Weaving wicker modifying treatment method

A treatment method and wicker technology, applied in wood treatment, wood treatment details, reed/straw treatment, etc., can solve the problems of being susceptible to UV infection, intolerance to moisture and drying, and reduced mechanical properties, and achieve enhanced UV resistance. capacity, improved absorbance, mechanical properties and improved weatherability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

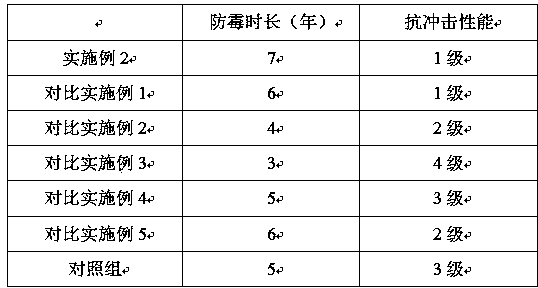

Examples

Embodiment 1

[0027] A method for modifying wicker for weaving, comprising the following steps:

[0028] (1) Wicker pretreatment:

[0029] a. Take the mud from the paddy field where rice has been planted for a long time, stir and mix the mud and tap water until the water content is 35%, and get the paste;

[0030] b. Apply the paste obtained in operation a to the surface of the peeled wicker with a coating thickness of 8mm. After the coating is completed, place the wicker in an environment of 36°C for 7 hours;

[0031] c. Wash the wicker surface with tap water after b treatment, remove the paste on the wicker, and then place it in an environment of 60°C for drying until the surface moisture content is 28%;

[0032] (2) Soaking treatment:

[0033] Soak the wicker obtained after pretreatment in step (1) in the treatment solution, and treat it with ultrasonic waves of a specific frequency while soaking. After soaking for 2 hours, take out the wicker and drain it for later use;

[0034] (3) ...

Embodiment 2

[0045] A method for modifying wicker for weaving, comprising the following steps:

[0046] (1) Wicker pretreatment:

[0047] a. Get the mud from the paddy field where rice has been planted for a long time, stir and mix the mud and tap water until the water content is 36%, and get the paste;

[0048] b. Apply the paste obtained in operation a to the surface of the peeled wicker with a thickness of 9mm. After the coating is completed, place the wicker in an environment of 38°C for 8 hours;

[0049] c. Wash the surface of the wicker with tap water after b treatment, remove the paste on the wicker, and then place it in an environment of 65°C for drying until the surface moisture content is 31%;

[0050] (2) Soaking treatment:

[0051] Soak the wicker obtained after pretreatment in step (1) in the treatment solution, and treat it with ultrasonic waves of a specific frequency while soaking. After soaking for 2.5 hours, take out the wicker and drain it for later use;

[0052] (3) Ir...

Embodiment 3

[0063] A method for modifying wicker for weaving, comprising the following steps:

[0064] (1) Wicker pretreatment:

[0065] a. Get the mud from the paddy field where rice has been planted for a long time, stir and mix the mud and tap water until the water content is 37%, and get the paste;

[0066] b. Apply the paste obtained in operation a to the surface of the peeled wicker with a thickness of 10mm. After the coating is completed, place the wicker in an environment of 40°C for 9 hours;

[0067] c. Wash the wicker surface with tap water after b treatment, remove the paste on the wicker, and then place it in an environment of 70°C for drying until the surface moisture content is 34%;

[0068] (2) Soaking treatment:

[0069] Soak the wicker obtained after pretreatment in step (1) in the treatment solution, and treat it with ultrasonic waves of a specific frequency while soaking. After soaking for 3 hours, take out the wicker and drain it for later use;

[0070] (3) Irradiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com