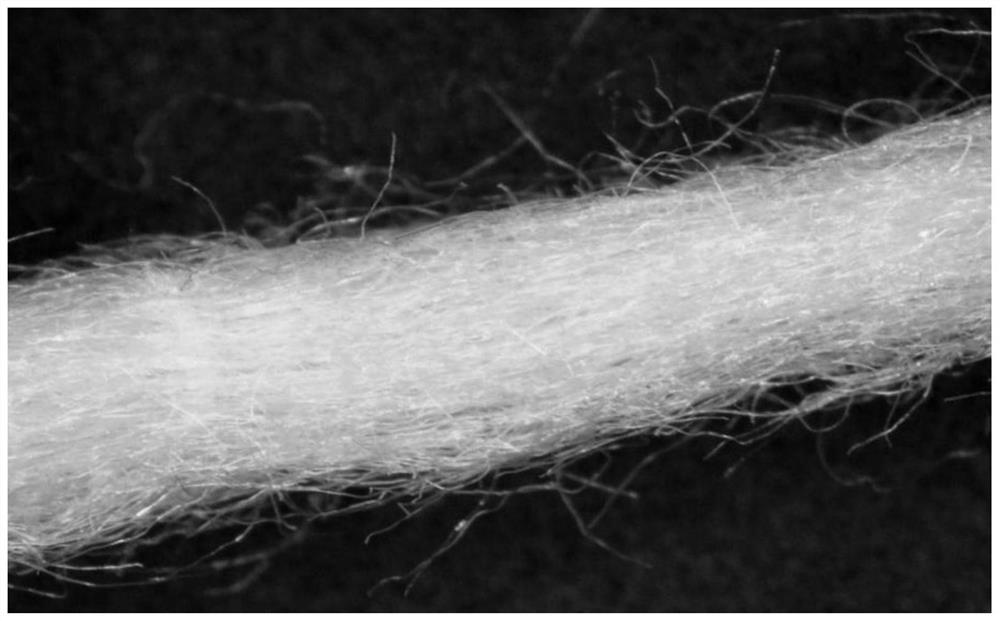

[0067] Get the polypropylene fiber of prior art and the two-component electrostatic filter cotton of acrylic fiber, its micrograph, as figure 1 shown. Unwinding under slight tension with a tensile strength of 0.1 N / cm to obtain unrolled polypropylene and acrylic two-component electrostatic filter cotton.

[0068] Step 2: Preparation of hot-pressed polypropylene and acrylic two-component electrostatic filter cotton

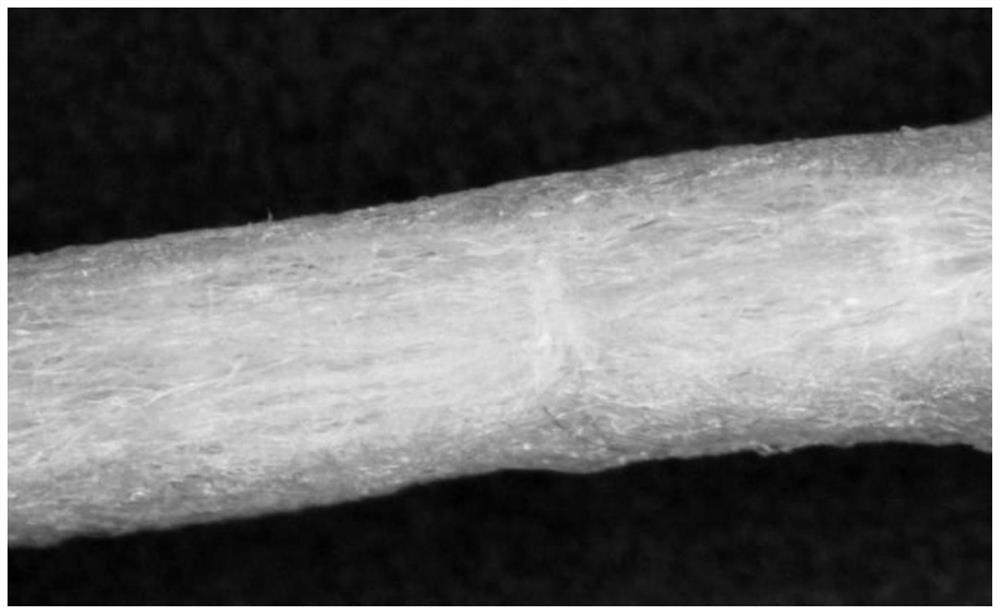

[0069] After correcting the deviation of the unrolled polypropylene and acrylic two-component electrostatic filter cotton obtained in step 1, hot pressing is carried out. The normal pressure of the hot pressing is 0.02MPa, the temperature is 70°C, and the hot pressing time is 5s. Two-component electrostatic filter cotto...

Embodiment 2

[0084] The preparation method of the performance-improved electrostatic filter cotton of the present embodiment comprises the following steps:

[0085] Step 1: Prepare unrolled polypropylene fiber electrostatic filter cotton

[0086] Take the polypropylene fiber electrostatic filter cotton, and use a tension strength of 1N / cm to carry out micro-tension unwinding to obtain the unrolled polypropylene fiber electrostatic filter cotton.

[0087] Step 2: Prepare hot-pressed polypropylene fiber electrostatic filter cotton

[0088] After rectifying the unrolled polypropylene fiber obtained in step 1, perform hot pressing, the normal pressure of the hot pressing is 25MPa, the temperature is 120°C, the hot pressing time is 50s, and the polypropylene fiber after hot pressing is electrostatically filtered cotton.

[0089] Step 3: Prepare electrostatic filter cotton coated with hot melt adhesive on one side

[0090] Take the PES hot-melt adhesive film and laminate it with one side of the...

Embodiment 3

[0097] The preparation method of the performance-improved polyester electrostatic filter cotton of the present embodiment comprises the following steps:

[0098] Step 1: Prepare unrolled polyester electrostatic filter cotton

[0099] Take the polyester electrostatic filter cotton, and use a tension strength of 2N / cm to carry out micro-tension unwinding to obtain the unrolled polyester electrostatic filter cotton.

[0100] Step 2: Prepare hot-pressed electrostatic filter cotton

[0101] After correcting the deviation of the unrolled polyester electrostatic filter cotton obtained in step 1, perform hot pressing, the normal pressure of the hot pressing is 50MPa, the temperature is 180°C, and the hot pressing time is 120s, and the polyester electrostatic filter cotton after hot pressing is obtained. filter sponge.

[0102] Step 3: Prepare electrostatic filter cotton coated with hot melt adhesive on one side

[0103] Take the polyester with a viscous open time of 3s-120s, heat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com