Negative electrode material for high-specific-power lithium ion battery as well as preparation and application thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of low initial efficiency and achieve high rate performance, high initial efficiency, and high comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

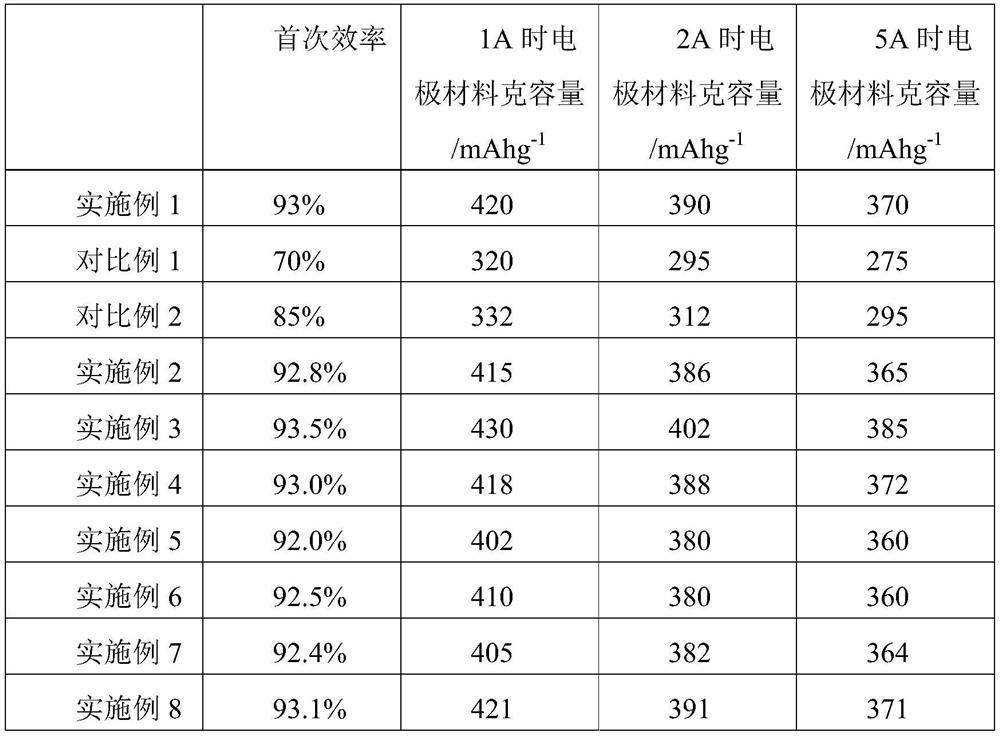

[0025] Mix fluorinated graphene (F:C=0.2) and hard carbon into a dopamine tris buffer solution with a pH of 9.4 according to a mass ratio of 2.5:97.5, and a dopamine concentration of 2%. After stirring for 3 hours, filter and wash until the pH= 7 until neutral, dry, and calcined at a temperature of 1000°C in an argon atmosphere for 24 hours, and cool naturally to prepare the electrode material. The F:C molar ratio in the fluorinated graphene is 0.3. The fluorinated graphene accounts for 10% of the total weight of the composite negative electrode material, which is used to further test the first efficiency and rate performance, which are recorded in Table 1.

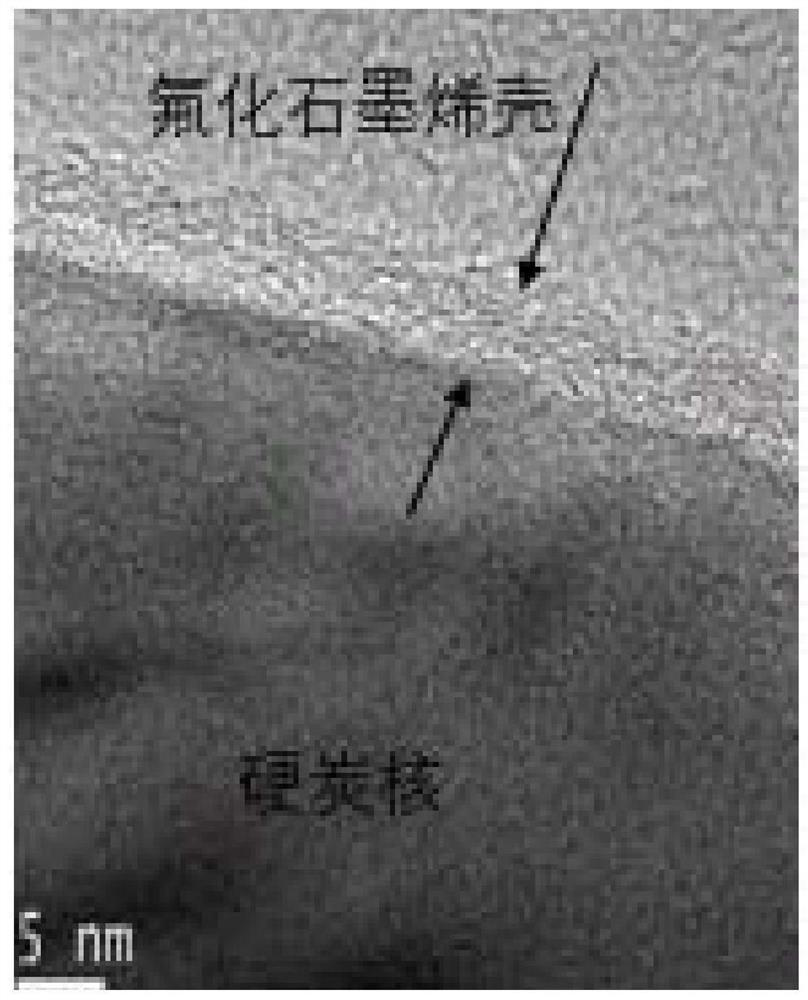

[0026] figure 1 Electron micrograph for the negative electrode material prepared in Example 1. It can be seen from the figure that the negative electrode material of the present invention uses fluorinated graphene as the shell and hard carbon as the core. The structure of hard carbon in the negative electrode material i...

Embodiment 2

[0032] Mix fluorinated graphene (F:C=0.1) and hard carbon into a dopamine tris buffer solution with a pH of 9.2 at a mass ratio of 5:95, and a dopamine concentration of 1.5%. After stirring for 3 hours, filter and wash until the pH= 7 until neutral, dry, and calcined at a temperature of 1200°C in an argon atmosphere for 36 hours, and cool naturally to prepare the electrode material. The F:C molar ratio in the fluorinated graphene is 0.4. The fluorinated graphene accounts for 10% of the total weight of the composite negative electrode material, which is used to further test the first efficiency and rate performance, which are recorded in Table 1.

[0033] The hard carbon structure in the negative electrode material is characterized by interlayer spacing in the range of 0.40nm. The fluorinated graphene sheet has 6 layers, and the thickness of the shell composed of fluorinated graphene is 150nm.

Embodiment 3

[0035] Mix fluorinated graphene (F:C=0.5) and hard carbon into a dopamine tris buffer solution with a pH of 9.4 according to a mass ratio of 2.5:97.5, and a dopamine concentration of 2%. After stirring for 3 hours, filter and wash until the pH= 7 until neutral, dry, and calcined at a temperature of 1000°C in an argon atmosphere for 24 hours, and cool naturally to prepare the electrode material. The F:C molar ratio in the fluorinated graphene is 0.5. The fluorinated graphene accounts for 10% of the total weight of the composite negative electrode material. For further testing the first efficiency and rate performance, recorded in Table 1.

[0036] The hard carbon structure in the negative electrode material is characterized by interlayer spacing in the range of 0.40nm. The fluorinated graphene sheet is 4 layers, and the thickness of the shell composed of fluorinated graphene is 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com