Tire bead structure of tires

A bead and tire technology, applied in tire parts, bead, transportation and packaging, etc., can solve the problems of shortening tire bearing capacity and service life, achieve balanced stress and strain distribution, reasonable physical property matching, and reduce heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

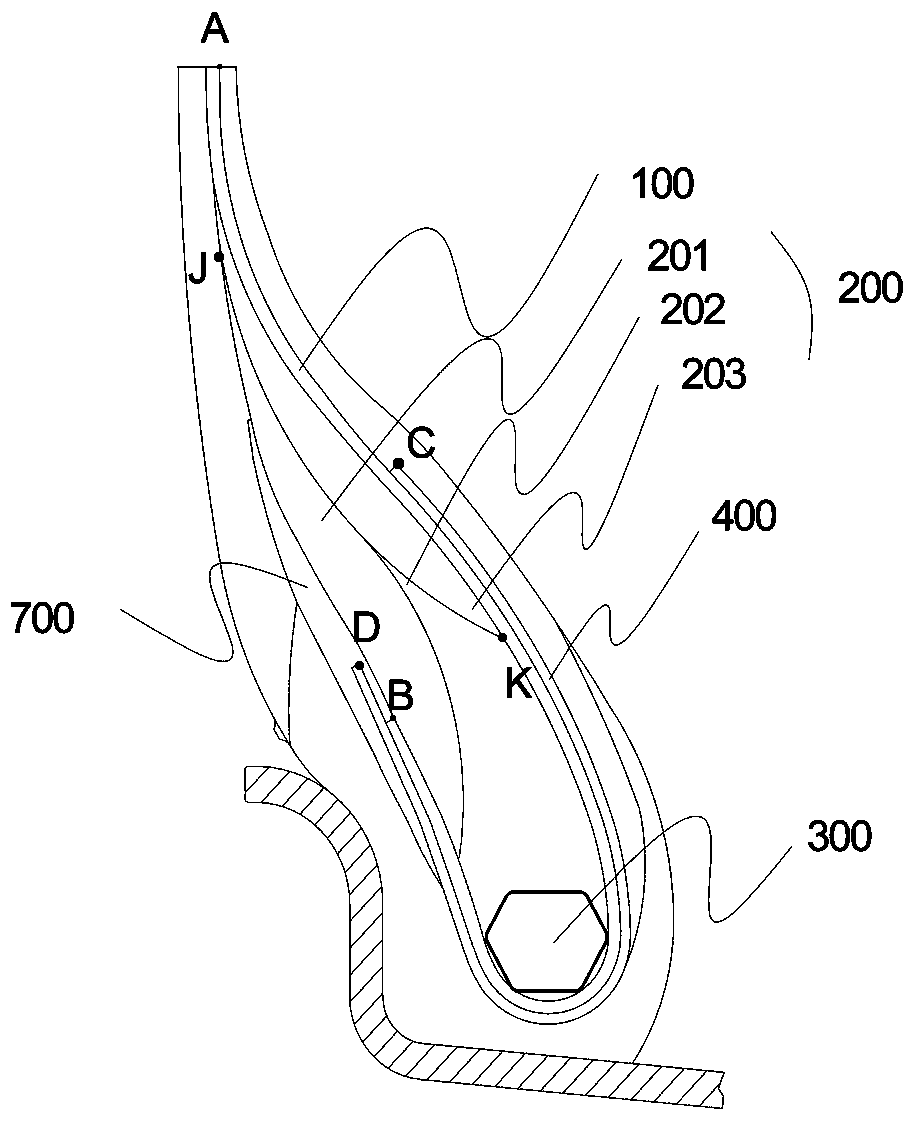

[0023] Please refer to this example figure 1

[0024] A tire bead structure, the bead includes a carcass 100, a bead core and sidewalls, the carcass 100 turns up around the bottom of the bead core to the outside of the bead core, the bead It also includes the first steel wire reinforcement layer 400 and transition glue 700;.

[0025] The bead core also includes a bead ring 300 and an apex rubber 200; the first steel wire reinforcement layer 400 wraps around the bottom of the bead ring 300 on the outside of the carcass 100; the transition rubber 700 is located Above the outer edge of the carcass 100 and between the apex 200 and the sidewall.

[0026] The inner endpoint of the carcass 100 is point A, the outer endpoint is point B, the outer endpoint of the first steel wire reinforcement layer 400 is point D, and the inner endpoint is point C;

[0027] The height difference between the outer end point D of the first steel wire reinforcement layer 400 and the outer end point B ...

Embodiment 2

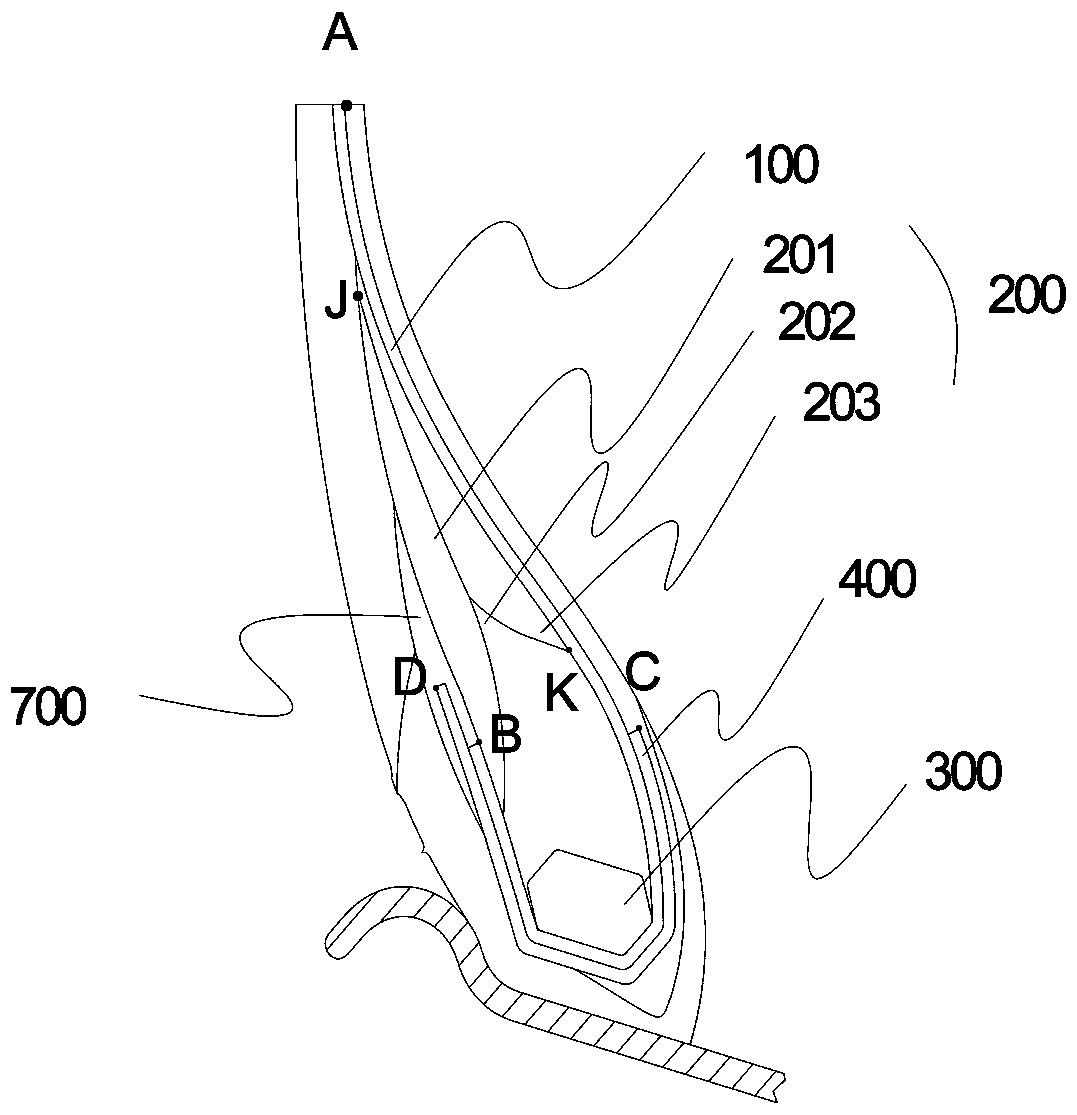

[0043] Please refer to this example figure 2

[0044] A tire bead structure, the bead includes a carcass 100, a bead core and sidewalls, the carcass 100 turns up around the bottom of the bead core to the outside of the bead core, the bead It also includes the first steel wire reinforcement layer 400 and the transition glue 700;

[0045] The bead core also includes a bead ring 300 and an apex rubber 200; the first steel wire reinforcement layer 400 wraps around the bottom of the bead ring 300 on the outside of the carcass 100; the transition rubber 700 is located Above the outer edge of the carcass 100 and between the apex 200 and the sidewall.

[0046] The inner endpoint of the carcass 100 is point A, the outer endpoint is point B, the outer endpoint of the first steel wire reinforcement layer 400 is point D, and the inner endpoint is point C;

[0047] The height difference between the outer endpoint D of the first steel wire reinforcement layer 400 and the outer endpoint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com