Superconducting graphite electrode nano antioxidant and preparation method thereof

A graphite electrode and anti-oxidant technology, which is applied in electric heating devices, electrical components, heating through discharge, etc., can solve the problems of insufficient anti-oxidation properties of antioxidants, and achieve the effects of improving anti-oxidation performance, prolonging service life, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

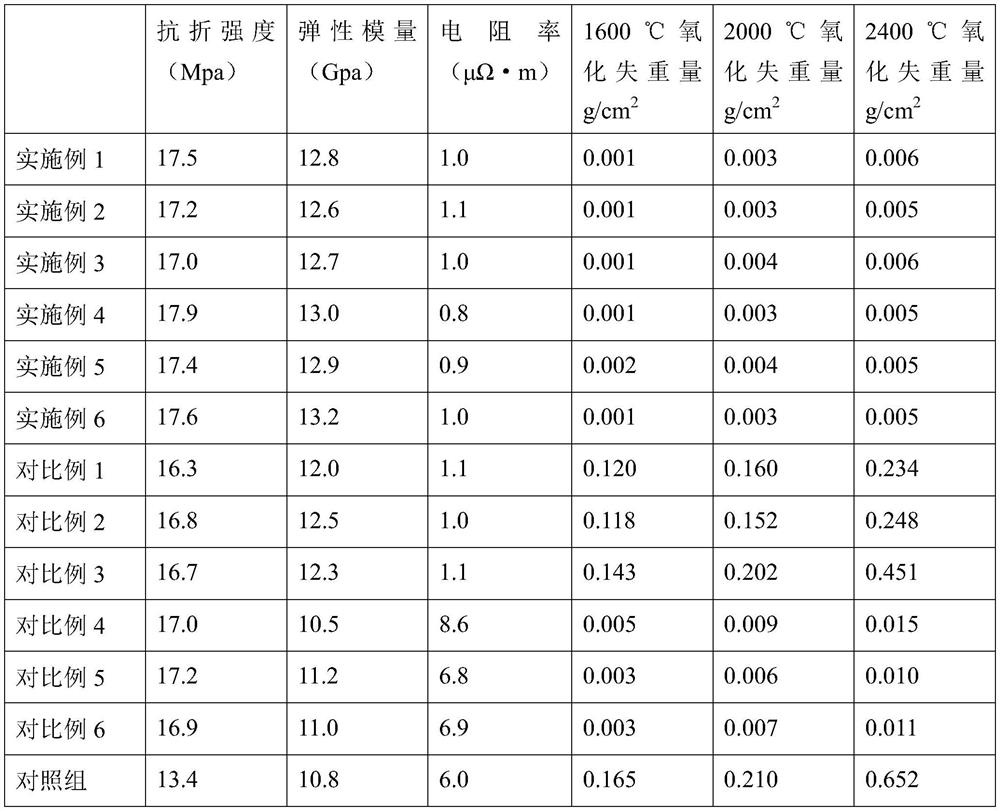

Examples

Embodiment 1

[0023] A preparation method of superconducting graphite electrode nano antioxidant, comprising the following steps:

[0024] A, prepare 95 parts of water, 30 parts of ceramic powder, 22 parts of graphene, 20 parts of polyethylene glycol, 10 parts of stabilizer, 8 parts of antioxidant additives, 12 parts of polyvinyl alcohol, and take each component for later use; Oxidation aids include calcium boride, vanadium diboride, and sodium dihydrogen phosphate with a mass ratio of 2:1:1; stabilizers include meglumine and zirconium nitride with a mass ratio of 1.2:1; ceramic powder consists of the following weight The composition of parts: 15 parts of cerium oxide, 11 parts of titanium dioxide, 12 parts of aluminum oxide;

[0025] B. Grinding the ceramic powder weighed in step A to a particle size of 80nm, adding polyethylene glycol to obtain a ceramic powder slurry;

[0026] C, adding step B ceramic powder slurry and graphene into water to obtain a premixed solution;

[0027] D. Add ...

Embodiment 2

[0029] A preparation method of superconducting graphite electrode nano antioxidant, comprising the following steps:

[0030] A, prepare 80 parts of water, 40 parts of ceramic powder, 20 parts of graphene, 25 parts of polyethylene glycol, 6 parts of stabilizer, 10 parts of antioxidant additives, 10 parts of polyvinyl alcohol, and take each component for later use; Oxidation aids include calcium boride, vanadium diboride, and sodium dihydrogen phosphate with a mass ratio of 2:1.2:1; stabilizers include meglumine and zirconium nitride with a mass ratio of 1:1; ceramic powder consists of the following weight The composition of parts: 20 parts of cerium oxide, 10 parts of titanium dioxide, 14 parts of aluminum oxide;

[0031] B. Grinding the ceramic powder weighed in step A to a particle size of 50nm, adding polyethylene glycol to obtain a ceramic powder slurry;

[0032] C, adding step B ceramic powder slurry and graphene into water to obtain a premixed liquid;

[0033] D. Add an...

Embodiment 3

[0035] A preparation method of superconducting graphite electrode nano antioxidant, comprising the following steps:

[0036] A, prepare 100 parts of water, 20 parts of ceramic powder, 25 parts of graphene, 10 parts of polyethylene glycol, 12 parts of stabilizer, 5 parts of antioxidant additives, 15 parts of polyvinyl alcohol, and take each component for later use; Oxidation aids include calcium boride, vanadium diboride, and sodium dihydrogen phosphate with a mass ratio of 2:0.8:1; stabilizers include meglumine and zirconium nitride with a mass ratio of 1.32:1; ceramic powder consists of the following weight The composition of parts: 10 parts of cerium oxide, 15 parts of titanium dioxide, 5 parts of aluminum oxide;

[0037] B. Grinding the ceramic powder weighed in step A to a particle size of 100nm, adding polyethylene glycol to obtain a ceramic powder slurry;

[0038] C, adding step B ceramic powder slurry and graphene into water to obtain a premixed liquid;

[0039] D. Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com