Method for making high-embedding-ratio powder walnut oil

A technology of walnut oil and powder, which is applied in the field of preparing embedded walnut oil powder, which can solve the problems of low embedding rate and achieve the effects of improving nutritional value, ensuring storage performance, and rounding particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

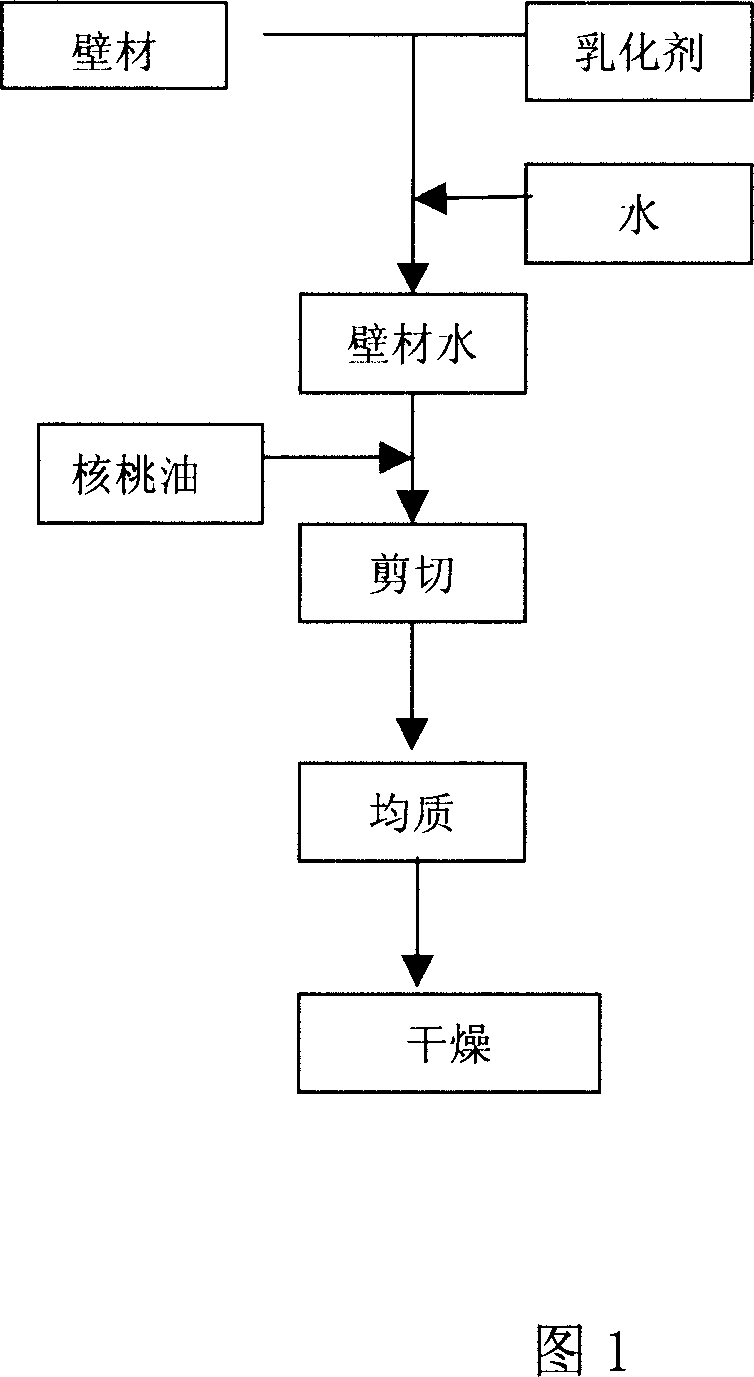

Image

Examples

Embodiment 1

[0018] Dissolve 2g of monoglyceride, 4g of lecithin and 1g of Tuwin-60 in 875g of demineralized water at a temperature of 50-70°C, and add 84g of octenyl succinic esterified starch HI-CAP100 and 126g in sequence while stirring Maltodextrin, dissolves evenly to form a wall material aqueous solution;

[0019] Add 140g of walnut oil to the above-mentioned wall material aqueous solution, and keep the temperature of the feed liquid at 50-70°C, pass through a colloid mill, and homogenize under high pressure for 2-3 times under a pressure of 35-40MPa;

[0020] Then, a centrifugal spray dryer is used to carry out spray drying at an air inlet temperature of 180-190°C and an outlet air temperature of 80-90°C to obtain a powdered walnut oil product. The microencapsulation efficiency of the walnut oil powder is 99.82%.

Embodiment 2

[0022] Prepare powdered walnut oil in the same manner as in Example 1, the difference being that used monoglyceride, lecithin, 1g soil temperature-60, demineralized water, octenyl succinic esterified starch HI-CAP100, maltodextrin and The weight of walnut oil is respectively 1g, 2g, 0.5g, 500g, 50g, 75g and 75g. The microencapsulation efficiency of the obtained powdered walnut oil was 95.52%.

Embodiment 3

[0024] Prepare powdered walnut oil in the same manner as in Example 1, the difference being that used monoglyceride, lecithin, 1g soil temperature-60, demineralized water, octenyl succinic esterified starch HI-CAP100, maltodextrin and The weight of walnut oil is respectively 3g, 6g, 9g, 1100g, 73g, 183g, 183g. The microencapsulation efficiency of the obtained powdered walnut oil was 90.28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com