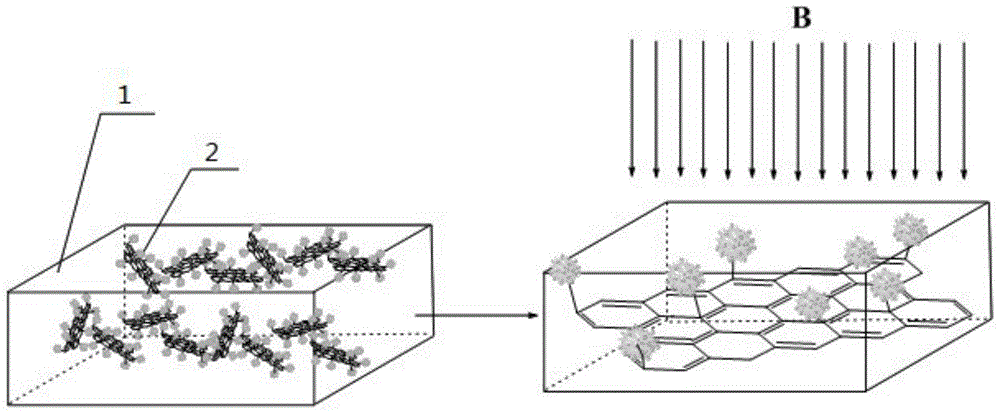

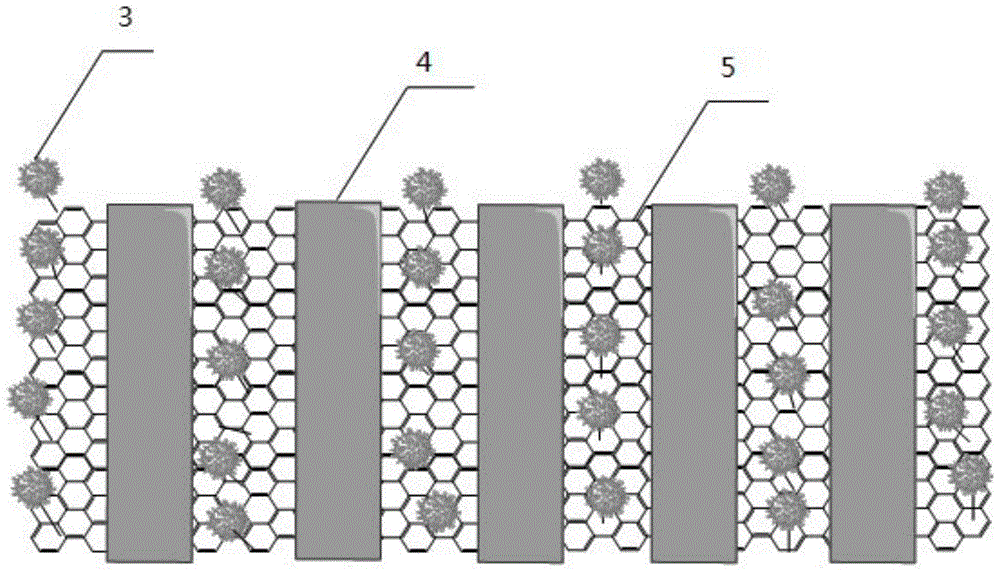

Polymers containing aligned magnetic graphene oxide sheets and methods for their preparation

A technology of orientation arrangement and oxide stone, applied in the polymer field of magnetic graphene oxide sheets, can solve the problems of inability to achieve barrier effect, lack of planar orientation structure, etc., and achieve high strength, tight surface structure, and improved mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

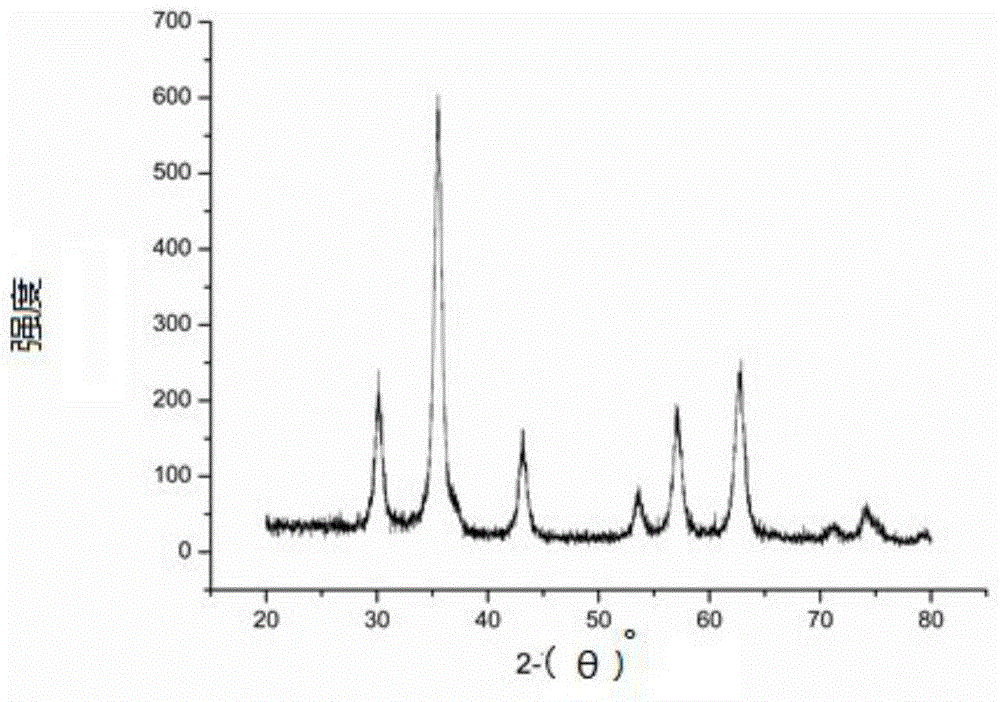

[0075] Weigh 10gP 2 o 5 , 10gK 2 S 2 o 8 Mix it in a 250ml beaker, put it into a magnet, and add 150g of 98% H with stirring in an ice bath. 2 SO 4 React until the system is clear, add 400mg of expanded graphite, and stir at 90°C for 4.5h. Cool the system in an ice bath, add 2000g of deionized water while stirring, filter with sand core funnel, wash the solid with deionized water until it is neutral, and dry it in a vacuum oven at 50°C. The amount of the above product is about 500mg, and add it to a three-necked flask In, add 184g weight concentration of 98% H 2 SO 4 To react, add 10g of potassium permanganate under ice bath stirring, react at 50°C for 2h, add 1000g deionized water under ice bath, transfer to a large beaker, add H2O dropwise under stirring 2 o 2 Until the system turns yellow, centrifuge, adjust the final pH value to 7, and dry to obtain graphene oxide;

[0076] Then 0.15g of graphene oxide and 0.05g of montmorillonite with a sheet diameter of 1-20nm ...

Embodiment 2

[0094] Weigh 10gP 2 o 5 , 10gK 2 S 2 o 8 Mix it in a 250ml beaker, put it into a magnet, and add 150g of 98% H with stirring in an ice bath. 2 SO 4 React until the system is clear (if not clear, heat it). Add 400mg of graphite (expanded graphite) and stir at 90°C for 4.5h. Cool the system in an ice bath, add 2000 g of deionized water while stirring, dilute to a certain extent, filter with sand core funnel, wash the solid with deionized water until the filtrate is nearly neutral, and dry in a vacuum oven at 50°C. The amount of above-mentioned product is about 500mg, adds in the there-necked flask, adds 184g weight concentration and is 98% H 2 SO 4 Reaction, slowly add 10g potassium permanganate (K 2 MnO 4 ), reacted at 50°C for 2h. Pour 1000g deionized water into the ice bath, transfer to a large beaker, add H2 dropwise under stirring 2 o 2 Until the system turns yellow, centrifuge, adjust the final pH value to 7, and dry to obtain graphene oxide.

[0095] Then di...

Embodiment 3

[0111] Weigh 10gP 2 o 5 , 10gK 2 S 2 o 8 Mix it in a 250ml beaker, put it into a magnet, and add 150g of 98% H with stirring in an ice bath. 2 SO 4React until the system is clear, add 400mg of expanded graphite, and stir at 90°C for 4.5h. Cool the system in an ice bath, add 2000g of deionized water while stirring, filter with sand core funnel, wash the solid with deionized water until it is neutral, and dry it in a vacuum oven at 50°C. The amount of the above product is about 500mg, and add it to a three-necked flask In, add 184g weight concentration of 98% H 2 SO 4 To react, add 10g of potassium permanganate under ice bath stirring, react at 50°C for 2h, add 1000g deionized water under ice bath, transfer to a large beaker, add H2O dropwise under stirring 2 o 2 Until the system turns yellow, centrifuge, adjust the final pH value to 7, and dry to obtain graphene oxide;

[0112] Then disperse 0.45g of graphene oxide and 0.2g of montmorillonite with a sheet diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com