Plating solution for plating nickel and phosphorus on surface of magnesium lithium alloy and low-temperature plating method

A magnesium-lithium alloy, surface chemistry technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as surface corrosion, surface pitting corrosion of magnesium-lithium alloy, and achieve uniform and dense coating and good appearance , the effect of bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

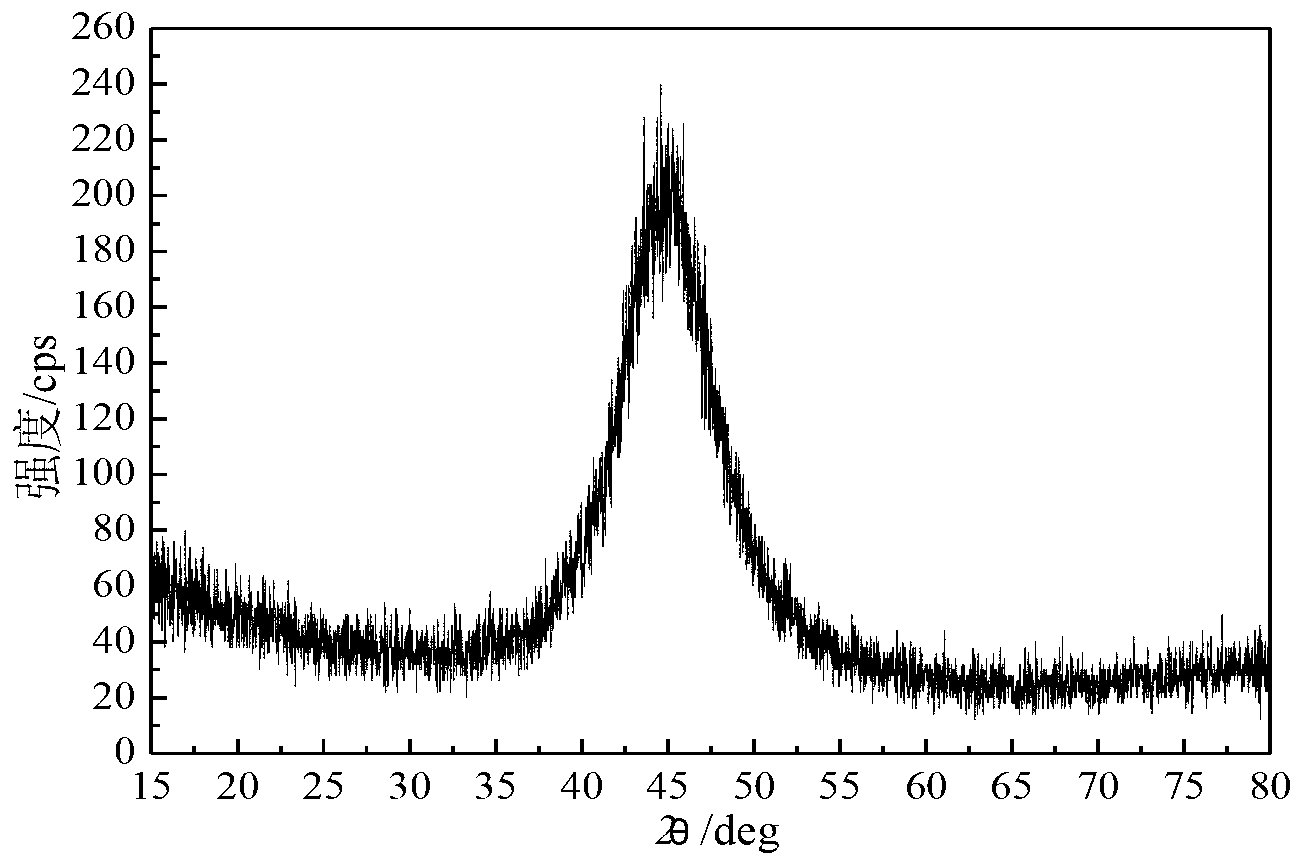

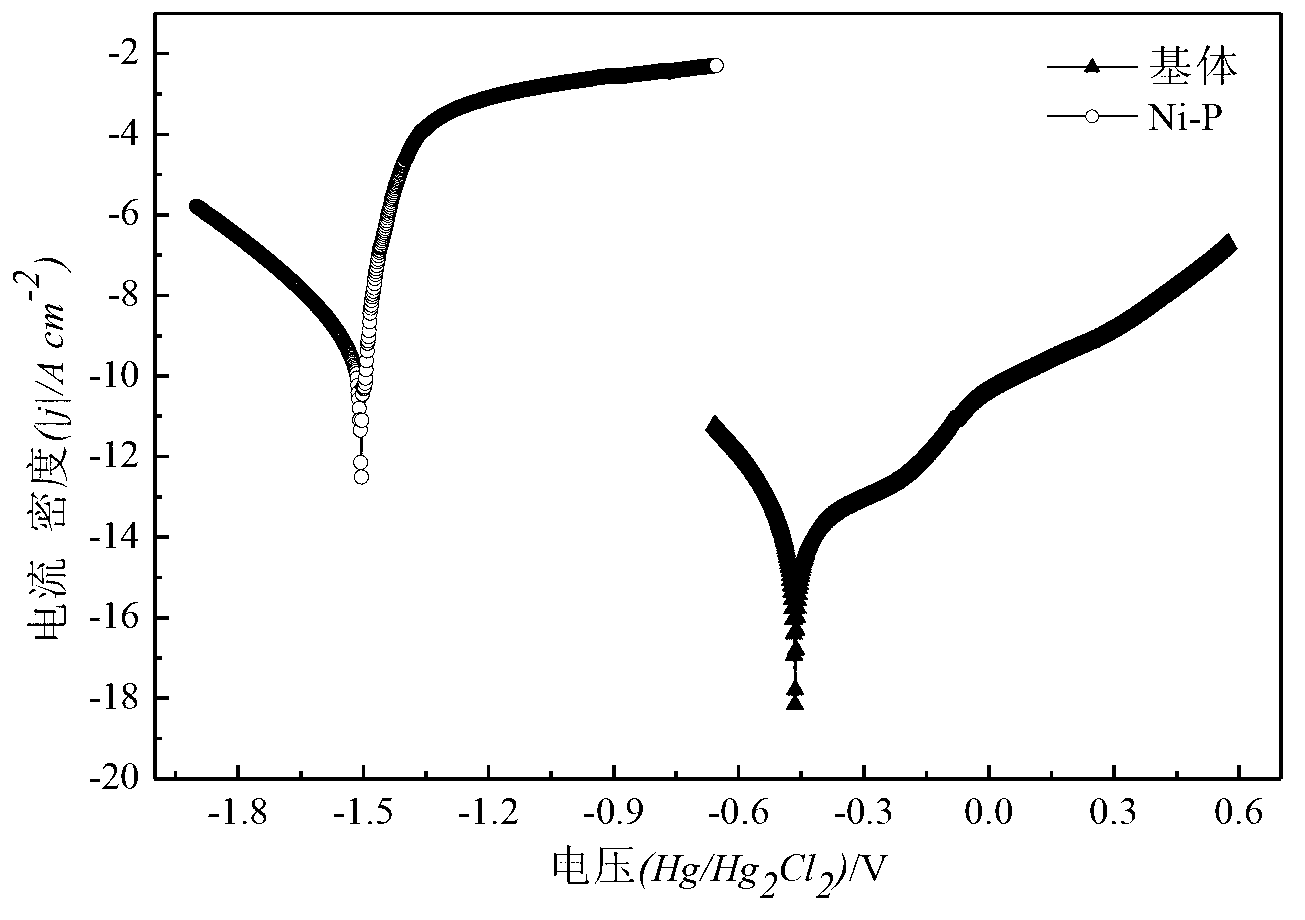

Image

Examples

Embodiment 1

[0037] Step 1, weigh the following components respectively: main salt: nickel sulfate 25g / L, reducing agent: sodium hypophosphite 27g / L, complexing agent: citric acid 8g / L, corrosion inhibitor: ammonium hydrogen fluoride 10g / L, Accelerator: hydrofluoric acid 12mL / L, stabilizer: thiourea 2mg / L, brightener: sodium lauryl sulfate 5mg / L, after mixing the above components evenly, use ammonia water to adjust the pH value to 5.5 to obtain magnesium Lithium alloy surface electroless nickel phosphorus plating solution;

[0038] Step 2, the surface of the Mg-8%Li-based magnesium-lithium alloy workpiece near the eutectic point is sequentially polished with 400#, 800# and 1200# metallographic sandpaper to remove stains and plaques on the surface, making the surface smooth and without obvious scratches;

[0039] Step 3, ultrasonically cleaning the Mg-8%Li-based magnesium-lithium alloy workpiece after surface polishing in acetone for 8 minutes to remove oil stains on the surface of the sub...

Embodiment 2

[0049] Step 1, weigh the following components respectively: main salt: nickel sulfate 25g / L, reducing agent: sodium hypophosphite 27g / L, complexing agent: citric acid 8g / L, corrosion inhibitor: ammonium hydrogen fluoride 10g / L, Accelerator: hydrofluoric acid 12mL / L, stabilizer: thiourea 2mg / L, brightener: sodium lauryl sulfate 5mg / L, after mixing the above components evenly, adjust the pH value to 6 with ammonia water to obtain magnesium Lithium alloy surface electroless nickel phosphorus plating solution;

[0050] Step 2, the surface of the Mg-4%Li-based magnesium-lithium alloy workpiece is sequentially polished with 200#, 800# and 1200# metallographic sandpaper to remove stains and plaques on the surface, making the surface smooth and free of obvious scratches;

[0051] Step 3, ultrasonically cleaning the hypoeutectic Mg-4%Li-based magnesium-lithium alloy workpiece after surface polishing in acetone for 5 minutes to remove oil stains on the surface of the substrate, and then...

Embodiment 3

[0058] Step 1, weigh the following components respectively: main salt: nickel sulfate 27g / L, reducing agent: sodium hypophosphite 30g / L, complexing agent: citric acid 7g / L, corrosion inhibitor: ammonium hydrogen fluoride 9g / L, Accelerator: hydrofluoric acid 10mL / L, stabilizer: thiourea 1.5mg / L, brightener: sodium lauryl sulfate 5mg / L, after mixing the above components evenly, adjust the pH value to 6 with ammonia water to obtain Electroless nickel-phosphorus plating solution on the surface of magnesium-lithium alloy;

[0059] Step 2, the surface of the Mg-12%Li-based magnesium-lithium alloy workpiece is polished sequentially with 400#, 1200# and 2000# metallographic sandpaper to remove stains and plaques on the surface, making the surface smooth and free of obvious scratches;

[0060] Step 3, the Mg-12%Li-based magnesium-lithium alloy workpiece after surface grinding is ultrasonically cleaned in acetone for 3 minutes to remove the oil stain on the surface of the substrate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com